Struggling to achieve consistent quality and optimal properties in your aluminum strips? The wrong annealing furnace can lead to material waste, production inefficiencies, and ultimately, dissatisfied customers. This often leaves manufacturers feeling frustrated and searching for a reliable solution to improve their output.

Imagine consistently producing perfectly annealed aluminum strips, meeting exact specifications for ductility, formability, and surface finish, thereby boosting your production yields and solidifying your market reputation. This isn't just a dream; it's achievable with the right equipment and knowledge.

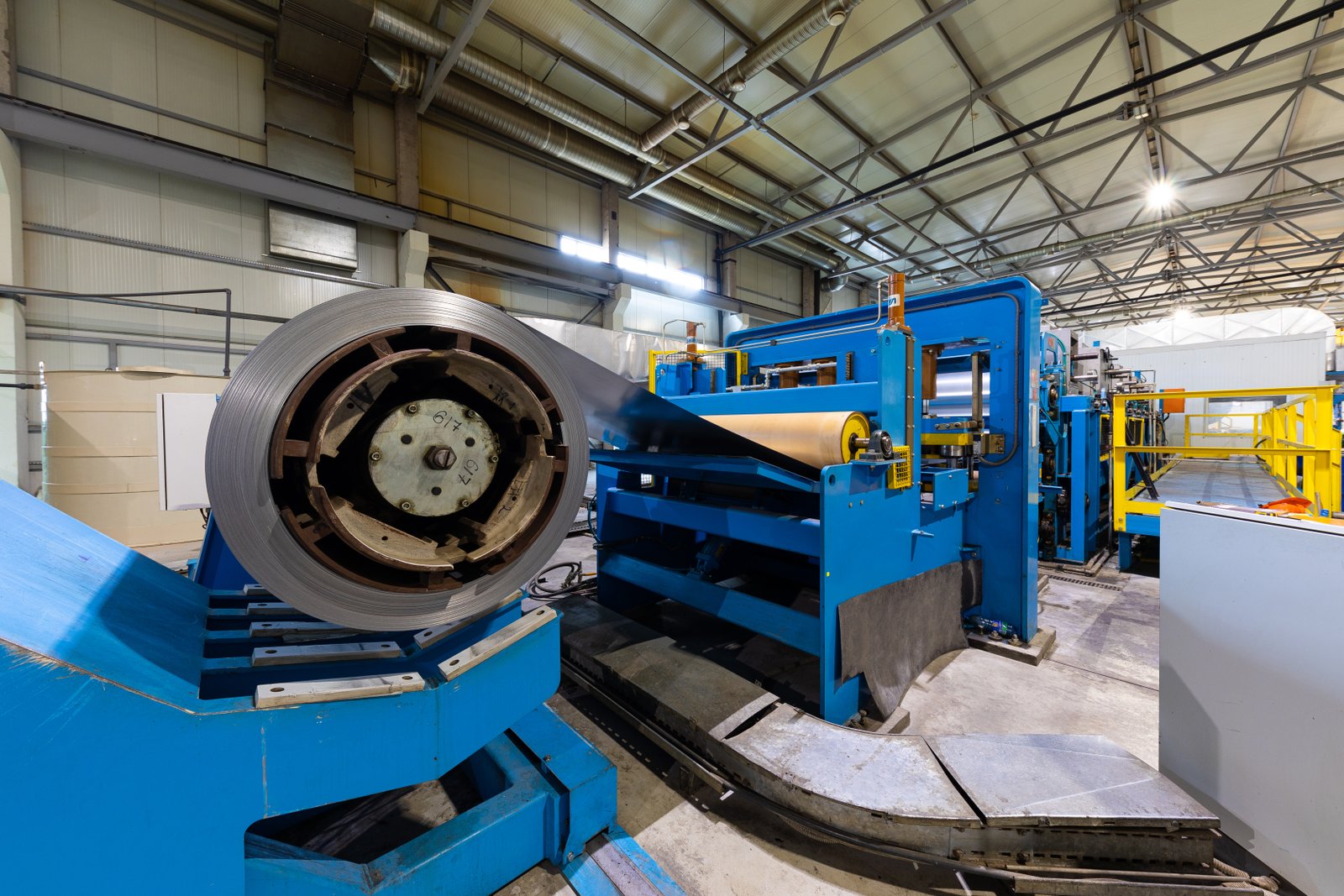

As Eric Tian from AKS Furnace, I've seen firsthand how the right annealing furnace can transform an aluminum strip production line. This guide will walk you through the critical considerations, helping you select a furnace that not only meets today's demands but also supports your future growth.

Choosing the right annealing furnace for aluminum strip production involves evaluating furnace types (e.g., continuous, batch), temperature uniformity, atmosphere control, and energy efficiency. These factors directly impact aluminum strip quality, including grain structure, mechanical properties, and surface finish, ensuring optimal performance for subsequent processing.

Making such a significant investment can seem daunting, with numerous technical specifications and operational variables to consider. You're likely pondering which furnace type best suits your specific aluminum alloys, what level of temperature precision is truly necessary, and how atmosphere control will affect your final product quality and operational costs. These are common concerns, and I've guided many clients through this exact decision-making process.

At AKS Furnace, we understand that an annealing furnace is more than just a piece of equipment; it's a cornerstone of your production quality and efficiency. The aluminum industry, especially in strip manufacturing for sectors like automotive, packaging, and construction, demands exceptional precision. A misstep in furnace selection can lead to issues like inconsistent hardness, poor drawability, or undesirable surface oxides, directly impacting your scrap rates and profitability. Conversely, a furnace tailored to your needs becomes a powerful asset. For instance, a client producing high-grade aluminum foil for sensitive food packaging applications significantly improved their product quality and reduced defects by investing in one of our continuous bright annealing furnaces equipped with advanced atmosphere control. This move not only enhanced their product but also opened up new market opportunities. This guide aims to equip you with the knowledge to make a similarly impactful decision.

What are the key facts about annealing furnaces for aluminum strip production?

Feeling uncertain about the fundamental requirements for annealing aluminum strips effectively? Misconceptions about temperature, atmosphere, or cycle times can lead to selecting an inefficient furnace, resulting in inconsistent product quality and increased operational costs, a common frustration for many manufacturers.

Imagine having a clear, concise understanding of the core principles involved. This knowledge empowers you to confidently discuss your needs with suppliers and select an annealing furnace that precisely matches your aluminum strip production requirements, ensuring optimal results.

Let's explore the essential facts about annealing furnaces specifically designed for aluminum strip production, clarifying their purpose, critical operational parameters, and how they contribute to achieving desired material properties.

Annealing furnaces for aluminum strip production primarily aim to soften the material, improve ductility, and relieve internal stresses by heating it to a specific temperature (typically 250-450°C for aluminum alloys) followed by controlled cooling. Key facts include the necessity for precise temperature uniformity and, often, a protective atmosphere to prevent oxidation and ensure surface quality.

Understanding these fundamental facts is crucial, but it's just the starting point. You might now be wondering, "How do these general principles apply to my specific aluminum alloys and production scale? And what are the real-world implications if one of these 'key facts' is overlooked?" I’ve seen this unfold many times. For example, a client in the automotive supply chain initially focused heavily on achieving the target annealing temperature for their 5xxx series aluminum strips but underestimated the impact of soak time variations within their older batch furnace. This led to inconsistent formability, causing issues in their stamping operations downstream. It became a clear lesson that all "key facts" – temperature, time, uniformity, atmosphere, and cooling rate – are interconnected and must be managed holistically. This understanding pushed them to consider a continuous annealing solution from AKS Furnace for better process control. We'll delve deeper into how these elements interplay within different furnace designs and what it means for the quality of your aluminum strips, your operational efficiency, and ultimately, your competitive edge in the market. This exploration will help you move from basic awareness to an informed, strategic approach in selecting your next annealing furnace.

The annealing of aluminum strips is a nuanced process, pivotal for achieving the desired mechanical properties and surface characteristics required for diverse applications, from deep-drawn beverage cans to intricate automotive components. The "facts" are not just academic; they have direct, tangible impacts on production yield, product quality, and operational costs. For instance, the relatively low annealing temperatures for aluminum (compared to steel) mean that precise control is even more critical, as small deviations can significantly alter properties. Furthermore, aluminum's high thermal conductivity can be both an advantage and a challenge in furnace design, requiring careful consideration of heat transfer mechanisms to ensure uniformity.

The Core Purpose: Metallurgical Transformation in Aluminum Annealing

Aluminum strip, especially after cold rolling, becomes work-hardened, exhibiting increased strength but significantly reduced ductility. The primary purpose of annealing is to reverse these effects through metallurgical processes like восстановление, рекристаллизация и рост зерен1. During heating, recovery allows for the rearrangement of dislocations into lower-energy configurations, slightly reducing internal stresses. As the temperature reaches the recrystallization point (typically 0.3 to 0.5 times the absolute melting point, varying by alloy and prior cold work – for many aluminum alloys, this is between 250°C and 450°C), new, strain-free grains nucleate and grow, replacing the deformed grain structure. This is the key transformation that restores ductility and softness. If held at temperature for too long, or at too high a temperature, excessive grain growth can occur, potentially leading to a rough surface finish ("orange peel" effect) after forming, or reduced fatigue strength.

I recall working with a client producing aluminum circles for cookware. Their initial annealing process, using a less controlled furnace, often resulted in either incomplete recrystallization (leading to cracking during deep drawing) or excessive grain growth (causing surface imperfections). By helping them understand the specific recrystallization kinetics of their AA1050 and AA3003 alloys and implementing a furnace with tighter temperature control and defined soak times, we were able to drastically reduce their defect rate. Industry data from sources like the European Aluminium Association highlights that achieving a fine, equiaxed grain structure through controlled annealing is paramount for applications requiring high formability and excellent surface quality. For example, a grain size of ASTM 7-9 is often targeted for deep drawing quality (DQ) aluminum sheets2.

The specific annealing cycle – heating rate, soak temperature, soak time, and cooling rate – must be tailored to the aluminum alloy and its intended application. For instance, 1xxx series (commercially pure aluminum) requires lower annealing temperatures compared to 5xxx series (Al-Mg alloys) or 6xxx series (Al-Mg-Si alloys) which might also undergo precipitation hardening and require specific solution treatment and aging cycles that can sometimes be combined with or follow annealing. Understanding these alloy-specific behaviors is a fundamental "fact" that dictates furnace design and operational parameters. At AKS Furnace, our design process always starts with a thorough understanding of the customer's material portfolio and desired end-properties.

Critical Parameters: Temperature Uniformity and Atmosphere Control

Temperature uniformity within the furnace chamber and across the aluminum strip itself is arguably the most critical parameter for successful annealing. Aluminum alloys are highly sensitive to temperature variations. A temperature difference of just ±5°C to ±10°C across the width or length of a coil can lead to significant variations in hardness, tensile strength, and elongation. This inconsistency translates directly into problems in downstream processes like stamping, deep drawing, or roll forming, leading to higher scrap rates and production inefficiencies. Modern annealing furnaces, like our AKS continuous lines, employ multiple, independently controlled heating zones, advanced high-convection systems, and precise thermocouple placements to achieve temperature uniformity often within ±3°C. For example, in the production of aluminum lithographic sheets, exceptional flatness and uniform mechanical properties are essential. A study by Novelis showed that improving temperature uniformity in their continuous annealing lines by just 2°C led to a measurable improvement in the consistency of these critical properties.

Atmosphere control is another non-negotiable aspect for many aluminum annealing applications, especially when a bright, oxide-free surface is required or when dealing with alloys sensitive to hydrogen pickup or high-temperature oxidation. While some alloys can be air-annealed if a certain level of surface oxide is acceptable, high-quality applications demand protective atmospheres. Pure nitrogen (N2) is common, offering an inert environment. For enhanced brightness and to counteract any trace oxygen, a mix of nitrogen and hydrogen (typically 2-5% H2, non-flammable)3 is often used, as hydrogen acts as a reducing agent. The furnace must be gas-tight, with reliable seals and precise control over gas flow rates and dew point. I remember a client in the electronics industry producing aluminum heat sinks. They initially struggled with inconsistent surface finish due to air ingress in their old furnace. Upgrading to an AKS furnace with a sealed muffle and precise N2 atmosphere control eliminated this issue, significantly improving the solderability and appearance of their products.

The choice of atmosphere impacts not only surface quality but also safety and operational costs. Hydrogen, while beneficial for surface brightness, requires careful handling and safety interlocks. The dew point of the furnace atmosphere is also critical; a high dew point (excess moisture) can lead to surface oxidation and hydrogen pickup in certain alloys, potentially causing blistering. Research published in the Журнал "Технология обработки материалов has shown that for bright annealing of AA1xxx series aluminum, maintaining a dew point below -40°C is often necessary to prevent surface dulling. This requires not only a good furnace design but also high-quality supply gas and proper furnace conditioning.

Furnace Types and Their Basic Operational Principles for Aluminum

Annealing furnaces for aluminum strip are broadly categorized into batch types and continuous types, each with distinct operational principles and suitability for different production scenarios. Batch furnaces, such as bell-type annealing furnaces or bogie hearth furnaces, process aluminum coils or sheets in discrete loads. A typical cycle involves loading the material, purging the furnace with protective atmosphere (if used), heating to soak temperature, holding for a specified time, and then controlled cooling before unloading. Bell furnaces, for example, often use a fixed base with a removable heating bell and a protective inner cover, allowing for efficient atmosphere control around the coil. These are versatile for varying coil sizes and alloys requiring different annealing cycles. A smaller specialty aluminum producer might opt for a bell furnace due to its flexibility. One of our clients producing various tempers of AA5052 for marine applications uses AKS bell annealers because they can easily adjust cycles for each customer's specific requirements.

Continuous annealing furnaces, on the other hand, process the aluminum strip as it moves uninterruptedly through different heating, soaking, and cooling zones. Examples include continuous strip annealers (often using catenary or flotation designs to support the strip), mesh belt furnaces for smaller parts or narrower strip, and our AKS Bright Annealing Furnace lines. These are designed for high throughput and consistent quality in large-scale production. The strip is uncoiled, fed through the furnace, and recoiled at the end. Each zone is precisely controlled for temperature and often atmosphere. The advantage is highly uniform annealing due to consistent exposure of every part of the strip to the same thermal cycle. For instance, a large aluminum rolling mill producing can body stock (e.g., AA3104) would typically use a high-capacity continuous annealing line capable of processing hundreds of tons per day. These lines often integrate cleaning, tension leveling, and inspection systems.

The choice between batch and continuous hinges on factors like production volume, alloy variety, strip dimensions, and capital investment. The table below provides a simplified comparison:

| Характеристика | Batch Annealing Furnace (e.g., Bell-Type) | Continuous Annealing Furnace (e.g., Strip Line) |

|---|---|---|

| Production Volume | От низкого до среднего | От высокого до очень высокого |

| Alloy/Cycle Flexibility | High (each batch can be different) | Lower (optimized for specific alloys/cycles) |

| Обработка полос | Coils are stationary | Strip moves continuously |

| Равномерность температуры | Good (with good design), but coil core-to-surface can be a challenge | Excellent (each part sees same cycle) |

| Atmosphere Consumption | Higher per ton (due to purging per cycle) | Lower per ton (continuous operation) |

| Энергоэффективность | Generally lower due to cyclic heating/cooling | Generally higher due to recuperation/steady state |

| Capital Cost (Typical) | Lower for small capacities | Higher, especially for integrated lines |

| Footprint | Can be more compact for given capacity | Larger, linear footprint |

Understanding these operational principles is key. A client producing thin aluminum foil for capacitors required extremely clean, bright surfaces and very tight thickness tolerances. A continuous bright annealing furnace from AKS, with its precise tension control and multi-zone heating/cooling under a high-purity nitrogen atmosphere, was the ideal solution, significantly improving their yield and product performance compared to their previous batch process. The consistent, gentle handling in a flotation furnace section also minimized strip damage.

Aluminum requires precise annealing temperaturesПравда

Aluminum's low annealing temperature range (250-450°C) demands tighter control than steel, as small deviations significantly affect material properties.

Batch furnaces always outperform continuous onesЛожь

Continuous furnaces provide superior temperature uniformity and efficiency for high-volume production, while batch furnaces offer flexibility for varied alloys.

How does furnace type affect the quality of aluminum strips?

Concerned that your current furnace type might be compromising the quality of your aluminum strips? Choosing between batch and continuous, or different heating methods, can feel like a gamble if the impacts on metallurgical properties and surface finish aren't clear.

Imagine confidently selecting a furnace type knowing precisely how it will influence your aluminum strip's grain structure, mechanical strength, formability, and surface brightness, leading to consistent, high-quality output that meets even the most demanding customer specifications.

Let's examine how different annealing furnace types – from batch to continuous, direct-fired to indirect-heated – directly affect the critical quality attributes of aluminum strips.

The furnace type significantly affects aluminum strip quality by influencing temperature uniformity, heating/cooling rates, and atmosphere control. Continuous furnaces generally offer better uniformity and consistency for high-volume production, while batch furnaces provide flexibility but may pose challenges in achieving consistent core-to-surface properties in coils.

The distinction between furnace types goes far beyond just how the material is loaded or moves. Each design philosophy—be it a robust bogie hearth for large, single coils, a versatile bell annealer, or a high-throughput continuous line—carries inherent characteristics that directly shape the final quality of your aluminum strip. You might be asking, "If a continuous furnace offers better uniformity, is it always the superior choice? Or are there scenarios where a batch furnace, despite its challenges, might be more appropriate for my specific aluminum alloys or quality targets?" This is a critical juncture in the decision process. I recall a project with a manufacturer of specialized architectural aluminum panels. They produced a wide variety of custom colors and finishes, often in smaller batches. While a continuous line promised excellent uniformity, its setup time and lower flexibility for diverse, short runs made a series of advanced AKS bell-type furnaces, equipped with enhanced convection and precise atmosphere control, a more practical and quality-effective solution for their business model. It highlights that "quality" is relative to the application and production context. We need to explore these nuances further to understand how specific furnace features translate into measurable quality outcomes for your aluminum strips.

The selection of an annealing furnace type is a pivotal decision that reverberates through every aspect of aluminum strip quality, from its microscopic grain structure to its macroscopic formability and surface aesthetics. It's not merely about heating and cooling; it's about orchestrating a precise thermal and atmospheric environment that coaxes the aluminum into its desired metallurgical state. Different furnace types achieve this with varying degrees of precision, efficiency, and suitability for specific aluminum alloys and production scales. Understanding these differences is key to producing high-quality aluminum strip consistently.

Impact of Continuous vs. Batch Processing on Temperature Uniformity and Consistency

Continuous annealing furnaces, such as roller hearth, catenary, or flotation types (like those in AKS Bright Annealing Lines), generally offer superior temperature uniformity and consistency compared to most batch furnaces when processing strip. In a continuous line, each segment of the strip experiences virtually the same time-temperature profile as it passes through dedicated heating, soaking, and cooling zones. This leads to highly consistent mechanical properties (hardness, tensile strength, elongation) along the entire length and across the width of the coil. For instance, aluminum strip destined for can body stock (e.g., AA3104) or automotive body panels (e.g., AA6xxx series) demands exceptionally tight tolerances on these properties. A study by the International Aluminium Journal highlighted that continuous annealing lines can achieve temperature uniformity of ±2°C to ±3°C across the strip width, which is critical for preventing issues like earing during deep drawing. Our AKS continuous furnaces are designed with multiple, small, independently controlled heating zones and high-convection systems precisely for this reason.

Batch furnaces, like bell annealers or bogie hearth furnaces, anneal stationary coils or stacks of sheets. While modern batch furnaces incorporate powerful fans and sophisticated baffle systems to improve heat transfer, achieving perfect temperature uniformity throughout a large, tightly wound aluminum coil can be challenging. The outer wraps heat and cool faster than the core, potentially leading to variations in grain size and mechanical properties from the surface to the center of the coil, and from edge to edge. This "coil effect" can be mitigated with carefully designed heating and cooling cycles, including extended soak times and programmed cooling, but it remains an inherent characteristic. For example, a client producing thick-gauge AA5083 aluminum plate for shipbuilding initially used an older bogie hearth furnace and struggled with hardness variations. While upgrading to an AKS bogie hearth with improved airflow and multi-point temperature monitoring significantly reduced the variation, the inherent physics of heating a large mass means it's a different challenge than a thin, moving strip. However, for smaller production runs or highly specialized alloys requiring very long, complex cycles not easily accommodated in a continuous line, a well-designed batch furnace remains a viable and cost-effective option.

The consistency between coils (batch-to-batch reproducibility) is also a factor. Continuous lines, once set up and stabilized, offer excellent reproducibility. Batch furnaces rely more on precise loading, consistent coil density, and meticulous cycle programming for each batch to achieve similar consistency. At AKS, we equip our batch furnaces with advanced PLC controls and data logging to help operators achieve this consistency, but it often requires more diligent process control compared to a continuous line running a stable product.

Role of Furnace Atmosphere and Heating Method on Surface Finish and Integrity

The type of furnace atmosphere (air, nitrogen, nitrogen-hydrogen mix) and the method of heating (direct-fired, indirect-fired, electric resistance) profoundly impact the surface quality of the aluminum strip. For applications demanding a bright, oxide-free, and clean surface – such as lithographic sheets, capacitor foil, or decorative architectural panels – a protective atmosphere is essential. Continuous bright annealing furnaces are typically designed with muffles or are inherently gas-tight, using N2 or N2/H2 atmospheres with low dew points (e.g., <-40°C). The hydrogen content (typically 2-5%) acts as a reducing agent, further cleaning the surface and ensuring maximum brightness. Electric heating or indirect gas-fired radiant tubes are preferred in such furnaces as they prevent combustion products from contaminating the strip surface. I worked with a producer of high-reflectivity aluminum sheet for lighting fixtures. Their switch from an older, direct-fired air annealer to an AKS electric continuous bright annealing line with a 97% N2 / 3% H2 atmosphere resulted in a measurable increase in reflectivity and a significant reduction in post-annealing cleaning steps.

In contrast, if a certain level of surface oxidation is acceptable or even desired (e.g., for paint adhesion on some construction materials), air annealing in a direct-fired or electric furnace might suffice. However, direct gas-fired furnaces, where combustion products come into contact with the strip, can lead to surface discoloration or contamination if the combustion is not perfectly controlled. This is particularly true for sensitive aluminum alloys. Even in batch furnaces using protective atmospheres, ensuring atmosphere integrity throughout the long heating and cooling cycle is critical. Bell annealers with well-sealed inner covers and effective purging cycles are crucial. For example, annealing coils of AA8xxx series fin stock for heat exchangers often requires a clean, moderately bright surface to ensure good thermal contact and brazeability. An AKS bell annealer with N2 atmosphere can achieve this, but careful monitoring of oxygen levels and dew point is vital.

The choice also influences material integrity beyond just the surface. For instance, some aluminum alloys, particularly those containing magnesium, can be susceptible to hydrogen embrittlement or blistering4 if annealed in atmospheres with excessive moisture or hydrogen under certain conditions. Proper furnace design and atmosphere control (e.g., managing dew point, using dry nitrogen) are critical to prevent such defects. Data from research bodies like The Minerals, Metals & Materials Society (TMS) often detail the complex interactions between aluminum alloys, furnace atmospheres, and resulting surface/sub-surface characteristics.

Influence of Heating and Cooling Rates on Grain Structure and Mechanical Properties

The rates at which aluminum strip is heated to the annealing temperature and subsequently cooled play a crucial role in determining the final grain size, texture, and mechanical properties. Different furnace types offer varying degrees of control over these rates. Continuous annealing lines typically feature distinct, optimized zones for rapid heating, precise soaking, and controlled cooling (which can be rapid or slow, depending on the alloy and desired properties). Rapid heating can help refine grain size in some alloys, while controlled cooling is essential for others to prevent uncontrolled precipitation or to achieve specific tempers (e.g., T4 temper in 6xxx series alloys often requires rapid cooling after solution treatment5, which is a form of annealing). For instance, a continuous line for automotive AA6xxx alloy strip might incorporate a rapid gas jet or water quench cooling section. Our AKS lines can be customized with various cooling technologies based on these metallurgical requirements.

Batch furnaces inherently have slower heating and cooling rates due to the thermal mass of the coil and the furnace itself. While this can be advantageous for stress relieving thick sections or for alloys prone to distortion with rapid temperature changes, it can also lead to coarser grain sizes if not properly managed. For example, a large coil of AA1100 aluminum annealed in a batch furnace will cool much slower at its core than at its surface. This differential cooling can result in a gradient of properties. However, for certain O-temper (fully soft) applications, a slow cool is perfectly acceptable or even desirable. A client producing soft temper aluminum wire from rod (which is then drawn and annealed) found that the slower, more uniform cooling in their AKS bell annealer (relative to a faster, less controlled method they used previously) resulted in more consistent elongation values, improving drawability in subsequent fine-wire drawing stages.

The ability to precisely control these rates is a hallmark of a quality furnace. The table below shows a general comparison of how furnace types relate to heating/cooling control:

| Тип печи | Typical Heating Rate Control | Typical Cooling Rate Control | Impact on Grain Size |

|---|---|---|---|

| Continuous Strip Annealer | High (multiple zones, rapid) | High (dedicated cooling sections) | Can achieve fine grains; highly controllable |

| Печь с сетчатой лентой (непрерывного действия) | От умеренного до высокого | Moderate (air, gas jet) | Good for smaller parts, consistent results |

| Bell Annealer (Batch) | Slow to Moderate | Slow (furnace cool, fan assist) | Generally coarser grains than rapid cool; good uniformity with time |

| Печь-очаг Bogie (Batch) | Медленный | Very Slow (furnace cool) | Often results in larger grains; suitable for stress relief |

| Вакуумная печь для отжига (периодического действия) | Moderate (radiation/convection) | Moderate to Slow (gas quench/cool) | Excellent surface purity; grain size depends on cycle |

Understanding these relationships is vital. For instance, if producing an aluminum alloy that benefits from a specific quench rate to achieve optimal strength after age hardening (like some 6xxx series alloys), a continuous line with an integrated quenching system or a specialized batch quench furnace would be necessary. Simply annealing in a standard batch furnace with slow cooling would not yield the desired properties.

Continuous furnaces offer better temperature uniformityПравда

Continuous annealing lines maintain ±2-3°C uniformity across strip width due to dedicated heating/cooling zones.

Batch furnaces always produce inferior qualityЛожь

Modern batch furnaces with advanced controls can achieve excellent quality for specialized alloys or small batches.

What are the critical factors to consider when selecting an annealing furnace?

Overwhelmed by the myriad of specifications when trying to select an annealing furnace for your aluminum strips? Focusing on the wrong parameters can lead to a costly mismatch between the furnace's capabilities and your actual production needs and quality targets.

Imagine confidently navigating the selection process, armed with a clear understanding of the most critical factors. This empowers you to choose a furnace that not only performs optimally but also delivers a strong return on investment for your aluminum strip operations.

Let's pinpoint the absolutely critical factors you must consider, from capacity and temperature control to atmosphere systems and long-term operational costs, ensuring your choice is well-informed.

Critical factors for selecting an aluminum strip annealing furnace include matching furnace capacity to production volume, ensuring precise temperature control and uniformity (typically ±3-5°C), evaluating atmosphere system capabilities for surface quality, considering energy efficiency, and assessing overall total cost of ownership.

Identifying these critical factors is the first step towards making a sound investment. However, each factor carries its own set of nuances and trade-offs that need careful evaluation in the context of your specific aluminum strip products and business goals. You might be thinking, "How do I accurately calculate the required capacity, especially if my production forecasts fluctuate? Or what level of temperature uniformity is 'good enough' for my particular alloys without overspending on unnecessary precision?" These are practical questions I often discuss with clients. I recall a rapidly growing aluminum foil manufacturer in India who was tempted by a very large-capacity furnace, thinking it would future-proof their operations. However, after a detailed analysis with our AKS team, we determined that two medium-capacity, high-efficiency continuous lines would offer them better operational flexibility, redundancy, and a quicker return on investment by allowing phased capacity ramp-up matching their market growth. This experience underscores that "critical factors" must be weighed and balanced. Let's delve deeper into each of these critical considerations to provide you with a robust framework for your decision-making.

Selecting the right annealing furnace for aluminum strip production is a strategic decision with long-term implications for your operational efficiency, product quality, and profitability. It’s not just about buying a machine that heats metal; it’s about investing in a solution that integrates seamlessly into your production flow and consistently delivers the desired metallurgical outcomes. A methodical approach, focusing on truly critical factors, is essential. At AKS Furnace, we guide our clients through this process, ensuring they consider not just the initial purchase price but the entire lifecycle value.

Matching Furnace Capacity and Design to Production Volume and Strip Specifications

The most fundamental factor is ensuring the furnace's capacity aligns with your current and projected production volumes. Oversizing a furnace can lead to inefficiencies (e.g., running a large continuous furnace for small, infrequent batches wastes energy and setup time), while undersizing creates bottlenecks and limits growth. For continuous furnaces, capacity is typically defined in tons/hour or meters/minute based on specific strip dimensions (width, thickness) and annealing cycle times. For batch furnaces, it's about coil weight capacity and the number of cycles achievable per day. I always advise clients to perform a thorough analysis of their product mix. For instance, a client producing primarily thin-gauge aluminum foil (e.g., 6-20 microns) will have different throughput considerations (often speed-limited) compared to one producing thicker strip (e.g., 1-3 mm, often weight-limited). Calculating the required net throughput, considering typical downtimes for maintenance and product changeovers, is crucial.

Beyond sheer volume, the furnace design must accommodate your range of strip specifications. This includes minimum and maximum strip width, thickness, and coil weight. For continuous lines, strip tension control capabilities are vital, especially for thin or very wide strips, to prevent breakages or deformation. The choice between, say, catenary vs. flotation furnace designs6 (where the strip sags slightly in a catenary setup, versus being supported by gas jets in a flotation one) can depend on the sensitivity of the strip surface and the required tension levels. For batch furnaces, consider the maximum coil diameter and weight the loading mechanisms and furnace chamber can handle. A practical example: a client processing very wide (e.g., >2000mm) aluminum strip for architectural applications needed a continuous furnace with exceptionally robust edge support and steering systems to maintain strip stability and prevent edge damage, a key design consideration we incorporated into their AKS furnace.

Furthermore, consider the material flow and plant layout. A continuous annealing line requires significant linear space and integration with upstream (e.g., rolling mill, cleaning section) and downstream (e.g., tension leveler, inspection, recoiler) equipment. Batch furnace installations might offer more flexibility in layout but require efficient material handling systems for loading and unloading heavy coils. We often create 3D plant layout simulations for our clients at AKS to ensure the chosen furnace integrates optimally within their existing or planned facility, minimizing material travel and maximizing workflow efficiency. This foresight prevents costly modifications later.

Evaluating Temperature Control Precision, Uniformity, and Range

For aluminum annealing, precise temperature control and uniformity are non-negotiable for achieving consistent metallurgical properties. Aluminum alloys have relatively narrow optimal annealing windows; deviations of even ±5°C can significantly affect hardness, ductility, and grain structure. You must critically evaluate a furnace's ability to achieve and maintain the required temperature uniformity (typically specified as ±3°C to ±5°C across the strip or within the load) throughout the soak period. This involves looking at the number and placement of thermocouples, the design of heating elements (electric or gas-fired radiant tubes), the sophistication of the PID control loops, and the effectiveness of atmosphere circulation systems (e.g., high-convection fans, jet plenums). A client producing aerospace-grade aluminum alloys, requiring extremely tight property tolerances, opted for an AKS furnace with a multi-zone radiant tube heating system and advanced CFD-modelled convection, which demonstrated temperature uniformity better than ±2°C in qualification trials.

The required temperature range is also important. While most aluminum annealing occurs between 250°C and 450°C, some specialized alloys or processes (like solution heat treatment for 6xxx or 7xxx series, which often precedes aging) might require higher temperatures (e.g., up to 550°C). Ensure the furnace is capable of reaching these temperatures efficiently and maintaining uniformity at both the lower and upper ends of your processing range. The heating and cooling rates achievable are also part of this consideration, as discussed earlier. For example, if you need to perform partial annealing or stress relieving at lower temperatures for some products and full annealing at higher temperatures for others, the furnace must offer precise control across this spectrum.

Data logging and reporting capabilities are essential for quality assurance and process traceability. Modern furnaces should provide comprehensive data on temperature profiles, soak times, and any deviations, allowing for continuous process monitoring and optimization. When we commissioned a continuous annealing line for a major aluminum strip supplier to the automotive sector, their OEM customers mandated detailed thermal processing records for every coil. The integrated data acquisition system in their AKS furnace was a critical factor in meeting this requirement.

Assessing Atmosphere System Capabilities, Gas Consumption, and Safety

If your aluminum products require a bright, oxide-free surface, or if you're processing alloys sensitive to atmospheric reactions, the furnace's protective atmosphere system is a critical factor. Evaluate the furnace's gas-tightness (leak rates), the type of atmosphere it can handle (e.g., 100% N2, N2/H2 blends, exothermic/endothermic gases if applicable, though less common for aluminum), and the precision of atmosphere control (e.g., flow rates, dew point monitoring, oxygen analysis). For bright annealing, as I've mentioned, low dew points (e.g., -40°C to -60°C) and low oxygen levels (e.g., <10-50 ppm) are typically required. Achieving this consistently depends on furnace construction (e.g., welded muffle, robust seals), quality of atmosphere supply, and effective purging procedures. A client producing mirror-finish aluminum reflectors found that the superior seal design and multi-stage purging sequence in their AKS bright annealing furnace significantly reduced their nitrogen consumption while achieving a better surface finish compared to their older unit.

Gas consumption is a significant operational cost. Look for furnaces with features designed to minimize gas usage, such as efficient sealing, atmosphere recirculation and purification systems (where feasible), and optimized purging cycles. The table below compares typical atmosphere considerations for different surface requirements:

| Desired Surface Finish | Typical Atmosphere | Key Furnace Features for Atmosphere | Relative Gas Consumption |

|---|---|---|---|

| Matte / Standard | Air (sometimes) | Good temperature control, possibly direct fired | N/A (if air) / Low |

| Clean, Mill Finish | Азот (N2) | Gas-tight design, good seals, N2 inlet/outlet control | Умеренный |

| Bright Finish | Nitrogen/Hydrogen (N2/H2) or high-purity N2 | Muffle or retort, excellent seals, low dew point, O2 monitoring | От умеренного до высокого |

| Ultra-Bright/Reflective | High-purity N2/H2 mix | Premium seals, advanced purging, atmosphere recirculation | Высокий |

Safety is paramount, especially when using hydrogen-containing atmospheres. Ensure the furnace complies with relevant safety standards (e.g., NFPA 86 in North America, EN 746-3 in Europe) and includes features like flame supervision systems (for H2 burn-off), emergency purge systems, gas leak detectors, and proper ventilation. At AKS, all our furnaces designed for combustible or asphyxiant atmospheres incorporate comprehensive safety interlocks and control systems. We always conduct a thorough safety review with the client's team as part of the installation and commissioning process.

Temperature uniformity is critical for aluminum annealingПравда

Aluminum alloys require tight temperature control (±3-5°C) to achieve consistent metallurgical properties, as even small deviations can affect hardness and grain structure.

Larger furnaces always offer better ROIЛожь

Oversized furnaces can be inefficient for small batches, and multiple medium-capacity units often provide better flexibility and faster ROI by matching production growth.

Worried about high energy bills and operational costs cutting into your profits from aluminum strip production? Simply looking at the purchase price of an annealing furnace doesn't reveal its true long-term efficiency or cost-effectiveness.

Imagine being able to accurately assess and compare the true efficiency of various annealing furnace options. This would allow you to select a system that minimizes energy consumption, reduces operational expenses, and maximizes your return on investment over its entire lifespan.

Let's explore practical methods for evaluating furnace efficiency, focusing on energy usage, total cost of ownership, and automation's impact on productivity.

Manufacturers can evaluate annealing furnace efficiency by analyzing specific energy consumption (kWh/ton or m³/ton), thermal efficiency ratings, recuperation/regeneration capabilities, insulation quality, and by calculating the Total Cost of Ownership (TCO), which includes maintenance, consumables, and labor impact, not just initial price.

Evaluating efficiency is more than just comparing numbers on a spec sheet; it requires a holistic view of how the furnace will perform in your specific operational context. You might be asking, "How can I reliably compare energy consumption figures from different suppliers, especially if their test conditions vary? And what are the hidden costs that contribute to the Total Cost of Ownership that I might be overlooking?" These are vital questions. I often share an experience with a client who was initially attracted to a lower-priced furnace from a lesser-known supplier. However, when we at AKS helped them conduct a thorough TCO analysis, factoring in the competitor's higher projected energy usage, shorter component lifespans, and limited local support, it became clear that our slightly higher-priced but more efficient and durable AKS furnace would offer significantly lower operational costs and better overall value within just a few years. This highlights the importance of looking beyond the sticker price. Let's break down how you can systematically assess these efficiency aspects to make a truly informed decision.

In today's competitive aluminum strip market, operational efficiency is paramount. An annealing furnace is a significant energy consumer and its overall efficiency directly impacts production costs and environmental footprint. A thorough evaluation process should extend far beyond the initial capital outlay to encompass all aspects of performance and long-term cost. At AKS Furnace, we champion a data-driven approach to help our clients quantify these efficiencies, enabling them to make choices that are both economically and environmentally sound.

Analyzing Energy Consumption (kWh/ton or Therms/ton) and Thermal Efficiency

The most direct measure of energy efficiency is the specific energy consumption (SEC)7, typically expressed in kilowatt-hours per ton (kWh/ton) for electrically heated furnaces, or cubic meters/cubic feet/therms of gas per ton for fuel-fired furnaces. When comparing SEC figures from different manufacturers, ensure they are based on comparable operating conditions: the same aluminum alloy, strip dimensions, annealing temperature, and throughput. Reputable suppliers like AKS provide SEC data based on standardized conditions or can estimate it for your specific process. For example, a modern continuous bright annealing line for aluminum strip might target an SEC of 150-250 kWh/ton, depending on strip thickness and line speed, whereas older or less optimized designs could be significantly higher. I recall a client who upgraded from an old batch annealing system (SEC around 400 kWh/ton) to an AKS continuous line and saw their energy costs for annealing drop by nearly 40%.

Thermal efficiency is another key metric, representing the percentage of heat input that is actually used to heat the product and compensate for steady-state losses, versus heat lost through exhaust gases, furnace walls, openings, etc. Look for furnaces with high-quality insulation (e.g., multi-layer ceramic fiber modules with low thermal conductivity), effective door seals, and, for fuel-fired furnaces, advanced burner technology (e.g., regenerative or recuperative burners that recover heat from exhaust gases to preheat combustion air). Recuperators can recover 20-40% of waste heat, while regenerative systems can achieve even higher efficiencies (50-70%). For instance, an AKS fuel-fired continuous furnace equipped with recuperative burners might boast a thermal efficiency of over 70%, compared to 40-50% for older designs without heat recovery.

It's also important to consider energy consumption during idling or standby periods, as furnaces are not always running at full capacity. Furnaces with good turndown ratios (ability to operate efficiently at lower outputs) and quick ramp-up/cool-down capabilities can save significant energy during production gaps. We often advise clients to track not just peak load efficiency but overall energy use patterns to identify areas for improvement.

Calculating Total Cost of Ownership (TCO) Including Maintenance and Consumables

The initial purchase price of a furnace is only one component of its total cost over its lifespan. A comprehensive Total Cost of Ownership (TCO) analysis provides a much truer picture of efficiency and value. TCO includes:

- Capital Expenditure (CAPEX): Initial purchase price, installation, commissioning.

- Operational Expenditure (OPEX):

- Energy Costs: Electricity and/or fuel, based on SEC and projected usage.

- Atmosphere Gas Costs: Nitrogen, hydrogen, etc. Consumption rates and gas prices.

- Consumables: Spare parts like heating elements, thermocouples, radiant tubes, conveyor belts (for mesh belt furnaces), seals, refractory repairs. Frequency of replacement and cost.

- Maintenance Costs: Labor for routine and corrective maintenance. Consider the furnace's design for maintainability (e.g., ease of access to components).

- Labor Costs: Operator requirements. Higher automation can reduce labor input.

- Downtime Costs: Lost production due to scheduled and unscheduled maintenance. Reliability is key.

I worked with a large aluminum strip processor who was comparing two continuous annealing lines. While one had a 10% lower initial price, our TCO model for the AKS line, which factored in its superior energy efficiency, longer-lasting radiant tubes (made from a proprietary alloy), and lower projected maintenance needs, showed a break-even point within 3 years, with significant savings accumulating thereafter. They ultimately chose the AKS line based on this long-term value proposition.

The lifespan and reliability of critical components are major TCO drivers. For electric furnaces, heating element life is crucial. For fuel-fired furnaces, burner and radiant tube longevity are important. At AKS, we use high-quality materials and robust designs to maximize component life, reducing replacement frequency and associated costs. For instance, our SiC or advanced metallic alloy radiant tubes often last significantly longer than conventional ones.

Assessing Automation Levels and Their Impact on Labor Costs, Productivity, and Quality

The level of automation integrated into the annealing furnace significantly impacts operational efficiency, labor costs, product quality, and consistency. Modern furnaces often feature advanced PLC-based control systems with HMIs (Human-Machine Interfaces) that automate temperature profiling, atmosphere control, strip tension (in continuous lines), data logging, and fault diagnostics. Higher automation reduces the need for constant operator intervention, minimizes the risk of human error, and allows for more precise and repeatable process control. This leads to more consistent product quality and reduced scrap rates. For example, an AKS continuous annealing line with fully automated coil handling, recipe management, and real-time process monitoring can be run with fewer operators compared to a more manually intensive system, directly impacting labor costs per ton of aluminum processed.

Automation also enhances productivity. Features like automatic startup and shutdown sequences, predictive maintenance alerts (based on sensor data), and remote monitoring capabilities can minimize downtime and optimize furnace utilization. A client producing aluminum foil for packaging implemented an AKS line with advanced automation. The system's ability to automatically adjust process parameters based on incoming strip characteristics (fed from an upstream sensor) and to provide early warnings for potential issues significantly improved their overall equipment effectiveness (OEE)8 and reduced instances of off-spec material.

The table below outlines some automation features and their efficiency benefits:

| Automation Feature | Impact on Labor Cost | Impact on Productivity | Impact on Quality Consistency |

|---|---|---|---|

| PLC Control with Recipe Management | Reduced (less manual setup) | Increased (faster changeovers) | High (repeatable cycles) |

| Automated Temperature & Atmosphere Control | Reduced (less monitoring) | Increased (optimal conditions) | Very High (tight control) |

| Integrated Data Logging & Reporting | Neutral / Slight Increase (analysis) | Increased (process insights) | High (traceability, optimization) |

| Automated Coil Handling (Continuous) | Significantly Reduced | Significantly Increased | Improved (less damage) |

| Predictive Maintenance Alerts | Reduced (planned vs. unplanned) | Increased (less unexpected downtime) | Maintained (prevents degradation) |

| Remote Monitoring & Diagnostics | Reduced (faster support) | Increased (quicker issue resolution) | Maintained (proactive support) |

When evaluating efficiency, consider the entire system. A furnace that is highly energy-efficient but requires frequent, complex maintenance or extensive manual operation may not be the most cost-effective solution in the long run. A balanced approach, weighing energy performance, TCO, and the productivity gains from appropriate automation, will lead to the best investment.

Specific energy consumption measures furnace efficiencyПравда

SEC (kWh/ton) directly compares how much energy different furnaces need to process the same amount of material.

Purchase price determines total furnace costЛожь

TCO includes energy, maintenance, labor and downtime costs over the furnace's lifespan, not just initial price.

What recommendations can help in selecting the ideal annealing furnace for specific production needs?

Feeling uncertain about making the final decision on an annealing furnace, fearing you might overlook a critical detail for your specific aluminum strip production? The complexity of matching furnace capabilities to unique operational requirements can be a significant hurdle.

Imagine having a clear, actionable set of recommendations to guide you through the final stages of selecting the ideal annealing furnace. This would ensure your choice perfectly aligns with your current and future production needs, guaranteeing quality, efficiency, and profitability.

Let me share key recommendations, from deeply understanding your material specifications to leveraging supplier expertise and planning for future growth.

To select the ideal annealing furnace, manufacturers should meticulously define their aluminum alloy portfolio and precise quality specifications, conduct pilot tests if possible, thoroughly vet supplier expertise and after-sales support, and consider future scalability and technological adaptability of the furnace.

These recommendations serve as a roadmap to navigate the complexities of furnace selection, ensuring your final choice is not just a purchase, but a strategic investment tailored to your unique operational landscape. You might be thinking, "Defining specifications is straightforward, but how do I truly assess a supplier's expertise beyond their sales pitch, or effectively plan for future needs that are still somewhat uncertain?" These are common and valid concerns. I often recall a client, a mid-sized aluminum component manufacturer, who was expanding their product line. They initially focused only on their current needs. However, by working with them through the AKS consultative process, we helped them anticipate upcoming demands for new alloys requiring different annealing cycles. This foresight led to selecting a slightly more versatile furnace model, which saved them significant reinvestment costs just two years later. This illustrates that a holistic, forward-thinking approach, guided by experience, is crucial. Let's explore these recommendations in greater detail to equip you for making the best possible decision.

Choosing the ideal annealing furnace is a culmination of careful analysis, technical understanding, and strategic foresight. It's about finding the perfect synergy between your specific aluminum strip production requirements and the capabilities of the available technology. The following recommendations are distilled from years of experience at AKS Furnace, helping clients across various sectors make informed decisions that drive their success. These steps are designed to move you from general consideration to confident selection.

Defining Your Aluminum Alloy Portfolio, Throughput Requirements, and Critical Quality Specifications

The absolute starting point is a comprehensive understanding of what you are annealing and why. Create a detailed matrix of all aluminum alloys you currently process or plan to process. For each alloy, document:

- Alloy Designation: (e.g., AA1100, AA3003, AA5052, AA6061)

- Incoming Condition: (e.g., H18, H24 – degree of cold work)

- Desired Final Temper/Properties: (e.g., O-temper, specific tensile strength, elongation, hardness, grain size target like ASTM E1129)

- Critical Quality Specifications: Surface brightness (e.g., reflective, matte, clean), surface roughness, freedom from defects (e.g., oil stains, blisters, oxidation), dimensional stability.

- Strip Dimensions: Range of thicknesses, widths.

- Production Volume per Alloy: Current and projected (e.g., tons/month).

This detailed definition will directly inform the required furnace temperature range, atmosphere type, cycle times, heating/cooling rate capabilities, and overall capacity. For instance, a client producing primarily 1xxx series aluminum for decorative applications will prioritize furnaces capable of achieving ultra-bright finishes with N2/H2 atmospheres and precise, lower-temperature annealing. In contrast, a client annealing 5xxx series for structural components might focus more on achieving specific mechanical strength and formability, possibly with different atmosphere needs. I always tell my clients at AKS, "The more precisely you define your needs, the better we can tailor a solution." Lack of clarity here is the primary reason for furnace mismatches. For example, if a fine grain size is critical for subsequent forming operations, this must be specified, as it influences the required heating/cooling rates and soak times, and thus the furnace design.

Don't forget to consider industry-specific standards or customer mandates. Automotive, aerospace, and food packaging sectors often have stringent quality requirements (e.g., NADCAP for aerospace10, FDA compliance for food contact materials) that the annealed product and the annealing process itself must meet. This might dictate specific furnace features, such as advanced data logging, material traceability, or certifications.

Conducting Pilot Tests, Thoroughly Vetting Supplier Expertise, and Prioritizing After-Sales Support

Whenever possible, especially for critical applications or new alloys, conducting pilot tests on a prospective supplier’s furnace (or a similar model) can provide invaluable data. This allows you to verify if the furnace can achieve your desired metallurgical properties and surface finish with your specific material. Many reputable furnace manufacturers, including AKS Furnace, have R&D facilities or partnerships where such trials can be arranged. We recently worked with a client developing a new type of aluminum composite panel. We conducted several annealing trials on their sample materials in our lab furnace, varying temperature profiles and atmospheres, until we optimized a cycle that met their stringent bonding and formability requirements. This de-risked their investment significantly.

Thoroughly vet the expertise and reputation of potential furnace suppliers. Look beyond brochures and sales presentations. Ask for:

- References: Speak to existing customers, particularly those with similar applications.

- Technical Expertise: Assess the depth of their metallurgical knowledge related to aluminum annealing. Can they discuss TTT diagrams and recrystallization kinetics11 intelligently?

- Design and Manufacturing Capabilities: Do they design and build in-house? What quality control processes are in place? (AKS, for example, integrates R&D, design, and manufacturing).

- Experience with Your Specific Alloys/Industry: Proven track record is important.

After-sales support is critically important for complex industrial equipment. Consider:

- Installation and Commissioning Support: Is it comprehensive? Is training provided?

- Availability of Spare Parts: How quickly can critical spares be obtained?

- Technical Support and Field Service: What is their response time? Do they have local or regional support? (AKS has a global service network).

- Warranty Terms: Understand what is covered and for how long.

A lower initial price can quickly be offset by poor support and extended downtime. I’ve seen companies struggle immensely when a critical furnace component fails and their supplier is unresponsive or lacks the capability for quick resolution. This is why at AKS, we emphasize our integrated technical service as a core part of our offering.

Future-Proofing: Considering Scalability, Technological Advancements, and Sustainability

When selecting an annealing furnace, think beyond your immediate needs. Consider your company's growth plans. Will your production volume increase significantly in the next 5-10 years? If so, is the furnace scalable (e.g., modular design for continuous lines where heating/cooling zones can be added) or is it better to plan for future additional units? A client producing aluminum extrusions initially needed capacity for 500 tons/month. Anticipating growth to 1000 tons/month within three years, we proposed an AKS continuous annealing line with a base configuration meeting current needs but designed with clear provisions (space, utility connections, control system capacity) for adding an identical parallel heating section later, effectively doubling capacity without requiring a completely new furnace.

Stay informed about technological advancements in annealing. Are there emerging technologies (e.g., improved burner designs, advanced sensor technology for process control, AI-driven optimization) that could benefit your operation? Choose a supplier who demonstrates a commitment to innovation and can offer upgrades or retrofits as technology evolves. For example, the integration of Industry 4.0 features like remote diagnostics, predictive maintenance, and integration with plant-wide MES (Manufacturing Execution Systems) is becoming increasingly important. Our newer AKS furnace models incorporate these capabilities.

Finally, sustainability is an increasingly critical factor. This includes:

- Energy Efficiency: As discussed, choose furnaces with high thermal efficiency and low specific energy consumption. This reduces both operational costs and carbon footprint.

- Reduced Emissions: For fuel-fired furnaces, look for low-NOx burners and compliance with environmental regulations.

- Material Efficiency: Furnaces that ensure consistent quality reduce scrap, saving material and energy.

- Longevity and Durability: A well-built furnace that lasts longer is inherently more sustainable than one that needs frequent replacement.

The table below summarizes key future-proofing considerations:

| Consideration | Key Questions to Ask | Потенциальные преимущества |

|---|---|---|

| Scalability | Can capacity be easily increased? Is the design modular? | Accommodates growth, defers large initial investment |

| Technological Adaptability | Is the control system upgradeable? Can new sensors/features be integrated? | Access to future improvements, maintains competitiveness |

| Supplier Innovation | Does the supplier invest in R&D? Do they offer retrofits for older models? | Long-term partnership, access to new tech |

| Энергоэффективность | What is the SEC? Are there heat recovery systems? Is insulation state-of-the-art? | Lower opex, reduced environmental impact |

| Emission Control | Does it meet current/future emission standards? (for fuel-fired) | Regulatory compliance, corporate responsibility |

| Durability/Lifespan | What materials are used for critical components? What is the expected operational life? | Lower TCO, reduced replacement cycle |

By carefully considering these recommendations, you can select an annealing furnace that is not just a piece of equipment, but a strategic asset that supports your aluminum strip production goals for years to come.

Pilot tests reduce investment risksПравда

Conducting pilot tests on a prospective furnace allows verification of metallurgical properties before full investment.

Lower price always means better valueЛожь

A lower initial furnace price may be offset by poor after-sales support and extended downtime costs.

Заключение

Choosing the right aluminum strip annealing furnace requires balancing production volume, alloy specifics, quality demands, and long-term efficiency. By focusing on precise temperature and atmosphere control, and evaluating total cost of ownership, you ensure optimal metallurgical results and a sound, future-proof investment for your operations.

-

Understand key metallurgical changes in aluminum during annealing that restore ductility and softness. ↩

-

Explore ASTM grain size standards and their importance for aluminum's deep drawing performance. ↩

-

Learn about N2-H2 mixes for bright annealing, preventing oxidation and improving aluminum surface quality. ↩

-

Understand causes and prevention of common defects like hydrogen embrittlement and blistering in aluminum. ↩

-

Explore solution treatment and its importance for T4 temper in 6xxx aluminum alloys. ↩

-

Explore differences, pros, and cons of catenary and flotation designs for strip support. ↩

-

Understand SEC measurement and its use for benchmarking furnace energy efficiency. ↩

-

Discover how OEE measures manufacturing productivity and identifies improvement areas. ↩

-

Learn about the ASTM standard for measuring grain size, crucial for aluminum quality control. ↩

-

Understand NADCAP requirements for aerospace suppliers, ensuring high-quality heat treatment processes. ↩

-

Discover metallurgical principles of TTT diagrams and recrystallization, key to understanding annealing. ↩