Struggling with high operating costs and inconsistent product quality? You see the potential of a new furnace but worry it’s just another major expense. The right furnace is a profit center.

A modern bright annealing furnace is worth the investment because it directly cuts energy costs by 20-40% and boosts annual production by over 10%. This combination of savings and increased output delivers a powerful and rapid return on investment, turning a cost center into a profit generator.

In my years in this industry, I've seen many plant managers focus only on the purchase price of equipment. But the real value isn't in the machine itself. It's in what the machine does for your bottom line every single day. Let's break down how the right furnace technology generates real, measurable value that far exceeds its operating cost.

Why is the bright annealing furnace considered a valuable investment in industrial production?

You need to justify large capital spending to your board. You're not sure if the promised ROI is real or just a sales pitch. A high-performance furnace is a strategic asset.

It's a valuable investment because it directly increases profitability. It achieves this by lowering energy costs, improving product qualification rates to over 99%, and ensuring stable, high-volume production that you can count on month after month.

From Cost Center to Strategic Asset

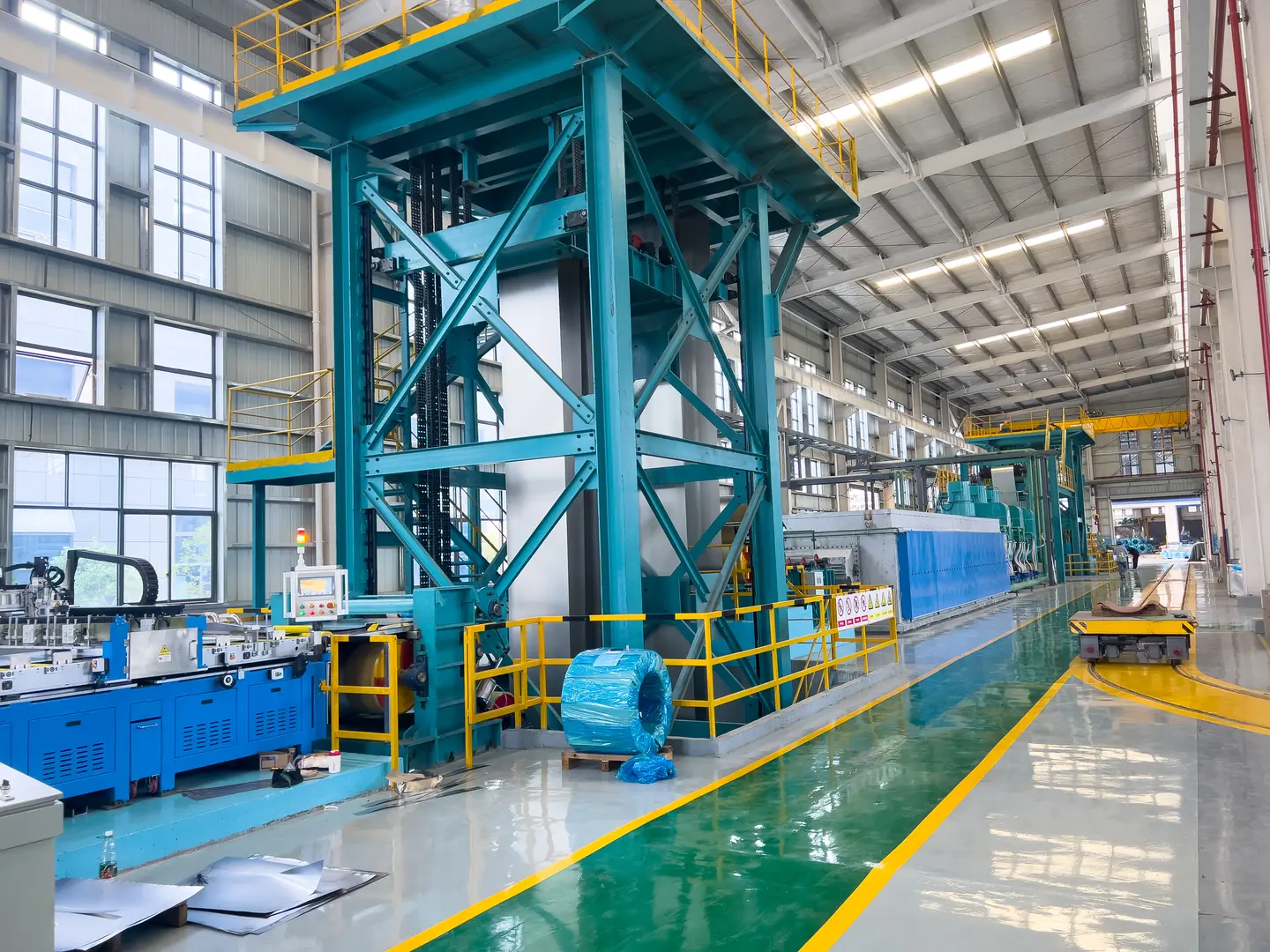

For too long, many in our industry have viewed furnaces as a necessary cost. My team and I at AKS see it differently. We design equipment to be a strategic asset that actively generates revenue. The value isn't just in heating metal; it's in the consistent, high-quality output that builds your company's reputation and market share. When your furnace delivers a product qualification rate over 99%, you virtually eliminate waste and rework costs. This has a direct, positive impact on your profit margin. Furthermore, when your furnace can reliably produce 10,000 tons or more per month with over 98% uptime, you can confidently take on larger orders and meet tight deadlines. This reliability boosts your annual production capacity by at least 10%. It transforms the production floor from a source of uncertainty into a predictable, powerful engine for growth.

What factors contribute to the high cost of operating a bright annealing furnace?

Your energy bills are climbing every month. You see furnace downtime and product defects eating into your profits. These ongoing operational costs are a major headache that never seems to end.

The highest operating costs come from two main areas. First is massive energy consumption from inefficient heating and heat loss. Second is lost revenue from production instability, frequent downtime for repairs, and rejected products that must be scrapped or reworked.

Pinpointing the Real Cost Drivers

When we analyze a client's old equipment, the cost drivers are always the same. It's not just about the gas or electricity bill. The true cost is a combination of inefficiency and unreliability. We break it down into three core areas. First is energy waste. Older designs lack modern heat recovery and precise combustion control, leading to huge energy losses. Second is production downtime. A furnace that requires frequent maintenance or breaks down unexpectedly brings your entire line to a halt, costing you thousands in lost output. Third is poor quality. Inconsistent heating and atmosphere control lead to oxidation and defects, resulting in a high rejection rate. These rejected coils represent wasted material, wasted energy, and wasted labor.

| Cost Driver | Typical Impact on Operations | AKS Solution |

|---|---|---|

| Energy Waste | 20-40% higher energy bills | Dual-layer heat recovery & advanced fuel/air control |

| Production Downtime | Unplanned stops, frequent maintenance | >98% uptime, maintenance interval ≥180 days |

| Product Rejection | High scrap rates, customer complaints | >99% qualification rate with precise controls |

How does a bright annealing furnace improve production efficiency and product quality?

You're dealing with inconsistent output and high defect rates. This hurts your reputation with customers and damages your bottom line. You need a reliable process that delivers perfect results every time.

A modern furnace improves efficiency with over 98% uptime for stable 24/7 operation. It enhances quality with precise temperature control (±3℃) and atmosphere control (less than 10ppm oxygen), which is key to preventing oxidation and ensuring a flawless bright finish.

The Technology Behind Top-Tier Performance

The secret to achieving both efficiency and quality lies in advanced control systems. At AKS, we've focused our R&D on three critical innovations. First, our advanced fuel/air ratio control system ensures complete combustion, using 10-17% less gas than competing models while maintaining exact temperatures. Second, our dual-layer heat recovery system[^1] captures waste heat from the exhaust flue and the cooling muffle to preheat combustion air and the steel strip itself. This drastically reduces the energy needed to reach the annealing temperature. Third, our precision cooling system and atmosphere control work together to cool the metal without any risk of oxidation, delivering that perfect, mirror-like "bright" finish. This combination of technologies is why our clients achieve product qualification rates above 99%. [Insert anecdote about a client's success in reducing defects]. It’s not magic; it’s just better engineering.

What solutions does the bright annealing furnace offer to common production challenges?

Standard, off-the-shelf equipment doesn't fit your specific process. You're fighting constant production instability and high energy bills. You need a solution that is tailored to your factory's unique needs.

It solves these challenges by offering deep customization for your specific needs—over 70% of our orders are customized. It also ensures stable 24/7 operation and cuts gas consumption by 10-17% through superior energy-efficient design, tackling the biggest pain points head-on.

A Direct Answer to Your Biggest Problems

We designed our bright annealing furnaces by listening to plant managers. They told us their biggest problems, and we engineered the solutions.

High Energy Consumption

The most common complaint is the cost of gas and electricity. Our solution is a multi-faceted approach to energy efficiency. The dual-layer heat recovery system I mentioned is a big part of it. This system alone can lower overall energy costs by 20-40%. It’s a simple concept: stop wasting heat and put it back to work.

Production Instability and Downtime

You can't make money when your line isn't running. Our furnaces are built for industrial reality. They are designed for stable, 24/7 operation with greater than 98% uptime. We also extended the maintenance interval to 180 days or more. This means fewer planned stops and almost no unplanned ones.

Poor Product Quality

Oxidation and inconsistent annealing are quality killers. Our solution is absolute precision. By maintaining temperature stability within ±3℃ and an oxygen-pure atmosphere[^2] below 10ppm, we eliminate the root causes of defects. This delivers a consistent, high-value product coil after coil.

What are the best practices for maximizing the return on investment of a bright annealing furnace?

You've made the investment, but how do you get the most out of it? You worry about leaving money on the table through improper use. Following a few best practices ensures maximum ROI.

To maximize your ROI, focus on three things: ensure your operators are fully trained on the new controls, stick to a simple preventative maintenance schedule, and use the furnace's reliable output data to better plan your entire production flow.

Unlocking Full Potential

Buying a great furnace is the first step. Getting the maximum value from it requires a simple, disciplined approach. First, invest in training. While our systems are user-friendly, proper training ensures your team can leverage all the advanced features for optimal efficiency. Second, embrace preventative maintenance. Our furnaces are designed for long service intervals of 180 days or more, but sticking to that schedule is critical. A few hours of planned maintenance twice a year prevents costly unplanned downtime. Third, leverage the furnace's stability for better planning. Because you can rely on its consistent output and >98% uptime, your production planners can schedule jobs more tightly and promise delivery dates with confidence. This stability ripples through your entire operation, reducing bottlenecks and improving overall plant efficiency. It’s not just about running the furnace well; it’s about integrating its reliability into your entire business strategy.

Conclusion

A bright annealing furnace is more than a piece of equipment; it's a strategic investment in your plant's profitability. By drastically cutting energy costs, virtually eliminating product defects, and providing rock-solid operational stability, it delivers a return that makes the monthly cost seem small by comparison.