Struggling with brittle, cracked steel after processing? You're chasing ductility[^1] but ending up with inconsistent quality, hurting your production line's efficiency and your bottom line. It's a frustrating trade-off.

Yes, annealing fundamentally lowers steel's tensile strength and hardness. This process is intentionally designed to relieve internal stresses, refine the grain structure, and significantly increase the material's ductility and toughness, making it easier to form and machine without fracturing.

I see this question come up a lot with clients. They worry that by making steel softer, they are compromising its integrity. But the truth is, this reduction in strength is not a flaw; it's a feature. It's the key to unlocking the material's true potential for complex applications. The real challenge isn't about preventing the strength reduction—it's about controlling it with precision. Let's dive into how this process works and how you can master it.

How Does the Annealing Process Affect the Strength of Steel?

You need workable steel, but the raw material is too hard and brittle. Pushing it through forming processes leads to defects and tool wear, slowing down your entire operation.

The annealing process affects steel's strength by heating it to a specific temperature, holding it there, and then cooling it slowly. This thermal cycle rearranges the steel's internal crystal structure, reducing dislocations and internal stresses, which results in lower hardness and tensile strength.

Let's break this down further. When steel is worked—rolled, drawn, or stamped—its grain structure becomes distorted and stressed. Think of it like a tangled ball of yarn. This state, known as закалка[^2], makes the steel stronger but also much more brittle. Annealing is the solution. By carefully applying heat, we give the atoms in the steel's crystal lattice enough energy to move around and settle into a more orderly, relaxed state. This process, called рекристаллизация[^3], creates new, stress-free grains. The result is a significant drop in hardness and tensile strength but a huge gain in ductility and toughness. It’s a strategic trade-off. We are essentially resetting the material's properties to make it suitable for further manufacturing steps. In my experience, a well-controlled anneal is the difference between a high-yield production run and a pile of scrap.

What Are the Underlying Reasons for the Reduction in Steel Strength During Annealing?

You see the final result—softer steel—but don't understand the "why." Without knowing the mechanism, it's hard to trust the process or troubleshoot when things go wrong with quality.

The reduction in steel strength is caused by microstructural changes at the atomic level. The heat from annealing eliminates crystal defects called dislocations and promotes recrystallization, where new, strain-free grains form. This more uniform and relaxed grain structure is inherently softer and more ductile.

When I talk to engineers on the factory floor, I explain it like this. Imagine a crowded room where everyone is pushing against each other (work-hardened steel). It's a very rigid, strong structure, but nobody can move. Annealing is like telling everyone to relax and take a step back.

The Role of Recrystallization

During the heating phase, the steel reaches its recrystallization temperature. At this point, new, tiny grains begin to form and grow within the old, deformed ones. These new grains are free from the internal stresses that made the steel hard and brittle. As they consume the old structure, the material's overall hardness drops dramatically.

Grain Growth and Its Effects

If we hold the steel at the annealing temperature[^4] for too long, these new grains start to merge and grow larger. While this further reduces hardness, excessively large grains can sometimes be undesirable for certain applications. This is why precise time and temperature control is not just important; it's everything. It allows us to fine-tune the final grain size to achieve the perfect balance of properties.

What Are the Potential Impacts of Reduced Steel Strength on Industrial Applications?

You're concerned that softer, less-strong steel might fail in its final application. This fear can lead to overly conservative processing, resulting in material that is difficult to work with.

While reduced strength might be a concern for final structural components, it is a critical benefit for intermediate manufacturing stages. The increased ductility allows for deep drawing, complex bending, and stamping without cracking, leading to higher product qualification rates and less material waste.

The impact of reduced strength is entirely dependent on context. It's not about "good" or "bad," but "right for the job." For a manufacturer of stainless steel sinks, for example, high ductility is paramount. They need to press a flat sheet of steel into a deep, complex shape. A work-hardened, high-strength sheet would simply crack under the strain. By annealing the steel first, they reduce its strength to a point where it can flow into the die smoothly. The final product might then be strengthened through other means if required. I recently worked with a client in the automotive stamping industry who was experiencing high failure rates. [Insert anecdote about a client's success in reducing defects]. By refining their annealing process, they dramatically improved their forming success, which directly boosted their production output by over 10%. The key takeaway is this: annealing enables manufacturing. It prepares the steel for its journey to becoming a final product.

How Can Precision Control in Annealing Optimize Steel Performance?

You know control is important, but your current equipment has wide temperature swings and poor atmosphere management. This leads to inconsistent results, oxidation, and costly rework or scrap.

Precision control over temperature and atmosphere is the key to optimizing performance. By maintaining a stable temperature (±3℃) and a pure atmosphere (<10ppm O2), you ensure uniform recrystallization and prevent surface oxidation, achieving the exact desired ductility without sacrificing surface quality.

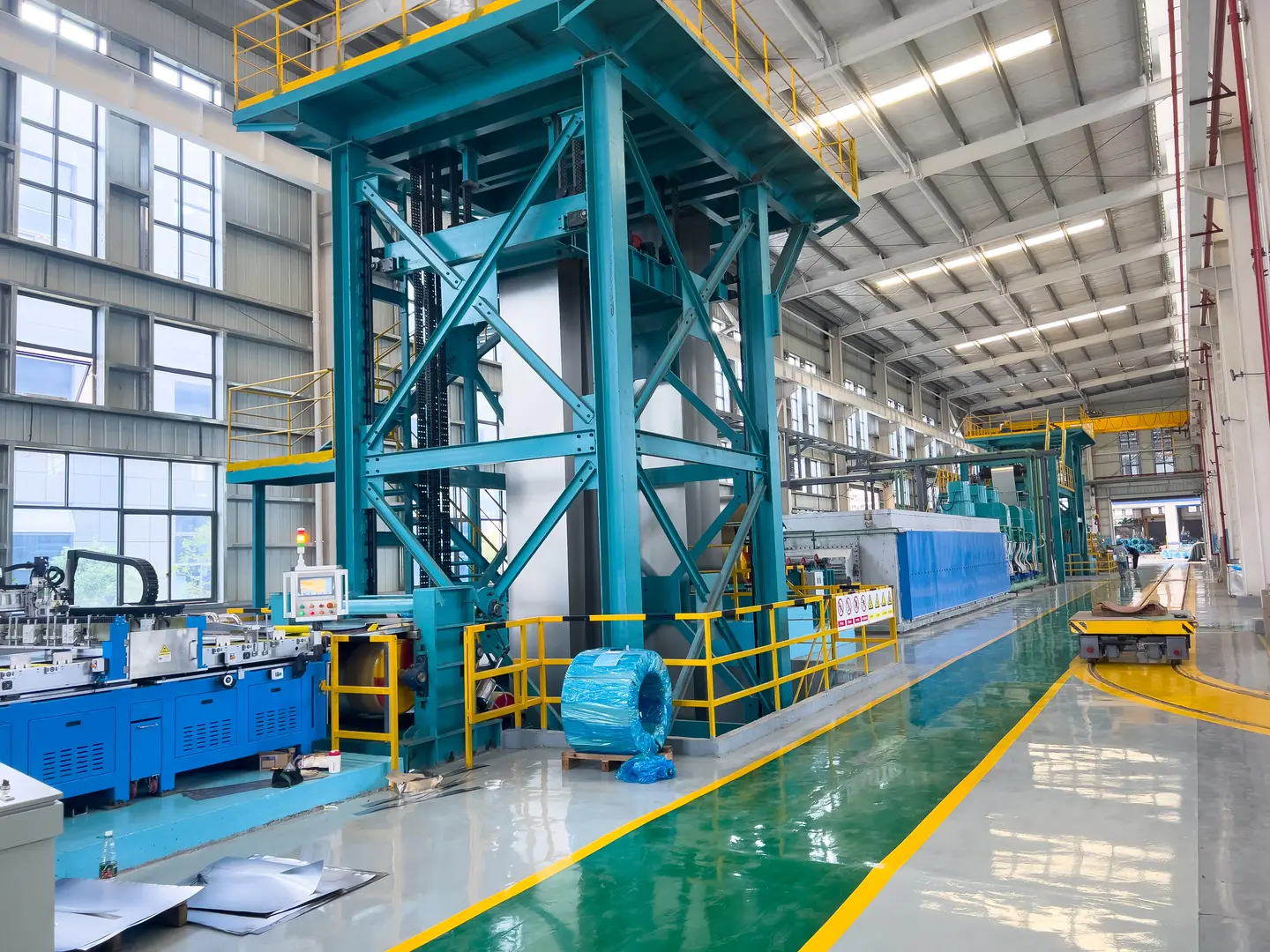

This is where advanced technology makes a world of difference. At AKS, we built our Bright Annealing Furnaces to solve this exact problem. Traditional furnaces often struggle with consistency, but modern systems offer a level of control that was previously impossible.

The Power of Data

Let's look at the hard numbers. Precise control directly translates into better business outcomes. It’s not just a technical detail; it’s a competitive advantage.

| Параметр | Стандартная топка | AKS Печь для отжига |

|---|---|---|

| Контроль температуры | ±10-15℃ | ±3℃ |

| Atmosphere Purity (O2) | >50 ppm | <10 ppm |

| Product Qualification Rate | ~95% | >99% |

| Operational Uptime | <95% | >98% |

What This Means for You

With a temperature window as tight as ±3℃, you get an incredibly uniform grain structure across the entire steel coil. And by keeping oxygen below 10 parts per million, you get a bright, clean surface that requires no post-processing like acid pickling. This precision means your product qualification rate skyrockets to over 99%. You're not just making softer steel; you're making consistently perfect steel, every single time.

What Are the Best Practices for Maintaining Strength While Annealing Steel?

You need to soften the steel enough to form it, but you want to retain as much strength as possible for the final product. How do you find that perfect balance?

The best practice is to use the lowest possible annealing temperature and the shortest time that still achieves full recrystallization. This refines the grain structure for ductility without promoting excessive grain growth, which would further reduce strength. Precision equipment is essential for this.

Mastering the annealing process is about walking a fine line. You need to relieve stress without completely eliminating the strength characteristics you might need later. Here is the approach my most successful clients follow.

Start with the End in Mind

First, clearly define the mechanical properties your final product requires. Then, work backward. This will tell you the target properties you need after annealing. Don't just anneal for maximum softness; anneal for optimal formability while preserving the necessary base strength.

Invest in a Controllable System

You cannot follow best practices with substandard equipment. To hit that precise time-temperature combination, you need a furnace that offers exceptional stability and responsiveness. Our furnaces, with their advanced fuel/air ratio controls and precision cooling systems, are designed for exactly this. They allow operators to execute a precise thermal recipe without deviation.

Monitor and Maintain

Finally, consistent results require a well-maintained system. A reliable furnace shouldn't need constant attention. We designed our equipment with long maintenance intervals of 180 days or more, ensuring you have the uptime (>98%) needed for continuous, stable production. This reliability is a cornerstone of any best practice.

Заключение

Annealing does reduce steel's strength, but this is a necessary and strategic step to improve ductility for manufacturing. The key isn't to avoid this change but to control it with absolute precision. With the right technology, you can optimize steel performance, boost product quality, and drive operational efficiency.