Struggling with surface defects and discoloration on your annealed products? These quality issues lead to high rejection rates, hurting your bottom line and reputation. What if you could eliminate oxidation completely?

Gas purity is absolutely critical in bright annealing. It prevents surface oxidation by creating an oxygen-free environment. Controlling oxygen content below 10 ppm ensures a flawless, mirror-like finish, boosts product qualification rates above 99%, and directly protects your profitability. This is what we guarantee at AKS.

This might sound simple, but achieving it consistently is a major engineering challenge. As the General Manager of AKS, I've seen countless manufacturers struggle with this exact problem. In this post, I'll break down why gas purity is non-negotiable and how my team has engineered a solution that delivers tangible business results.

What role does gas purity play in the bright annealing process?

Your annealing process should soften metal, not tarnish it. But impure protective gas[^1] can create defects and force costly rework. Understanding the fundamental role of gas purity is the first step.

A pure protective gas, like hydrogen or a nitrogen-hydrogen mix, creates a chemically inert, oxygen-free atmosphere inside the furnace. This barrier prevents the hot metal surface from reacting with oxygen, which would cause scaling and discoloration, ensuring a "bright," clean finish right out of the furnace.

Let's dive deeper into the science and its impact. When you heat metals like stainless steel or copper to annealing temperatures, they become highly reactive. If any oxygen is present, it will immediately bond with the metal surface, forming an oxide layer. This is the discoloration and scaling you see on poorly annealed products. The entire purpose of a "bright" annealing furnace is to prevent this from happening.

The Science of a Protective Atmosphere

The protective gas serves one primary function: to displace all the oxygen from the furnace's heating chamber, known as the muffle[^2]. By filling the muffle with a pure, inert, or reducing gas, we create an environment where oxidation simply cannot occur. For materials like 304 and 201 stainless steel, this is the only way to achieve that signature bright, reflective surface that commands a premium in the market. The gas acts as a shield, protecting the metal during its most vulnerable, high-temperature state.

Impact on Material Properties

Beyond just aesthetics, this process ensures consistency. An uncontrolled atmosphere can lead to inconsistent surface properties, which can affect downstream processes like coating or plating. By maintaining a pure atmosphere, we ensure that every inch of the coil or tube has the same surface quality and the same mechanical properties. This level of consistency is what allows our clients to achieve product qualification rates of over 99%.

How does oxygen content affect the quality of annealed products?

Are you seeing dull spots or a hazy finish on your final products? This isn't just a minor cosmetic issue; it's a direct cause of customer rejections and wasted material.

Even tiny amounts of oxygen, measured in parts per million (ppm), will cause surface oxidation. This results in a dull or discolored finish instead of a truly bright one. This quality drop directly lowers product value and leads to rejections. At AKS, we target under 10 ppm O2 to solve this.

The link between oxygen content and final product quality is direct and unforgiving. I want to show you exactly what this means for your business. For the C-suite executives and production managers I speak with, this is where the technical details translate into financial outcomes. A flawless surface finish isn't just a point of pride; it's a competitive necessity that protects your margins. I remember a client who was struggling with a 5% rejection rate due to surface inconsistencies. [Insert anecdote about a client's success in reducing defects]. By focusing on gas purity, we helped them virtually eliminate that loss.

From Flawless to Flawed: The Oxygen Threshold

The difference between a premium product and a rejected one can be just a few parts per million of oxygen. The effect is not linear; it's a cliff. Once you cross a certain threshold, quality drops dramatically.

| Oxygen Content (ppm) | Surface Finish Quality | Business Impact |

|---|---|---|

| > 500 ppm | Heavy scaling, dark discoloration | High rejection rate, material scrap |

| 50 - 100 ppm | Noticeable dullness, inconsistent finish | Lower product value, customer complaints |

| < 10 ppm (AKS) | Bright, mirror-like, perfectly uniform | >99% qualification, premium price |

As you can see, maintaining oxygen levels below 10 ppm is not just a technical goal. It is a business strategy. It's how you move from fighting quality issues to leading the market with superior products.

What challenges are faced in maintaining gas purity during bright annealing?

So, you're feeding high-purity gas into your furnace, but you're still getting oxidation. This is a frustrating and common problem. Leaks and hidden impurities can sabotage your entire process.

The main challenges are preventing air from leaking into the furnace muffle, ensuring the protective gas source is truly pure, and completely purging all residual oxygen before heating begins. Even a pinhole-sized leak in a seal or weld can introduce enough oxygen to ruin an entire batch.

In my experience, solving these challenges is what separates average furnaces from high-performance industrial assets. It’s not just about what you put in; it’s about the integrity of the system that contains it. Many standard furnaces fail here because they aren't designed with absolute purity as the number one priority.

The Enemy: Air Infiltration

The biggest enemy is the outside air. A furnace operates at extreme temperatures, causing materials to expand and contract. This puts immense stress on welds, seals, and flange connections. If the furnace muffle is not perfectly designed and constructed, tiny gaps can open up, allowing oxygen to be sucked inside. This is why we at AKS insist on a fully welded muffle design and meticulous quality control on every seal. It’s about building a fortress against oxygen.

The Source: Gas Supply Integrity

The second challenge is the gas itself. You might be paying for 99.999% pure gas, but are you getting that purity inside the furnace? Contamination can happen in the supply lines. More importantly, if your furnace uses a gas generator, its efficiency and purity can fluctuate. That's why direct, real-time measurement of the atmosphere inside the furnace is essential. You cannot simply trust the label on the gas tank.

The Process: Purging and Operation

Finally, you have to get the oxygen out before you start. Before the heating cycle begins, the furnace muffle must be thoroughly purged with the protective gas to flush out all the air that was inside. An incomplete purge is a guaranteed way to produce an oxidized product. This is why automated, timed purge cycles are a critical feature for consistent quality.

How does AKS ensure zero-oxygen content in its bright annealing processes?

Achieving and holding near-zero oxygen levels consistently seems impossible for many. Standard furnaces often make this promise, but they fail to deliver it during demanding 24/7 operation.

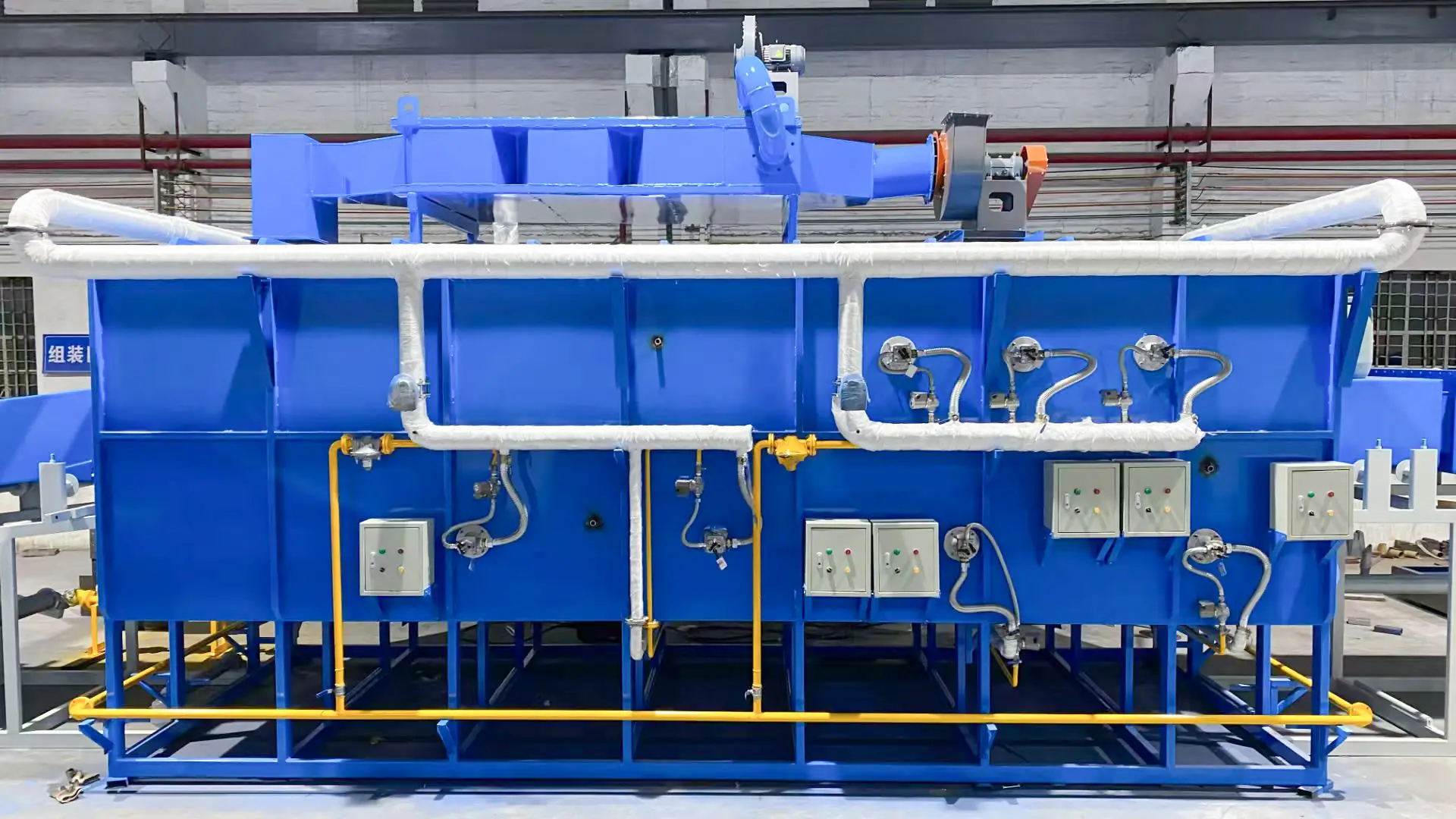

At AKS, we guarantee oxygen content below 10 ppm through our integrated design philosophy. This combines a fully welded, leak-proof muffle with an advanced atmosphere control system. This system uses real-time sensors and automated gas flow management to maintain positive pressure, actively preventing any air from entering.

This isn't a single feature; it's the result of designing the entire furnace around one core principle: absolute atmospheric integrity. When we started AKS in 2021, my team and I knew we had to solve this problem to offer a real advantage to our clients. We address it with a three-pronged approach.

Design for Purity

It starts with the physical construction. Our furnace muffles are made from high-temperature-resistant alloys and are fully welded, minimizing the use of mechanical seals that can fail over time. We pressure-test every muffle to ensure it is 100% leak-proof before it ever leaves our facility. This robust design is the foundation of our guarantee and contributes to the furnace's long maintenance intervals of 180 days or more.

Technology for Control

Next, we use technology to maintain that purity. Our furnaces are equipped with high-precision oxygen sensors that continuously monitor the atmosphere inside the muffle. This data feeds into our PLC control system, which automatically adjusts the flow of protective gas. If the system detects a potential pressure drop, it increases gas flow to maintain positive pressure, making it physically impossible for outside air to infiltrate. This is key to our >98% operational uptime.

The AKS Difference: Integrated Systems

Finally, we ensure all systems work in harmony. Our advanced fuel/air ratio control for heating and our precision cooling system create a highly stable thermal environment. This stability prevents the pressure fluctuations that can compromise atmospheric purity in other furnaces. It's this integration of thermal and atmospheric control that allows us to deliver on our promise of <10 ppm O2, 24/7.

What are the best practices for maintaining high gas purity in industrial furnaces?

You've invested in a great furnace, but poor operational practices can still compromise your results. Following a simple, disciplined checklist is the key to unlocking consistent, high-quality production day after day.

Best practices include regular leak detection, using certified high-purity gas, implementing a strict pre-process purging protocol, and continuously monitoring oxygen levels with calibrated sensors. Proactive maintenance on all seals and connections is also crucial for reliable, long-term performance.

My team doesn't just deliver a furnace; we provide the knowledge to run it at peak performance. These are the same best practices used by our most successful clients, who consistently achieve monthly capacities of over 10,000 tons with near-perfect quality.

Your Daily Purity Checklist

Think of this as your pre-flight check for every production run.

- Verify Gas Source: Check the certificate of analysis for your gas supply and ensure all line filters are clean.

- Perform Leak Test: Before starting, perform a pressure decay test to confirm the muffle's integrity. Our systems can automate this.

- Execute Full Purge Cycle: Never shorten the pre-programmed purge cycle. This step is critical for removing all residual oxygen.

- Monitor O2 in Real-Time: Keep an eye on the oxygen sensor readout throughout the process. It's your most important quality indicator.

- Maintain Positive Pressure: Ensure the furnace's gas control system is maintaining a slight positive pressure at all times.

The Importance of Proactive Maintenance

An industrial furnace is a long-term asset. Protecting its integrity protects your product quality. While our furnaces are designed for long maintenance intervals of 180 days or more, a proactive approach is still essential. This means regular inspections of door seals, thermocouple entries, and any other potential weak points. A well-maintained furnace is a pure furnace. Our designs make these checks simple and fast, ensuring maintenance doesn't get in the way of your production schedule.

Conclusion

In short, gas purity is not a minor detail in bright annealing; it is the core factor that determines product quality and profitability. Controlling oxygen below 10 ppm prevents oxidation, guarantees a product qualification rate over 99%, and provides a decisive competitive edge in the marketplace.