Struggling with inconsistent quality and high costs? Pushing for higher output but hitting a wall? The right annealing process[^1] turns these production challenges into your competitive advantage.

To achieve 10,000 tons/month of high-quality heat treatment, you must master the annealing process with equipment that ensures precise temperature (±3℃) and atmosphere (<10ppm O2) control. This boosts production by over 10% annually while maintaining product qualification rates above 99%, turning high volume into high value.

I've spent years helping manufacturers scale their operations. As the General Manager of AKS, I see firsthand how mastering this process separates the leaders from the rest. Let's break down how my team makes this high-volume, high-quality production a reality for our partners.

What Are the Basics of the Annealing Process?

Unsure how annealing really works? Worried that a misunderstanding of the fundamentals is causing defects and waste? Let's clarify the core principles for a solid foundation.

The annealing process is a heat treatment that alters a metal's microstructure to increase its ductility and reduce hardness. It involves three stages: heating to a specific temperature, holding it there (soaking), and then controlled cooling. Mastering these stages is essential for preventing defects.

I believe in keeping things simple. The entire goal of annealing is to make metal easier to work with. But simple goals require precise execution. Let's dive deeper into the three critical stages.

The Heating Stage

This is where we bring the metal, like stainless steel or copper, up to its recrystallization temperature[^2]. The goal is uniformity. Uneven heating leads to internal stresses and inconsistent grain structure, which means a weaker final product with poor formability. It's the foundation of the entire process, and getting it wrong means everything that follows is compromised.

The Soaking Stage

Once at temperature, the material needs to "soak." This holding period allows the new, stress-free grains to form and grow throughout the material. The duration depends entirely on the metal's thickness and type. Too short, and the process is incomplete. Too long, and you waste energy and risk excessive grain growth, which can harm mechanical properties.

The Cooling Stage

This is the most critical part for achieving the desired properties. The cooling rate must be controlled precisely. For bright annealing, this happens in a защитная атмосфера[^3] to prevent oxidation. Slow, controlled cooling is what ensures the material is soft and ductile. Rushing this step is a common mistake that undermines the entire process. At AKS, we designed our precision cooling system specifically to manage this stage flawlessly, ensuring a perfect finish every time.

How Do You Set Up Equipment for Optimal Performance?

Is your furnace setup holding you back? Constant adjustments and downtime kill productivity. Let's discuss how to configure your equipment for stable, 24/7 operation from the start.

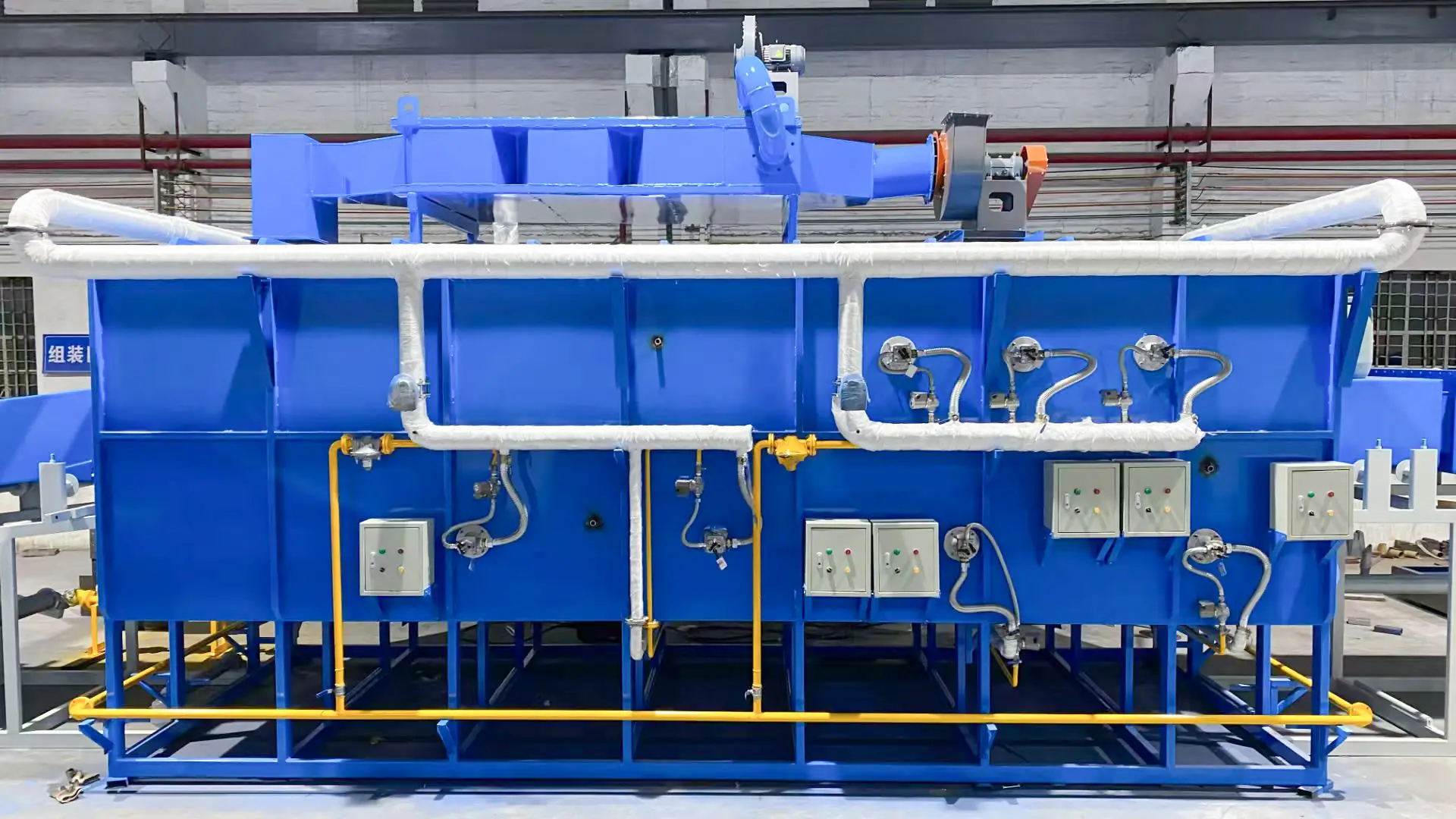

For optimal performance, set up your annealing furnace by ensuring proper calibration of all sensors, verifying the integrity of the furnace muffle, and integrating an efficient heat recovery system. This foundation enables stable 24/7 operation with over 98% uptime, directly boosting your annual production capacity.

I see many companies overlook the fundamentals of equipment setup. It's not just about turning it on. It's about creating a reliable production engine that works for you, not against you.

System Integration and Calibration

Before you run your first coil, every component must talk to each other correctly. This means calibrating temperature sensors and gas flow meters. An error of a few degrees here can ruin tons of material. We build our systems with integrated diagnostics to make this straightforward, removing guesswork and ensuring accuracy from the very beginning.

Energy Efficiency by Design

A key part of setup is optimizing for energy use. Our dual-layer heat recovery system, for example, isn't an add-on; it's integral. It captures waste heat from the exhaust to preheat the incoming air. This simple design feature is a major reason our clients see energy costs drop by 20-40%. It's about setting up for profitability from day one.

Customization for Your Needs

Standard equipment often fails because it's not made for your specific product. Over 70% of our orders are customized. We work with clients to set up furnaces that match their material, width, and speed requirements. This tailored setup is what prevents bottlenecks and ensures smooth, high-volume runs that standard, off-the-shelf solutions can't handle.

Why Is Implementing Precise Temperature and Atmosphere Control So Important?

Are you seeing oxidation or inconsistent hardness in your final product? These issues often stem from poor control. Let's look at why precision is non-negotiable for quality.

Precise temperature (±3℃) and atmosphere (<10ppm O2) control is critical because it directly determines the final mechanical properties and surface finish of the metal. It prevents oxidation, ensures uniform grain structure, and is the key to achieving product qualification rates over 99% consistently.

This is where the real magic happens, and it’s where most operations fail or succeed. You can have the best material in the world, but without precise control, you'll produce scrap.

The Role of Temperature Stability

A temperature swing of even 5-10 degrees can change the grain structure of the metal. Our furnaces maintain a stability of ±3℃ across the entire heating zone. This consistency is what allows our clients to run massive 10,000-ton-per-month schedules without worrying about quality deviations from the first coil to the last. It removes variability from the equation.

The Importance of Atmosphere Purity

For bright annealing, the goal is a mirror-like finish with zero oxidation. This requires a protective atmosphere with extremely low oxygen content[^4]. We guarantee an atmosphere with less than 10ppm of O2. This is achieved through a sealed muffle and precise gas management. It's the difference between a premium product and one that needs costly secondary cleaning processes like pickling.

How Technology Enables Control

We use an advanced fuel/air ratio control system[^5]. It constantly adjusts the mix to maintain the perfect combustion and furnace atmosphere. This isn't a manual "set it and forget it" process. It's an active, intelligent system that responds to changes in real-time to guarantee consistency and high efficiency.

How Should You Monitor and Adjust the Process for Consistency?

Does your process drift over a long run? Finding and fixing deviations too late is expensive. A proactive monitoring strategy is key to maintaining consistent, high-quality output.

Monitor your annealing process by tracking key data points in real-time: temperature zones, gas flow rates, and oxygen levels. Use this data to make small, immediate adjustments. This proactive approach ensures process stability, minimizes defects, and is essential for maintaining consistency across large production volumes.

A successful high-volume operation is not about a perfect initial setup. It's about maintaining that perfection over thousands of hours of continuous production.

Key Performance Indicators (KPIs) to Track

You must have a dashboard with live data. At a minimum, we advise our clients to track the temperature in each furnace zone, the protective gas consumption, the O2 ppm level at the exit, and the strip speed. These are the vital signs of your production line.

The Feedback Loop

Monitoring is useless without action. The data should feed into a clear process for making adjustments. For example, if the O2 level creeps up to 12ppm, the system should alert the operator to check for leaks or adjust gas flow. Our control systems automate much of this, but a trained operator is still vital. [Insert anecdote about a client's success in reducing defects] This is a great example of how monitoring leads to better outcomes.

Long-Term Reliability

This is also about equipment reliability. You can't have consistency if your furnace needs constant maintenance. We designed our furnaces for long-term industrial use, with a maintenance interval of at least 180 days. This stability is the foundation of a predictable, repeatable process.

How Do You Evaluate Results and Scale Up to 10,000 Tons/Month?

Ready to grow but worried about maintaining quality at a larger scale? Scaling isn't just about more volume. It's about scaling your process, efficiency, and profitability.

Evaluate results by measuring product qualification rates (>99%), energy consumption per ton, and overall equipment effectiveness (OEE). To scale to 10,000 tons/month, invest in reliable, customizable equipment designed for 24/7 operation. This ensures that increased output directly translates to increased profitability and market share.

Scaling up is the ultimate test of your process and your equipment. Here's how my most successful clients approach it.

Data-Driven Evaluation

First, they look at the numbers. What is their current qualification rate? How many kilowatts or cubic meters of gas are they using per ton of product? We provide our clients with the tools to track this. When they see a 20-40% reduction in energy costs and a qualification rate over 99%, they have a clear business case for scaling.

Choosing Scalable Technology

You cannot reach 10,000 tons with equipment that requires frequent downtime. Our furnaces are built for this kind of marathon. With over 98% uptime and long maintenance intervals, they are designed to be the reliable core of a high-volume production line. This reliability is the most important factor in scalable technology.

The Strategic ROI

Scaling is a strategic decision. It's about more than just production numbers. It's about market competitiveness. By boosting annual production by over 10% with our equipment, our clients can take on larger orders, serve new markets, and secure a more resilient future. It's an investment in capacity and capability.

Заключение

Mastering the annealing process is key to achieving 10,000 tons/month of quality output. It requires a deep understanding of the fundamentals, precise equipment control, and a focus on reliability. With the right technology and strategy, high-volume production becomes a powerful driver for your business growth.