Struggling to justify the cost of a new industrial furnace? The high sticker price is intimidating, but focusing on it alone can lead to expensive, long-term problems.

The true cost of an industrial annealing furnace is its Total Cost of Ownership (TCO), which includes the initial purchase price plus long-term operational costs. Key factors are energy consumption, maintenance needs, production uptime, and product quality rates, which ultimately determine the furnace's real-world ROI.

When my team and I talk with production managers, the conversation often starts with the purchase price. But the smartest operators know that the initial investment is just the beginning of the story. The real financial impact of a furnace is revealed over years of operation. In this guide, I'll break down the factors you must consider to make a truly profitable investment.

What Are the Key Cost Factors of an Industrial Annealing Furnace?

You are comparing quotes from different furnace suppliers. But if you only look at the upfront price, you risk choosing a machine that will bleed your profits through high operational costs for years. Let's look at the complete picture.

The key cost factors for an industrial annealing furnace are the initial capital expense (CapEx) and the ongoing operational expenses (OpEx). OpEx includes energy consumption, maintenance frequency, production downtime, and final product qualification rates. These operational costs often dwarf the initial investment over the furnace's lifespan.

At AKS, we encourage our clients to think in terms of Total Cost of Ownership (TCO). It’s a simple concept that provides a complete view of your investment.

Upfront Cost (CapEx)

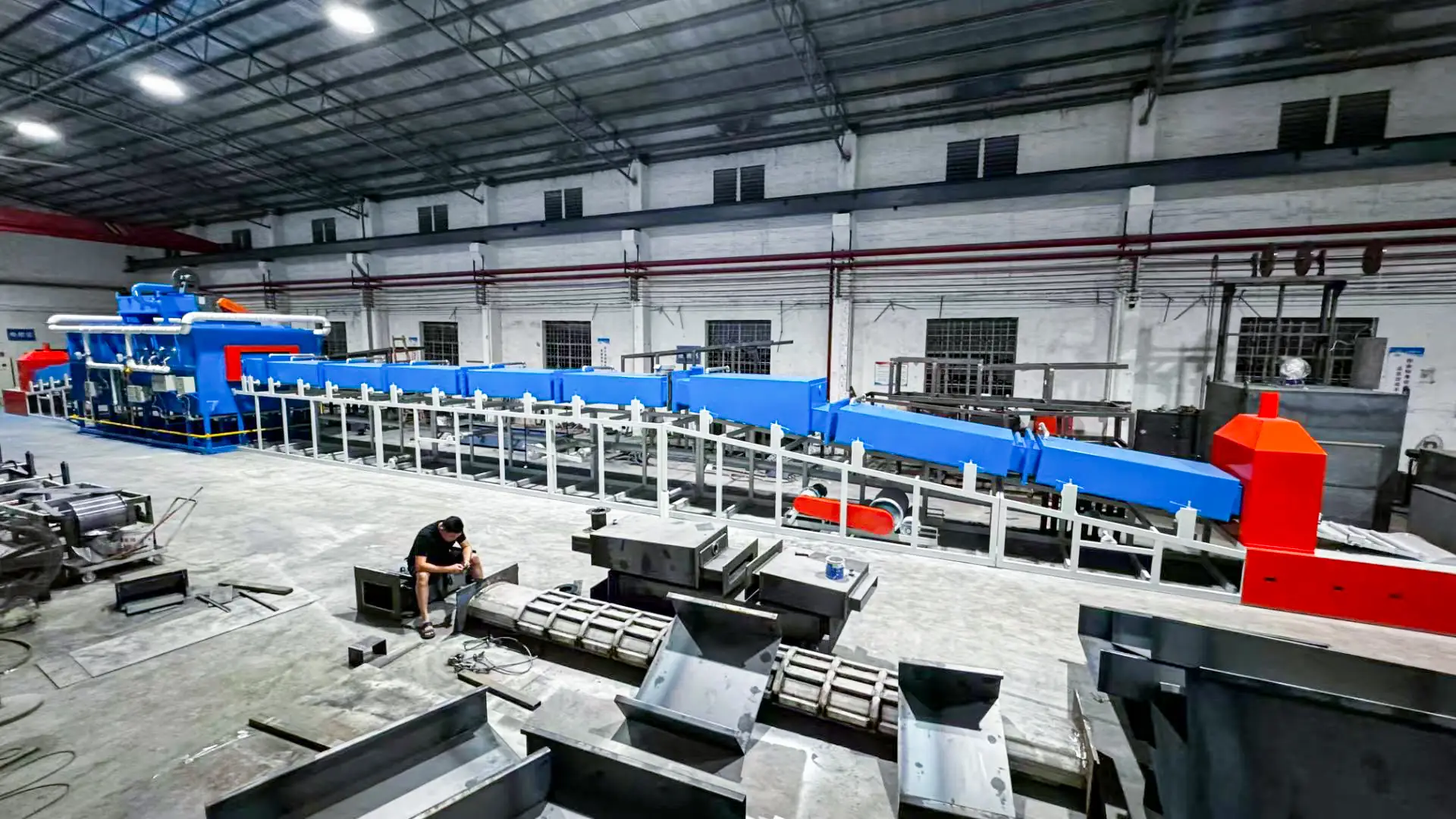

This is the most obvious cost: the price of the furnace itself, plus shipping, installation, and commissioning. It's also where customization comes in. A standard, off-the-shelf furnace might seem cheaper, but if it doesn't perfectly match your process, you lose efficiency from day one. That's why over 70% of the furnaces we build are customized. We adapt the design to fit the client's specific material, capacity, and factory layout to ensure maximum performance.

Operating Cost (OpEx)

This is where the real costs—and savings—are found. It’s what you pay every day to run the machine. We can break it down into a few critical areas. A high-performance furnace directly impacts each one.

| Cost Factor | Standard Furnace | AKS Bright Annealing Furnace |

|---|---|---|

| Energy Use | High and variable | 20-40% lower energy costs |

| Maintenance | Frequent, often unplanned | Scheduled; interval ≥180 days |

| Uptime | Unpredictable; <90% | Stable and reliable; >98% |

| Product Quality | Inconsistent; high reject rate | Consistently high; >99% qualification |

As you can see, a lower initial price can be quickly erased by higher energy bills, frequent downtime, and a high rate of rejected products.

How Does Energy Efficiency Impact the Overall Cost of an Annealing Furnace?

Your monthly energy bills are a major line item. An inefficient furnace is like a hole in your pocket, constantly draining your operational budget and hurting your profitability. The right technology plugs that hole for good.

Energy efficiency directly lowers the total cost of an annealing furnace by reducing daily operational expenses. A furnace engineered for efficiency uses significantly less gas and electricity, leading to massive long-term savings that can easily surpass any difference in the initial purchase price.

When we founded AKS, our primary goal was to tackle the biggest pain point for our customers: high energy consumption. We knew that if we could build a more efficient furnace, we could give our clients a powerful competitive advantage. The result is a design that reduces overall energy costs by 20-40% compared to many older systems. We achieve this through two key innovations.

Advanced Fuel/Air Ratio Control

First, we perfected the combustion system. Many furnaces operate with an imperfect fuel-to-air ratio[^1]. This means fuel is wasted, and combustion is incomplete, which can also harm product quality. Our system uses precise controls to maintain the optimal ratio at all times. This alone allows our furnaces to consume 10-17% less gas than many competing models to produce the same tonnage. It’s a simple change in engineering that delivers a direct, measurable saving on every ton of metal you process.

Dual-Layer Heat Recovery

Second, we don't let heat go to waste. In a typical furnace, a huge amount of thermal energy is lost in the exhaust gas and the cooling section. Our design captures this waste heat. We use a dual-layer heat recovery system[^2] to redirect that energy and use it to preheat the combustion air. This means the furnace doesn't have to work as hard or burn as much fuel to reach and maintain the target temperature. This system is a core reason our clients see such a dramatic reduction in their gas bills.

What Is the ROI for Investing in an Energy-Efficient Annealing Furnace?

You see the higher price tag on a high-efficiency furnace and hesitate. You need to prove to your management team that the extra upfront investment is a smart business decision, not a risk. Let's run the numbers.

The Return on Investment (ROI) for an energy-efficient furnace comes from adding up all the savings it generates—lower energy bills, more output from less downtime, and revenue from fewer rejected products—and comparing that to the initial investment. A premium furnace delivers a powerful ROI much faster than you might think.

Calculating the exact ROI requires a detailed analysis of your specific operation, but I can give you a clear framework based on what our clients experience. The "Return" in ROI comes from three main sources.

Calculating Your Savings

First is direct cost savings. With our furnaces, this means a 20-40% reduction in energy costs. Second is increased revenue from higher productivity. Our furnaces are built for stable, 24/7 operation with over 98% uptime, boosting annual production by 10% or more. Third is revenue protection. By maintaining a precise atmosphere with oxygen levels below 10ppm, our furnaces achieve a product qualification rate over 99%. This means you aren't wasting money and material on products you can't sell.

A Real-World Example

[Insert anecdote about a client's success in reducing defects]. I remember a client in the stainless steel coil industry who was struggling with surface oxidation, leading to a rejection rate of nearly 8%. After installing one of our bright annealing lines, their qualification rate jumped to over 99%. The money they saved by not having to scrap or re-process that material paid for a significant portion of the furnace investment within the first year alone. This is what a technology-driven ROI looks like in practice.

What Measures Can Be Taken to Optimize Energy Savings in Annealing Operations?

You already have a furnace, but your energy bills are still too high. You suspect there's room for improvement, but you're not sure where to start. Every bit of wasted energy is profit you could be keeping.

To optimize energy savings, focus on three areas: furnace technology, operational discipline, and preventative maintenance. Invest in equipment with modern heat recovery systems, ensure precise process control to avoid rework, and perform regular maintenance to keep the system running at peak efficiency.

Whether you are buying a new furnace or trying to get more from your existing one, the principles of energy optimization are the same. It's about getting the most out of every unit of energy you put in.

Invest in Modern Technology

The single biggest impact comes from the furnace's core design. If your equipment is old, it likely lacks modern efficiency features. For example, our dual-layer heat recovery system is a fundamental part of our design that drastically cuts fuel use. Similarly, a precision cooling system ensures the product exits at the right temperature without wasting excess energy. If your current furnace bleeds heat, it's bleeding money.

Maintain Operational Discipline

Efficiency isn't just about equipment; it's also about process. Running a furnace requires precise control. Our systems maintain temperature stability within ±3℃ and atmosphere purity with under 10ppm of oxygen. This consistency prevents the need for rework, which is a huge waste of energy, time, and labor. Furthermore, designing for stable, 24/7 operation, as we do, ensures the furnace runs in its most efficient state without costly and energy-intensive shutdowns and startups.

Follow a Strict Maintenance Schedule

A furnace is like any industrial machine: it needs care. Worn-out seals let in oxygen and let out heat. Dirty burners lead to inefficient combustion. Faulty sensors give bad readings, causing the control system to waste energy. We design our furnaces for long maintenance intervals of 180 days or more, but regular checks are still critical for any operation to ensure the equipment continues to perform as designed.

What Are the Best Practices for Maximizing ROI in an Industrial Annealing Furnace Investment?

You're ready to make an investment in a new annealing furnace. You want to make sure you get the best possible financial outcome for your company. A bad decision can lock you into high costs for a decade or more.

To maximize ROI, you must look beyond the initial purchase price and evaluate the furnace's Total Cost of Ownership (TCO). Prioritize equipment with proven energy efficiency, documented high uptime rates of over 98%, and precise process control. Most importantly, partner with a manufacturer who provides deep technical support.

After years in this industry, I've seen companies make great investments and poor ones. The successful ones always follow a few best practices. They treat the purchase not as a simple transaction, but as a long-term strategic decision.

Focus on TCO, Not Price

I can't say this enough. The purchase price is only one piece of the puzzle. You must ask suppliers for data on energy consumption, expected uptime, and maintenance requirements. Run the numbers for a five or ten-year period. A furnace that costs 20% more upfront but saves you 30% on energy every year is the clear winner. The math is simple, but it requires you to ask the right questions.

Prioritize Stability and Quality

Your furnace's job is to produce a high-quality product, consistently. Every hour of downtime is lost revenue. Every rejected coil is a direct loss. That's why we focused on achieving >98% uptime and a >99% product qualification rate. A furnace that runs reliably and produces a perfect product every time—with a capacity of over 10,000 tons per month like ours can—directly boosts your revenue. This is a critical part of the 'Return' in ROI.

Choose a Partner, Not Just a Supplier

Finally, choose a manufacturer who will work with you. A one-size-fits-all furnace will never be as efficient as one tailored to your needs. Because over 70% of our orders are customized, my team has become expert at understanding a client's specific challenges and engineering a solution for them. A true partner provides integrated R&D, design, and technical service to ensure your investment pays off for years to come.

Conclusion

When evaluating an industrial annealing furnace, the sticker price is just the starting point. The real measure of a good investment is its Total Cost of Ownership. By prioritizing energy efficiency, operational stability, and product quality, you can secure a powerful ROI that lowers costs and drives revenue.