Struggling with surface oxidation and high rejection rates? These issues hurt your bottom line. We have a process that delivers a flawless, bright finish every time, boosting your profitability.

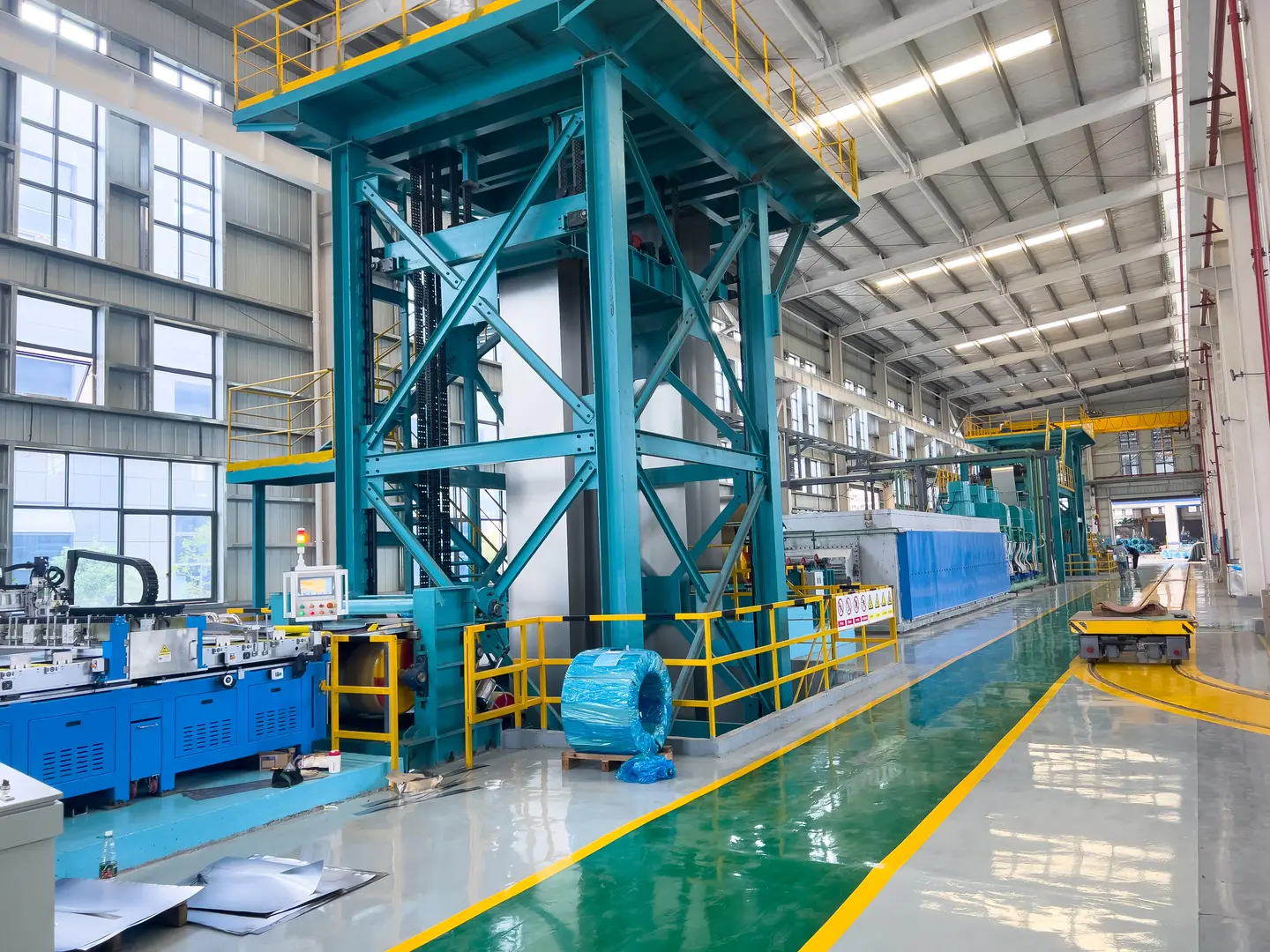

The bright annealing process is a heat treatment method that uses a controlled atmosphere to prevent oxidation, creating a clean, bright surface. The AKS method enhances this by using precise temperature (±3℃) and atmosphere (<10ppm O2) control to achieve product qualification rates over 99%.

I've seen many companies struggle with this. As the General Manager of AKS, I talk to production managers all the time who are frustrated with inconsistent quality and high operating costs. Let's break down how the process works and how our approach at AKS makes a real difference to your production line.

What Exactly is the Bright Annealing Process?

Confused by complex heat treatment terms? You need a clear understanding to make the right equipment choices. Bright annealing is simple: it's about heating and cooling metal without oxidation.

Bright annealing involves heating metal in a furnace with a protective atmosphere, like hydrogen or nitrogen, and then cooling it. This prevents the surface from reacting with oxygen, which keeps it bright and clean, eliminating the need for later cleaning processes like acid pickling.

Let's dive deeper into this. The entire goal of bright annealing is to change the metal's internal structure without messing up its surface. When you process stainless steel, copper, or brass, you introduce stress into the material. Annealing relieves that stress, making the metal softer and more workable for the next production step. But if you do this in a normal atmosphere, the oxygen in the air will cause ugly scaling and oxidation on the surface. Bright annealing solves this.

The Core Components

The process is a careful balance of three things: temperature, time, and atmosphere. You have to get all three right.

| Stage | Purpose | Critical Factor |

|---|---|---|

| Heating | Brings the metal to a specific recrystallization temperature. | Precise and uniform heat. |

| Soaking | Holds the metal at that temperature for a set time. | Stable temperature control. |

| Cooling | Cools the metal down in a controlled way. | Protective atmosphere integrity. |

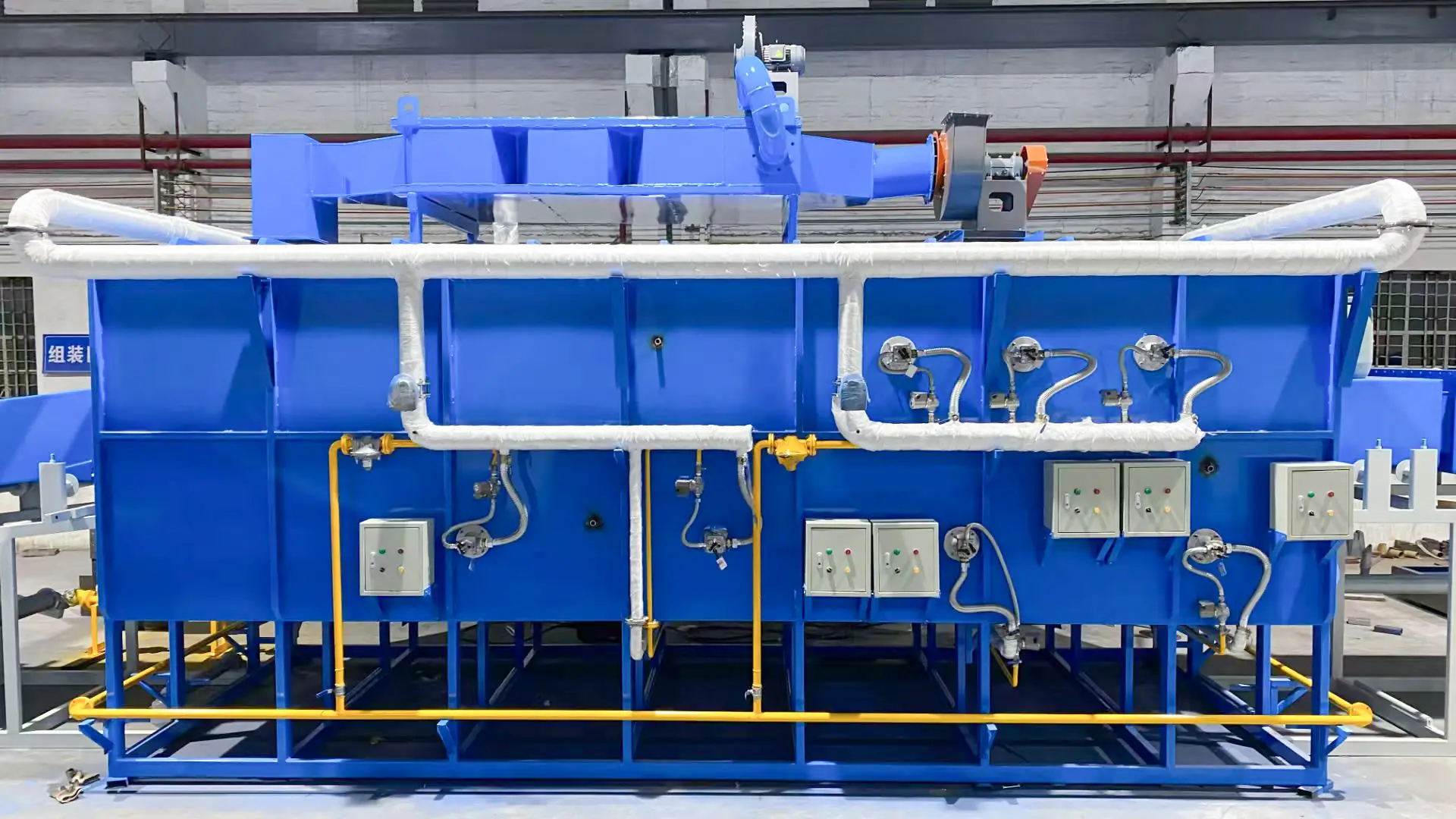

The Protective Shield

The "magic" happens inside a sealed chamber, called a muffle[^1], which is filled with a protective gas. This gas pushes out all the oxygen. At AKS, we design our furnaces to maintain an atmosphere with less than 10 parts per million (ppm) of oxygen. This extreme purity is what guarantees a bright, clean, and valuable final product.

What Are the Current Techniques in Bright Annealing?

Are older furnace technologies holding you back? Outdated methods consume too much energy and deliver inconsistent results. Let's look at the common techniques used today and see where they fall short.

Current techniques include continuous strip annealing lines and batch-type furnaces. Continuous lines are great for high volume, while batch furnaces offer flexibility. However, many older designs lack the precise atmosphere and temperature control needed for the highest quality standards, leading to inefficiencies.

When you look at the equipment on the market, it generally falls into two categories. My team and I have worked with clients using both, and each has its place.

Continuous Furnaces

These are the workhorses of the industry, especially for processing long coils of stainless steel, copper, or aluminum. The metal strip continuously moves through different heating and cooling zones within the furnace. This method is fantastic for high-volume, standardized production. The challenge, however, is maintaining perfect temperature and atmosphere control along the entire length of a very long furnace. Any small deviation can affect a large amount of product.

Batch Furnaces

Batch furnaces are different. You load a part or a set of parts, seal the furnace, run the entire heat-treat cycle, and then unload it. This gives you great flexibility for different product shapes, sizes, or smaller production runs. The main issue I see with older batch furnaces is efficiency. They can have long cycle times and often struggle with heat uniformity, meaning one part of the batch might get treated differently than another. Both techniques rely heavily on the quality of the furnace itself to deliver consistent results.

What Challenges Prevent High-Purity Results?

Facing constant production headaches like high energy bills and product defects? These problems directly link to common furnace challenges. Solving them is key to improving your operation's stability and profitability.

The main challenges are poor atmosphere control, which causes oxidation, and unstable temperature, which leads to inconsistent material properties. High energy consumption, frequent downtime for maintenance, and the inability of standard furnaces to meet specific process needs also severely impact purity and efficiency.

In my experience, almost every production issue in bright annealing comes down to a few core problems. These are the pain points we designed our AKS furnaces to eliminate.

The Top Operational Headaches

| Challenge | Business Impact |

|---|---|

| Atmosphere Leaks | Product oxidation, high rejection rates (>1%). |

| Temperature Fluctuation | Inconsistent mechanical properties, product failure. |

| High Energy Use | Increased operating costs, lower profit margins. |

| Frequent Downtime | Lost production capacity, missed deadlines. |

The biggest enemy of a high-purity finish is oxygen. Even a tiny leak in the furnace muffle can let oxygen in, ruining an entire batch of high-value material. The second enemy is unstable temperature. If your furnace temperature swings by more than a few degrees, you can't guarantee the final grain structure of the metal. This leads to inconsistent quality that your customers will notice. Finally, there's the economic reality. Old furnaces are gas-guzzlers. They also break down often, forcing you into expensive, unplanned downtime. These are not just technical problems; they are business problems that directly affect your bottom line.

How Does the AKS Method Provide an Innovative Solution for Purity?

Are you looking for a reliable way to boost quality and cut costs? Generic solutions don't work. Our method is built on specific innovations designed to solve the core challenges of bright annealing.

The AKS method ensures purity through three key innovations: an advanced fuel/air ratio control for energy efficiency, a precision cooling system for stable temperatures (±3℃), and a dual-layer heat recovery system. This combination guarantees an ultra-pure atmosphere (<10ppm O2) and over 98% uptime.

At AKS, we didn't just build another furnace. We engineered a complete solution. We looked at the biggest challenges our customers face and built technology to solve them directly. Our approach is based on control, efficiency, and reliability.

Precision Control Systems

We use an advanced fuel/air ratio control system. This system ensures the flame is always optimized, providing extremely stable and uniform heat. This is how we achieve a temperature precision of ±3℃ across the entire heating zone. It also means we burn 10-17% less gas than many competitors.

Advanced Thermal Management

Energy cost is a huge factor. That’s why we developed a dual-layer heat recovery system. It captures waste heat from the furnace exhaust and uses it to preheat the incoming air. This simple but powerful innovation is a major reason our clients see their energy costs drop by 20-40%. It's a direct boost to their profitability.

Unmatched Stability and Uptime

Our furnaces are built for tough, 24/7 industrial use. We designed them for stability, achieving over 98% uptime. This reliability means you can run your lines continuously, boosting annual production by over 10%. [Insert anecdote about a client's success in reducing defects]. This level of performance turns your heat treatment process from a cost center into a competitive advantage.

What are the Key Recommendations for Implementing the AKS Method?

Ready to upgrade but unsure where to start? A successful implementation requires more than just new equipment. It needs a clear plan to maximize your return on investment from day one.

To implement the AKS method, first, work with our team to define your specific production needs, as over 70% of our orders are customized. Next, prepare your facility for installation and train your operators on the new control systems. Finally, establish a simple maintenance schedule.

Bringing a new furnace online is a big project. We partner with our clients to make it smooth and successful. Here is the simple, three-step process we recommend.

Step 1: Collaborative Design

We don't believe in one-size-fits-all solutions. Over 70% of the furnaces we build are customized. The first step is for my technical team to sit down with yours. We'll analyze your materials (201, 304 stainless, copper, etc.), your required monthly capacity, and your facility layout. We then design a furnace that is a perfect fit for your operation, ensuring you can meet your production goals, like a capacity of over 10,000 tons per month.

Step 2: Operator Training

Our control systems are modern and easy to use, but proper training is essential to get the most out of them. We provide comprehensive training for your operators. They will learn how to manage the precise temperature and atmosphere controls to consistently achieve product qualification rates over 99%.

Step 3: Proactive Maintenance

Our furnaces are designed for long-term reliability, with a maintenance interval of 180 days or more. We provide a clear and simple maintenance schedule. Following this proactive plan ensures your equipment continues to run at peak efficiency and maintains its high uptime, protecting your investment for years to come.

Conclusion

The bright annealing process is critical for quality. The AKS method delivers superior purity and efficiency by solving core industry challenges. Our technology lowers costs, boosts production, and ensures your products meet the highest standards, giving you a strong competitive advantage in the market.