Your stainless steel products suffer from oxidation and a poor finish. This costs you money and customers. The solution is mastering the яркий отжиг[^1] process to eliminate these defects entirely.

The bright annealing process is a heat treatment that creates a clean, bright surface on metals. To achieve under 10ppm oxygen control, you need a furnace with a tightly sealed, protective atmosphere (like nitrogen and hydrogen) and precise temperature regulation to prevent any oxidation during heating and cooling.

As the General Manager of AKS, I've seen firsthand how controlling oxygen is the key to unlocking superior product quality and efficiency. It's not just a technical detail; it's a strategic advantage. In this post, I'll walk you through the five essential steps to achieve this level of precision in your own operations.

Step 1: Understanding the Basics of the Bright Annealing Process?

The term "bright annealing" can seem complex. Without a clear understanding, you can't troubleshoot production issues or select the right furnace. I'll explain the fundamental goal of this process.

Bright annealing is a heat treatment performed in a controlled atmosphere furnace. Its purpose is to soften metal and relieve internal stresses without causing surface oxidation. This results in a bright, shiny, and scale-free surface, ready for further processing or sale.

At its core, bright annealing is about restoring a metal's ductility. When you cold-work materials like stainless steel (grades 201, 304), copper, or brass, they become hard and brittle. Annealing reverses this by heating the metal to a specific temperature to recrystallize its grain structure, making it soft and workable again.

Why "Bright"?

The "bright" part is what sets this process apart. Traditional annealing happens in the open air, which causes an oxide layer, or scale, to form on the surface. This scale is dull and must be removed with costly and time-consuming processes like acid pickling. Bright annealing avoids this entirely by performing the heat treatment in an oxygen-free environment. The result is a product with a mirror-like finish straight out of the furnace.

Key Metallurgical Goals

The two main goals are stress relief and preventing oxidation. By achieving both, you produce a higher-value material. This directly impacts your market competitiveness because a clean, bright surface is a clear indicator of quality that customers can see and feel. It’s the first step to a superior final product.

Step 2: Preparing the Furnace Environment for Optimal Results?

Are you getting inconsistent annealing results despite having a running furnace? Oxygen leaks and atmospheric impurities are often the silent killers of quality. Proper furnace preparation is your first line of defense.

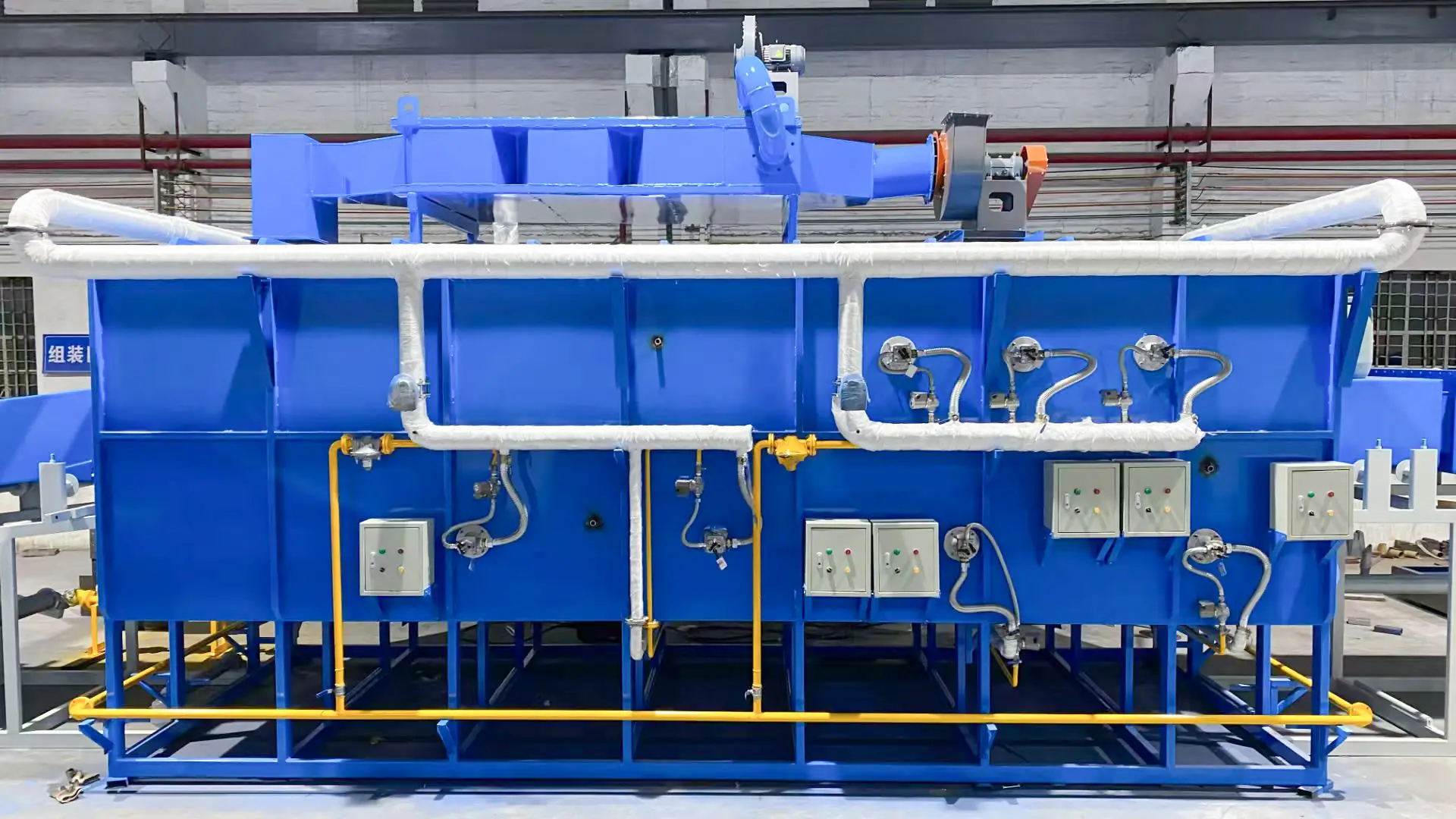

Preparing the furnace involves creating a perfectly sealed environment and purging it of all oxygen. This is done by flooding the heating chamber with a protective gas, typically a mix of nitrogen and hydrogen, to establish an inert or reducing atmosphere before the metal enters.

You can have the most advanced heating system in the world, but if your furnace leaks, you will never achieve a truly bright finish. Oxygen is the enemy of bright annealing. Even a tiny amount can cause discoloration and defects. That's why the structural integrity of the furnace is paramount. At AKS, we design our furnaces to be exceptionally well-sealed, which is a key factor in their stable, 24/7 operation and greater than 98% uptime.

The Role of Protective Atmospheres

Once the furnace is sealed, you must replace the air inside with a protective atmosphere.

- Nitrogen (N₂): This is an inert gas. It doesn't react with the metal. Its main job is to displace the oxygen.

- Водород (H₂): This is a reducing gas. It actively seeks out and reacts with any residual oxygen molecules, converting them to water vapor (H₂O), which is then purged from the furnace.

The right mixture of these gases creates an environment where oxidation is chemically impossible. This preparation step is non-negotiable for achieving that critical <10ppm oxygen level and ensuring your product quality is consistent batch after batch.

Step 3: Implementing Precise Temperature and Atmosphere Controls?

Even with a protective atmosphere, are you still seeing surface defects? Your temperature control might be the culprit. True success comes from the precise synergy of temperature and atmosphere working together.

Precise control means maintaining the annealing temperature within a very narrow window and keeping oxygen levels consistently below 10ppm. This requires advanced sensors and automated control systems that adjust gas flow and heat input in real-time to prevent fluctuations that cause oxidation.

Temperature is just as critical as the atmosphere. If the temperature is too low, the metal won't anneal properly. If it's too high or fluctuates, you risk damaging the metal's microstructure and can even promote certain types of oxidation. For C-suite leaders and plant managers, this precision is where you make your money. It's the difference between a 95% qualification rate and the 99%+ rate our clients achieve.

Why ±3℃ Matters

At AKS, our furnaces maintain a temperature accuracy[^2] of ±3℃. This level of stability is not a luxury; it's a necessity. It ensures that every inch of the metal coil receives the exact same thermal treatment. This uniformity is what guarantees consistent mechanical properties and a flawless surface finish. We achieve this through innovations like our advanced fuel/air ratio control and a dual-layer heat recovery system, which also reduces gas consumption by 10-17%.

The AKS Control System

Our integrated control system is the brain of the operation. It links the temperature sensors and oxygen sensors[^3] to the heating elements and gas valves, creating a closed-loop system that is constantly self-correcting.

| Характеристика | Стандартная топка | Печь AKS |

|---|---|---|

| Temperature Fluctuation | ±10℃ or more | ±3℃ |

| Контроль атмосферы | Manual / Basic | Automated, Real-Time |

| Product Qualification Rate | 85-95% | >99% |

| Энергоэффективность | Standard | 20-40% Lower Cost |

This level of control directly addresses the core pain points of production instability and poor product quality.

Step 4: Monitoring and Adjusting Oxygen Levels During Annealing?

You've set up the furnace perfectly, but how do you know it's staying that way? Without real-time monitoring, you're just hoping for the best and risking entire batches of product.

Continuous monitoring uses oxygen sensors placed inside the furnace to provide real-time data on atmosphere quality. If oxygen levels rise above the target (<10ppm), the control system automatically adjusts the protective gas flow to correct the imbalance, ensuring consistent quality.

"Set it and forget it" does not work in high-stakes industrial processes. A successful bright annealing run requires constant vigilance. But you can't have an engineer watching a gauge every second of the day. That's why automation is so important. Our systems are designed for stable, 24/7 operation because we build this vigilance directly into the furnace's logic. This is how we help our clients boost their annual production by over 10%.

The Critical Feedback Loop

The process is simple but powerful:

- An oxygen sensor detects a tiny increase in O₂ ppm.

- It sends a signal to the central control unit.

- The control unit instantly increases the flow of protective gas (like hydrogen) to neutralize the oxygen.

- The oxygen level drops back to the safe zone, often in a matter of seconds.

This feedback loop runs continuously, making thousands of micro-adjustments during a single run. It's what allows for our guaranteed <10ppm O₂ control. [Insert anecdote about a client's success in reducing defects] This proactive approach prevents small issues from becoming catastrophic failures that lead to downtime and scrapped material.

Step 5: Ensuring Consistent <10ppm Oxygen Control in Final Products?

The annealing run is complete. But how can you be certain you hit the <10ppm O₂ target? One bad batch can be disastrous for your bottom line. The proof is in the final product.

Ensuring consistency involves a furnace designed for controlled cooling and robust quality control. The furnace's cooling section must maintain the protective atmosphere until the metal is cool enough to not re-oxidize when exposed to air. This guarantees the bright finish is preserved.

Many people focus only on the heating phase, but the cooling phase is just as important. Hot metal is highly reactive. If you expose a stainless steel coil to air while it's still hot, it will oxidize instantly, and all your hard work will be undone. Your furnace must protect the product throughout the entire thermal cycle.

The Importance of Controlled Cooling

Our furnaces feature a precision cooling system. This section is also sealed and flooded with the same protective atmosphere as the heating section. It's designed to remove heat efficiently while preventing any contact with oxygen until the metal's temperature is well below its oxidation point. This final step locks in the bright, clean surface finish.

The Business Impact of Consistency

When your process is this controlled, the results become predictable. This is how our clients achieve monthly production capacities of over 10,000 tons with product qualification rates[^4] exceeding 99%.

| O₂ Level | Expected Surface Finish | Product Qualification Rate |

|---|---|---|

| >50ppm | Dull, visible oxide layer | <85% (Requires rework) |

| 20-50ppm | Hazy, inconsistent finish | 85-95% |

| <10ppm | Bright, mirror-like finish | >99% |

For executives and managers, this consistency is everything. It means less waste, predictable output, lower operating costs, and happier customers. It transforms your heat treatment line from a cost center into a competitive advantage.

Заключение

Achieving under 10ppm oxygen control in bright annealing isn't magic; it's engineering. It requires a furnace built for precision, stability, and control. By mastering these five steps, you can eliminate defects, boost productivity, and deliver the high-quality products that your customers demand.