Struggling with inconsistent material properties from your heat treatment? This often leads to wasted resources and production delays. The key lies in correctly matching your full annealing process to your material.

Full annealing is a heat treatment process that refines a metal's microstructure by heating it above a critical point and then cooling it slowly. Optimizing this process means precisely controlling temperature and atmosphere to reliably achieve desired softness, ductility, and uniformity for superior product quality.

As a General Manager in this industry, I've seen firsthand how a well-optimized annealing process can transform a production line. It moves heat treatment from a simple cost center to a source of real competitive advantage. Let's explore how you can achieve this level of operational excellence.

Understanding the Basics: What is Full Annealing in Heat Treatment?

The term "full annealing" can seem complex. Misunderstanding it leads to process errors and subpar results. Let's break down exactly what it is and why it matters for your operations.

Full annealing is a fundamental heat treatment where a metal is heated, soaked at a specific temperature, and then cooled very slowly. This process removes internal stresses, softens the material, and refines its grain structure, making it much easier to machine or form later.

Let's dive deeper into the mechanics. The process isn't just about heating and cooling; it's a carefully controlled, three-stage procedure that fundamentally changes the metal's internal state. My team at AKS focuses on perfecting each stage because we know that precision here dictates the final product quality.

The Heating Phase

First, we heat the material to a temperature above its upper critical point. For different steels, this temperature varies. The goal is to transform the grain structure, known as the microstructure, into a uniform state called austenite[^1]. Getting this temperature exactly right is non-negotiable. A furnace with poor control can overshoot or undershoot, ruining the entire batch.

The Soaking Phase

Once at the target temperature, the material is "soaked." This means we hold it at that exact temperature for a set period. The duration depends on the material's thickness and composition. This phase ensures the heat penetrates the entire workpiece and the microstructural transformation is complete.

The Cooling Phase

This is arguably the most critical stage. The material must be cooled extremely slowly, typically by leaving it inside the furnace and letting the furnace cool down naturally. This slow cooling allows a new, refined grain structure to form, resulting in a soft, stress-free, and highly ductile material. Rushing this step is a common mistake that undermines the entire process.

Current Practices in Full Annealing and Their Impact on Material Properties?

Many facilities are still using outdated annealing equipment. This directly results in inconsistent product quality and unnecessarily high energy bills. Modern practices offer far greater control and efficiency.

Modern full annealing focuses on precise atmosphere and temperature control to achieve specific material properties. The primary goal is preventing surface oxidation while ensuring a uniform microstructure, which directly boosts product qualification rates and overall performance in downstream applications.

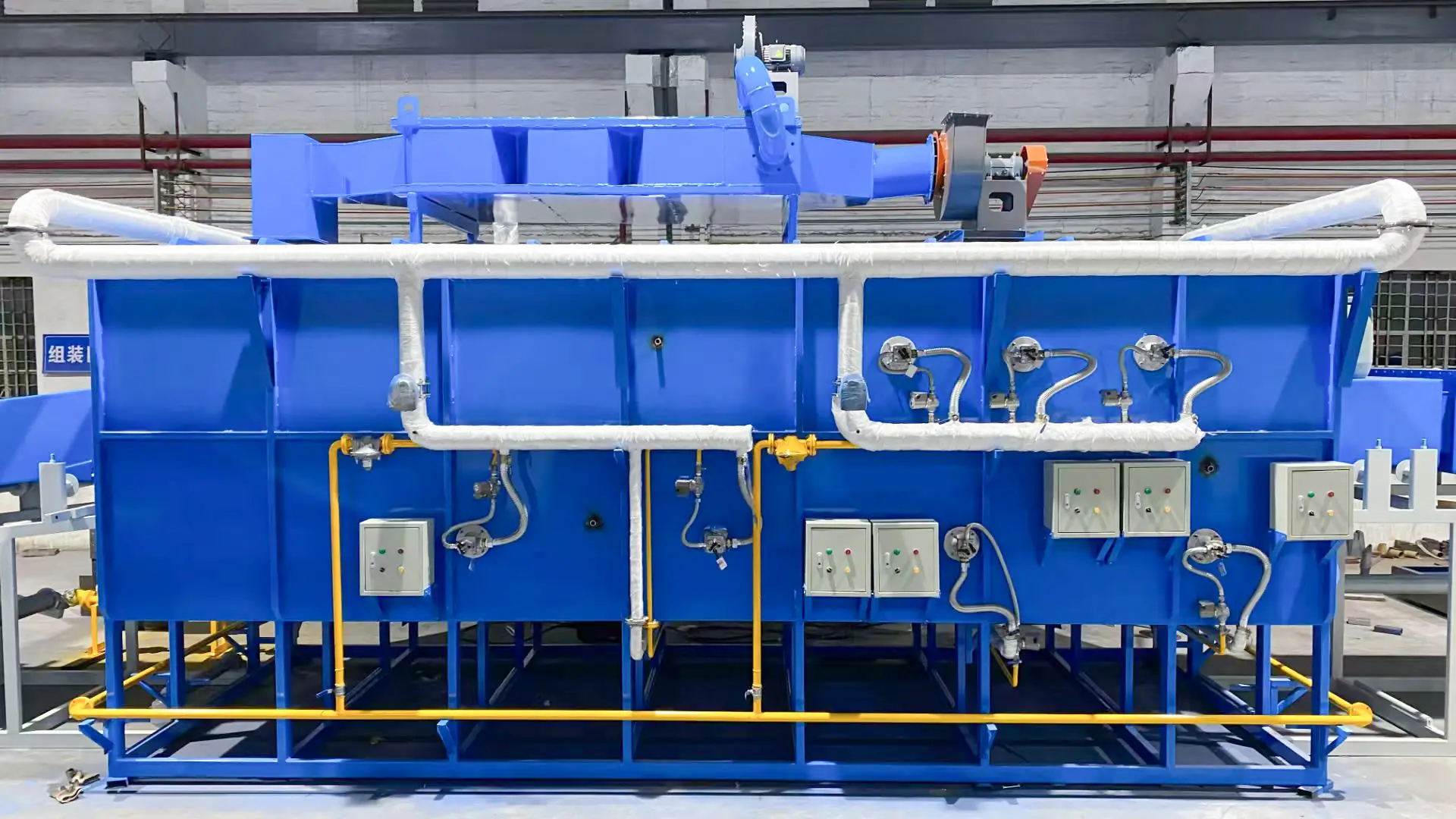

The difference between old and new methods is stark. I've visited plants where the approach is more art than science, leading to constant rework. At AKS, we believe in data-driven, repeatable processes. The impact on material properties is too significant to leave to chance. A modern furnace, like our Bright Annealing Furnace, gives you the control needed to hit your targets every single time. It's about shifting from reactive adjustments to proactive process management.

Atmosphere Control is Key

A major advancement is the ability to control the furnace atmosphere. By using gases like Nitrogen, Hydrogen, or Argon, we can create an environment with extremely low oxygen levels[^2]—my team regularly achieves under 10ppm O2. This prevents oxidation, resulting in a clean, bright surface finish that often eliminates the need for post-treatment processes like acid picking. This directly improves quality and reduces operational steps.

Energy Efficiency Drives ROI

Older furnaces are often energy hogs. They waste a tremendous amount of heat. Modern designs incorporate advanced systems to combat this. For example, our furnaces use a dual-layer heat recovery system[^3] and advanced fuel/air ratio controls. This technology allows us to cut gas consumption by 10-17% compared to competitors, directly lowering our clients' operational costs by 20-40%.

| Feature | Outdated Practice | Modern Practice (AKS) |

|---|---|---|

| Atmosphere Control | Air or uncontrolled | Precise N2/H2/Ar (<10ppm O2) |

| Temperature Control | Wide variance (±10℃+) | Precision control (±3℃) |

| Energy Use | High, no recovery | Efficient, with heat recovery |

| Surface Finish | Oxidized, requires cleaning | Bright, clean surface |

| Consistency | Low, high defect rate | High, >99% qualification rate |

What Challenges Are Faced in Matching Full Annealing Processes to Specific Materials?

Every metal alloy behaves differently under heat. Applying a one-size-fits-all annealing process is a recipe for defects, scrap, and wasted capacity. Understanding these material-specific challenges is the first step to mastering your process.

The primary challenge is tailoring the thermal cycle—heating rate, soaking time, and cooling rate—to the unique properties of each material, such as stainless steel or copper. Maintaining a pure atmosphere to prevent surface reactions and ensuring uniformity across large batches are also major hurdles.

In my experience, this is where standard, off-the-shelf equipment fails. A furnace designed for 304 stainless steel might not have the precise cooling control needed for a sensitive copper alloy. This is why over 70% of the furnaces we build at AKS are customized. We work with our clients to engineer a solution that directly addresses the specific challenges their materials present.

Material-Specific Temperature Profiles

Different alloys have different critical temperatures[^4]. Stainless steel requires a much higher annealing temperature than aluminum, for instance. Furthermore, the rate of heating and cooling must be carefully managed. A furnace must be flexible enough to execute these unique temperature "recipes" with absolute precision. Our ±3℃ temperature control is essential for this.

Atmosphere Integrity

Some materials are highly reactive. Copper, for example, can easily oxidize if the furnace atmosphere isn't pure. Maintaining an inert or reducing atmosphere with less than 10ppm of oxygen is critical. Any leak or contamination can ruin the surface finish of an entire production run, a costly mistake.

Scalability and Consistency

What works for a small test piece in a lab must also work for a 10-ton coil on the factory floor. Ensuring that the temperature and atmosphere are uniform throughout a massive furnace chamber is a significant engineering challenge. Without it, you get inconsistent properties within the same batch, leading to quality control nightmares.

What Are the Strategic Approaches to Overcome Full Annealing Process Matching Issues?

Process matching issues can seem overwhelming. They can stall production, inflate costs, and damage your reputation. But with a clear strategy, you can overcome these challenges and turn your heat treatment into a strength.

A successful strategy involves three core elements: investing in flexible, high-precision equipment; implementing robust data monitoring and process control; and building a strong partnership with a knowledgeable equipment supplier who provides ongoing technical support and expertise.

Thinking strategically means looking beyond the initial purchase price of a furnace. It means evaluating the total cost of ownership and the equipment's ability to adapt to future needs. The right approach transforms your heat treatment operation from a source of problems into a reliable engine for growth.

Invest in Modern, Controllable Technology

The foundation of any good strategy is having the right tools. You cannot achieve precision control with outdated equipment. Investing in a furnace with advanced sensors, superior insulation, and sophisticated atmosphere management systems provides the capability you need to execute complex annealing cycles perfectly. This technology is the bedrock of consistency.

Prioritize Data and Process Control

You cannot control what you cannot measure. A modern annealing line should provide real-time data on temperature, atmosphere composition, and line speed. This data allows your engineers to validate that the process is running to spec and to make informed adjustments. It creates a feedback loop that drives continuous improvement and ensures every batch meets your quality standards.

Foster a Partnership Mindset

Your furnace supplier should be more than just a vendor; they should be a technical partner. At AKS, we see our role as providing integrated solutions, from R&D and design to installation and ongoing technical service. We help our clients develop the right annealing recipes for their materials. [Insert anecdote about a client's success in reducing defects]. This collaborative approach ensures you get the most out of your investment.

What Are the Technical Recommendations for Optimizing Full Annealing in Industrial Applications?

You need actionable technical advice to make real improvements. Without it, you are just guessing. Here are the concrete technical systems my team at AKS recommends focusing on to truly optimize your operations.

For industrial optimization, we recommend three technical pillars: an advanced atmosphere control system to keep oxygen below 10ppm, a dual-layer heat recovery system to cut energy costs by 20-40%, and a precision cooling system to ensure proper microstructure formation. These deliver quality, efficiency, and reliability.

These recommendations are not theoretical. They are based on the core technologies we have developed and implemented in our Bright Annealing Furnaces. These systems work together to solve the most common pain points in heat treatment: poor quality, high energy consumption, and frequent downtime. By focusing on these technical areas, you can build a highly efficient and stable production process.

Advanced Fuel/Air Ratio Control

For gas-fired furnaces, precise combustion is critical for both temperature stability and energy efficiency. Our advanced control systems continuously adjust the fuel-to-air mixture[^5]. This ensures complete combustion, maximizes heat transfer to the product, and is a key reason we can reduce gas consumption so significantly.

Precision Cooling Systems

The cooling phase is just as important as the heating phase. The rate of cooling determines the final grain structure and mechanical properties. Our precision cooling systems[^6] allow for highly controlled and adjustable cooling profiles, enabling you to hit the exact specifications required for different materials, from rapid cooling for some alloys to extremely slow cooling for others.

Robust Furnace Design for High Uptime

Technical systems are useless if the furnace is always down for repairs. We design our equipment for long-term industrial use, with a maintenance interval[^7] of 180 days or more. This robust construction, combined with stable process control, results in over 98% uptime, allowing our clients to run 24/7 and boost their annual production by 10% or more.

| Technical System | Key Metric | Business Impact |

|---|---|---|

| Atmosphere Control | <10ppm O2 | >99% product qualification rate |

| Heat Recovery | 20-40% energy savings | Lower operational costs |

| Furnace Stability | >98% Uptime | 10%+ boost in annual production |

Conclusion

Full annealing is a critical process that dictates final material quality. Optimizing the match between process and material requires precise control over temperature and atmosphere. Investing in modern equipment like our AKS furnaces transforms this operational step into a powerful competitive advantage, boosting quality, cutting costs, and increasing output.