High energy bills from open-air annealing eat into your profits. But what if a more precise process could cut those costs? Bright annealing offers that exact energy-saving solution.

Yes, bright annealing is significantly more energy-efficient. Our specialized bright annealing furnaces at AKS consume 10-17% less natural gas than competitors, using just 25–27 m³/t. This efficiency comes from a controlled atmosphere and advanced heat recovery, directly lowering your operational costs.

As a General Manager, I talk to plant directors every day who are focused on ROI and competitiveness. The debate between these two annealing methods comes up often. So, let's break down the real differences and see how switching to a precision process is a strategic investment in your plant's future.

What are the fundamental differences between bright annealing and open air annealing?

Choosing the right annealing process can be confusing. Making the wrong choice leads to poor product quality and unnecessarily high costs. Understanding the core differences is the first step.

The fundamental difference is the atmosphere. Bright annealing uses a controlled, protective atmosphere to prevent oxidation, creating a clean, bright surface. In contrast, open-air annealing exposes hot metal to oxygen, forming an oxide layer that requires costly post-processing like acid pickling.

Let's dive deeper into what this means for your production line.

The Controlled Atmosphere Advantage

The "bright" in bright annealing comes from the result. Because we perform the heating and cooling in a sealed furnace with a protective atmosphere—typically a mix of hydrogen and nitrogen—we can keep oxygen levels incredibly low, under 10 parts per million (ppm)[^1]. This environment prevents the metal's surface from reacting with oxygen, so there's no scale or discoloration. For materials like stainless steel (grades 201, 304), copper, and brass, this is critical. It means the product that comes out of the furnace is the final product, ready for the next stage. This is how we help clients achieve product qualification rate[^2]s over 99%.

The Post-Processing Problem

With open-air annealing, the opposite is true. The process is simpler upfront, but it creates a cascade of extra work. The oxide layer that forms must be removed. This usually involves chemical baths like acid pickling, followed by rinsing and drying stations. These steps add significant operational costs, require more factory floor space, introduce environmental and safety concerns, and consume even more energy. By eliminating these steps, bright annealing streamlines the entire production flow.

| Feature | Bright Annealing (AKS) | Open Air Annealing |

|---|---|---|

| Atmosphere | Controlled (<10ppm O2) | Ambient Air (Oxygen-rich) |

| Surface Finish | Bright, clean, no oxide | Oxidized, scaled surface |

| Post-Processing | None required | Acid pickling, cleaning needed |

| Best For | Stainless Steel, Copper, Brass | Less sensitive, lower-grade metals |

How does energy consumption differ between bright annealing and open air annealing?

Your furnace's energy bill is unpredictable and high. This volatility makes budgeting a nightmare and erodes your profit margins. The choice of annealing process directly impacts your gas consumption.

The energy difference is significant. Our bright annealing furnaces consume 10-17% less gas than many competing systems. We consistently see consumption rates of 25-27 m³/t, while many open-air processes easily exceed 30 m³/t, representing a major and unnecessary operational cost.

Let's dive deeper into the numbers and what they mean for your bottom line.

A Look at the Numbers

Data tells the real story. In my experience, the single biggest pain point for metal processors is high energy consumption. It's a variable cost that can quickly get out of control. That's why we engineered our furnaces to be exceptionally efficient. The comparison is stark.

| Process Type | Gas Consumption (per ton) |

|---|---|

| AKS Bright Annealing | 25–27 m³ |

| Industry Average / Open Air | 30+ m³ |

A difference of 3-5 cubic meters of gas per ton might not sound like much, but it adds up incredibly fast. For a facility processing our typical monthly capacity of 10,000 tons, saving just 3 m³/t means you save 30,000 m³ of natural gas every single month. That's a direct, measurable impact on your profitability.

The True Cost of Inefficiency

This difference in gas consumption is the primary driver behind the 20-40% reduction in total energy costs our clients report. When you combine the lower gas usage with the complete elimination of energy-hungry post-processing steps like pickling lines and dryers, the savings become a powerful competitive advantage. It's not just about spending less; it's about producing more efficiently and freeing up capital for other investments.

What factors contribute to the 17% energy savings in bright annealing?

You know bright annealing saves energy, but you need to know why. Without understanding the "how," you can't justify the investment to your team or stakeholders. The savings come from specific engineering innovations.

The primary factors are superior thermal management and combustion efficiency. At AKS, we achieve this with our dual-layer heat recovery system, which preheats combustion air, and advanced fuel/air ratio controls that ensure every bit of gas is used to its full potential.

Let's dive deeper into the technology that makes this possible.

Innovation 1: Dual-Layer Heat Recovery

A traditional furnace loses a massive amount of energy through its exhaust stack. We saw this as a huge source of waste. Our engineers developed a dual-layer heat recovery system that captures this high-temperature exhaust gas. This captured heat is then used to preheat the fresh combustion air before it enters the burners. Because the air is already hot, the burners need less fuel to reach and maintain the target annealing temperature. It's a simple, elegant solution that is a major contributor to our industry-leading efficiency.

Innovation 2: Advanced Fuel/Air Ratio Control

Incomplete combustion is another silent profit killer. If your fuel-to-air mixture isn't perfect, you're either wasting fuel or not generating enough heat. Our furnaces use a precision control system that constantly monitors and adjusts this ratio. This ensures we achieve complete combustion, maximizing the heat energy extracted from every cubic meter of gas. This system, combined with our heat recovery technology, is how we guarantee consumption figures as low as 25 m³/t. It also contributes to stable furnace temperatures, which we control within a tight ±3℃ window for consistent product quality.

How can manufacturers transition from open air to bright annealing to achieve energy savings?

Switching your core production process seems daunting and expensive. The fear of disruption and downtime often keeps manufacturers locked into an inefficient, legacy system. But a planned transition makes it manageable and highly profitable.

The transition is a strategic investment in new equipment, not just a purchase. It begins with a thorough audit of your current costs and quality. Then, you work with a partner like us at AKS to design a custom furnace that fits your specific production needs.

Let's dive deeper into what a successful transition looks like.

Step 1: The ROI Analysis

Every major capital expenditure must be justified by data. The first step we take with any potential client is to help them build a clear business case. We analyze their current energy bills, production output, product rejection rates, and post-processing costs. We then model the projected savings based on our furnace's performance metrics: 20-40% lower energy costs, a 10%+ boost in annual production, and a product qualification rate over 99%. This data allows you to calculate a clear payback period and present a compelling argument for the investment.

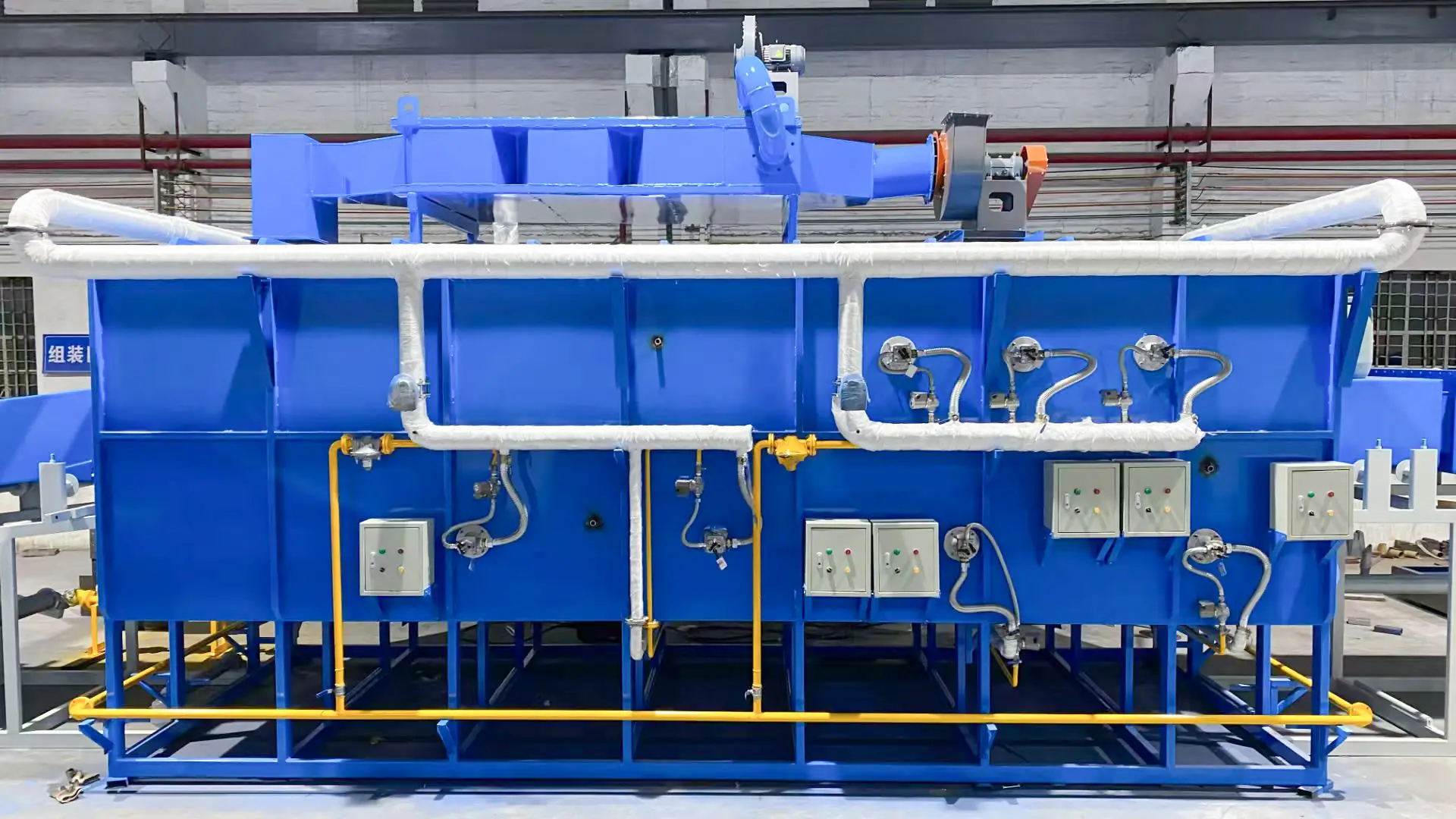

Step 2: The Customization Advantage

One size does not fit all in industrial manufacturing. This is why over 70% of our orders are customized. We address the common pain point where standard equipment just doesn't meet a client's specific needs. My team works with your engineers to design a bright annealing furnace that integrates seamlessly into your existing production line, considering your space constraints, material flow, and output targets. We build the solution for your factory, not the other way around. [Insert anecdote about a client's smooth transition and quick ROI].

What are the best practices for optimizing energy efficiency in bright annealing processes?

You've made the investment in a new bright annealing furnace. But are you getting every bit of efficiency out of it? Following best practices is the key to ensuring you achieve maximum ROI.

Optimization hinges on two things: consistent operation and proactive maintenance. Running the furnace at its designed capacity ensures thermal efficiency. Following our recommended maintenance interval of 180 days or more prevents performance degradation and protects your energy savings with over 98% uptime.

Let's dive deeper into how to get the most from your equipment.

Consistent Production Scheduling

Industrial furnaces are like freight trains; they are most efficient when running continuously. Stopping and starting a furnace, or running it at partial capacity, wastes a tremendous amount of energy during heat-up and cool-down cycles. The best practice is to schedule long, continuous production runs. Our furnaces are designed for stable, 24/7 operation with over 98% uptime, allowing you to plan your production schedule confidently and maximize thermal efficiency. This stability is the foundation of predictable energy costs and high output.

Adhering to Maintenance Schedules

While our furnaces are built for durability with maintenance intervals of 180 days or more, proactive maintenance is non-negotiable. This isn't about frequent downtime; it's about preventing it. Regular checks on door seals, atmosphere sensors, and burner components ensure the furnace remains perfectly sealed and that the fuel/air ratio stays optimized. This simple discipline guarantees that the energy efficiency you invested in on day one is maintained for the entire life of the equipment. It protects your furnace, your product quality, and your bottom line.

Conclusion

Switching to bright annealing is more than a technical upgrade; it’s a strategic business decision. It directly lowers your gas consumption by up to 17%, improves product quality to over 99% acceptance, and boosts overall productivity, future-proofing your operations in a competitive market.