Have you ever struggled with aluminum that's too hard or brittle for your manufacturing needs? This common issue can lead to production delays and material wastage. At AKS Furnace, we understand that achieving the perfect malleability and ductility in aluminum is crucial for high-quality end products.

Aluminum annealing is a heat treatment process that alters the microstructure of aluminumto reduce its hardness and increase its ductility. This involves heating the aluminum to a specific temperature, holding it there for a certain duration, and then cooling it, making it easier to work with.

Understanding the intricacies of aluminum annealing can transform your production capabilities, leading to improved efficiency and superior product quality. In this article, I'll delve into what aluminum annealing entails, how it functions, and why it's indispensable in modern industry. We'll explore its historical roots, current industrial applications, common challenges, and the strategies and advancements that are shaping its future.

At AKS Furnace, we've seen firsthand how critical precise thermal processing is for aluminum. From aerospace components requiring exacting specifications to everyday items like cookware demanding formability and a pristine finish, annealing plays a pivotal role. This process isn't just about softening metal; it's about unlocking its full potential. We'll examine how factors like temperature control, heating and cooling rates, and atmospheric conditions are meticulously managed to achieve desired metallurgical properties. I'll also share insights gained from our experience in designing and manufacturing advanced annealing furnaces, like our specialized Bright Annealing Furnaces, which are crucial for processing sensitive materials like aluminum strips and foils where surface quality and material consistency are paramount.

What is the historical background of aluminum annealing?

Historically, understanding how to work metals was a trial-and-error process, and aluminum, despite its abundance, was once more precious than gold. Early metallurgists faced challenges in making aluminum malleable enough for widespread use. The solution lay in refining heat treatment techniques, gradually uncovering the principles of annealing.

The historical background of aluminum annealing traces back to the late 19th and early 20th centuries, following aluminum's commercial production. Early efforts focused on empirical methods to soften the metal, evolving with advancements in metallurgical science and temperature control technologies to achieve consistent results.

The journey from aluminum's initial isolation in the early 19th century to its widespread industrial use today is a testament to relentless innovation in metallurgy. Initially, its high reactivity and the difficulty in extracting it made it a rare and expensive material. However, with the development of the Hall-Héroult process in 18861, aluminum production became commercially viable, opening the floodgates for its application. As its use expanded, the need to modify its mechanical properties became evident. Early artisans and manufacturers likely observed that heating and cooling aluminum, much like other metals such as copper and iron, could alter its hardness and workability. These rudimentary forms of annealing were probably discovered by accident or through empirical experimentation. Over time, as metallurgical knowledge grew, these observations were systematized. Scientists began to understand the relationship between temperature, time, and the resulting microstructure of aluminum. This period saw the development of more controlled heating methods, moving from open forges to more enclosed furnaces, which allowed for better temperature regulation, a critical factor in successful annealing. At AKS Furnace, we often reflect on this evolution, recognizing that the sophisticated furnaces we build today stand on the shoulders of these early pioneers who painstakingly refined these heat treatment processes.

The early 20th century marked a significant turning point with the advent of scientific metallurgy. Researchers began to systematically study the effects of annealing on different aluminum alloys, leading to the development of specific annealing cycles for various applications. This era saw the birth of precise temperature control mechanisms and a deeper understanding of phenomena like recovery, recrystallization, and grain growth2 – the core microstructural changes that annealing induces. Industries such as aerospace and automotive, which began to heavily rely on aluminum for its lightweight properties, drove much of this research. They required aluminum with specific strength-to-weight ratios, formability, and corrosion resistance, pushing the boundaries of annealing technology. For instance, a client of ours in the automotive sector, producing intricate aluminum body panels, relies on the precise annealing cycles achievable in our Bright Annealing Furnaces to ensure the aluminum sheets can be deep-drawn without cracking, a capability directly descended from these foundational studies. The development of protective atmospheres in furnaces also became crucial during this period to prevent oxidation and maintain surface quality, especially for alloys that were sensitive to atmospheric contaminants. This historical progression underscores the continuous interplay between industrial demand, scientific understanding, and technological innovation that has shaped aluminum annealing into the sophisticated process it is today.

Understanding Early Aluminum Processing

The initial challenge with aluminum, once it became more accessible after the Hall-Héroult process, was its inherent work-hardening characteristic. As aluminum is rolled, drawn, or formed, it becomes harder and more brittle, making further processing difficult or impossible without risking fractures. Early metalworkers, likely drawing on their experience with other metals, would have experimented with heating aluminum to restore its ductility. These initial attempts were far from precise. Furnaces, if used, offered rudimentary temperature control, and the understanding of soak times and cooling rates was largely empirical.

A significant milestone was the recognition that different aluminum alloys, which began to be developed in the early 20th century to enhance properties like strength or corrosion resistance, required different annealing parameters. For example, duralumin, an early age-hardening aluminum alloy, presented new challenges and opportunities in heat treatment. The historical records and early metallurgical texts show a gradual shift from anecdotal methods to more systematic studies. Researchers like Alfred Wilm, who discovered age hardening in aluminum alloys around 1906, inadvertently contributed to the broader understanding of thermal processing, even if his initial focus was on strengthening rather than just softening.

The impact of this early understanding was transformative. Industries like cookware manufacturing, which relied on the ability to press and draw aluminum into complex shapes, benefited immensely. Imagine a company in the 1920s trying to produce deep aluminum pots; without some form of annealing, their material wastage due to cracking would have been enormous. At AKS Furnace, when we design a Bell-Type Annealing Furnace for a client producing aluminum coils for cookware, we are building upon this century-old legacy of understanding how to make aluminum pliable and ready for such forming operations.

The Role of World Wars in Advancing Annealing

The demands of World War I and, particularly, World War II significantly accelerated advancements in aluminum metallurgy, including annealing. Aircraft construction, a critical wartime industry, relied heavily on lightweight aluminum alloys. The need for high-volume production of consistent quality aircraft components spurred intensive research into optimizing all aspects of aluminum processing, from alloying to heat treatment. Governments and industry collaborated to standardize procedures and improve technologies.

During this period, the understanding of recrystallization kinetics and grain size control in annealed aluminum became much more sophisticated. For instance, ensuring fine, uniform grain structure after annealing was critical for achieving the desired combination of strength and toughness in aircraft skins and structural members. The table below shows a conceptual representation of how annealing parameters affect grain size, a crucial factor understood more deeply during this era.

| Annealing Temperature | Soak Time | Resulting Grain Size | Impact on Properties |

|---|---|---|---|

| Low | Short | Fine | Higher Strength, Toughness |

| High | Long | Coarse | Lower Strength, Softer |

| Optimal | Optimal | Controlled | Desired Balance |

This era also saw improvements in furnace technology. The shift towards electric resistance furnaces and better-controlled gas-fired furnaces allowed for more precise temperature profiles and protective atmospheres, reducing oxidation and ensuring uniformity. A typical scenario we encounter at AKS Furnace, even today, involves clients needing to upgrade older annealing equipment to meet modern standards for precision and efficiency – a direct continuation of the advancements driven by these historical pressures. For instance, a client producing specialized aluminum extrusions for aerospace might require a custom-designed furnace to handle unique profiles while maintaining incredibly tight temperature tolerances, a need born from the stringent requirements of that industry.

Transition to Scientific Annealing Practices

The post-war era saw a consolidation of knowledge and a transition towards more scientifically grounded annealing practices. Metallurgical textbooks began to feature detailed phase diagrams and time-temperature-transformation (TTT) curves for various aluminum alloys, providing engineers with the tools to design precise annealing cycles. The focus shifted towards optimizing processes for energy efficiency, throughput, and specific end-use properties.

The development of sophisticated analytical tools, such as X-ray diffraction (XRD) and electron microscopy, allowed researchers to directly observe the microstructural changes occurring during annealing. This provided invaluable feedback for refining annealing models and practices. For example, understanding the exact mechanisms of recovery (the relief of internal stresses) versus recrystallization (the formation of new, strain-free grains) enabled more targeted heat treatments. If an aluminum component only needed stress relief without significant softening, a lower temperature recovery anneal could be employed, saving energy and time.

This scientific approach is embedded in the DNA of modern furnace manufacturers like AKS. When we design a Bright Annealing Furnace for processing thin aluminum strips used in electronics or packaging, the precise control over temperature ramps, soak times, and cooling rates is paramount. These parameters are no longer based on guesswork but on decades of scientific research and empirical validation. We work with clients, for example, a manufacturer of aluminum foil for capacitors, to fine-tune annealing cycles that ensure optimal electrical conductivity and mechanical flexibility, properties directly influenced by the annealed microstructure. This continuous refinement, rooted in historical advancements, allows us to meet the ever-increasing demands for high-performance aluminum products.

Annealing reduces aluminum hardnessTrue

The primary purpose of aluminum annealing is to decrease hardness and increase ductility by altering the metal's microstructure through controlled heating and cooling.

Annealing was discovered in 20th centuryFalse

While systematic understanding developed in the 20th century, basic annealing principles were empirically discovered much earlier through metalworking with other metals like copper and iron.

How is aluminum currently annealed in industrial applications?

Modern industries heavily rely on aluminum's versatility, but this often necessitates altering its mechanical properties to suit specific manufacturing processes or end-use requirements. The problem is achieving this transformation consistently and efficiently on an industrial scale. This challenge leads to the critical question of how annealing is practically implemented.

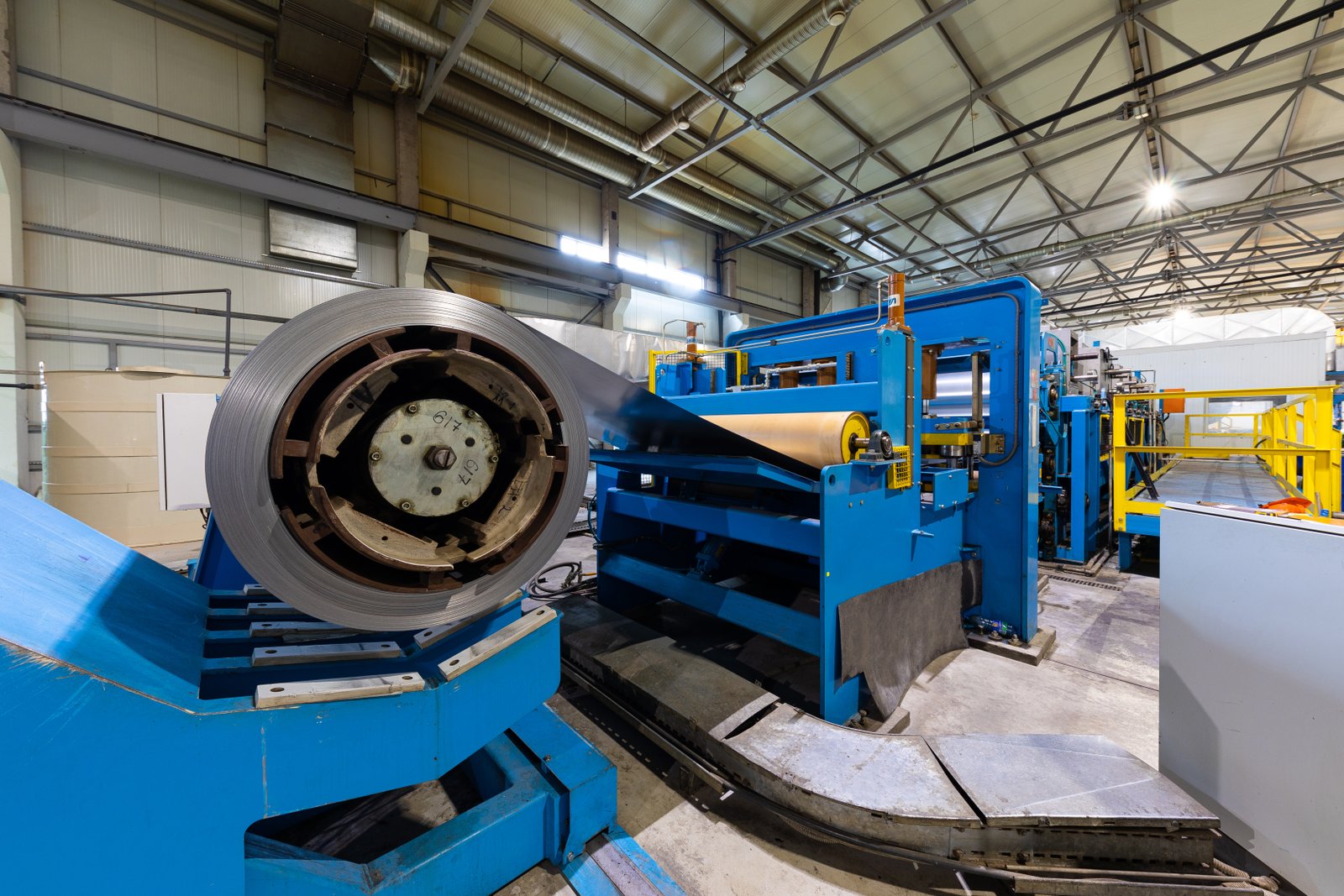

Currently, aluminum is annealed in industrial applications using various specialized furnaces, such as batch furnaces (e.g., bogie hearth, bell-type) or continuous furnaces (e.g., mesh belt, bright annealing lines), employing precisely controlled heating and cooling cycles under specific atmospheric conditions.

The industrial annealing of aluminum today is a highly sophisticated process, far removed from the empirical methods of the past. It involves a deep understanding of metallurgy, thermodynamics, and advanced process control. Depending on the form of the aluminum (e.g., coils, sheets, extrusions, wires, or finished parts), the specific alloy, and the desired final properties, different types of annealing furnaces and process parameters are employed. For instance, at AKS Furnace, we frequently advise clients on the most suitable furnace type for their needs. A manufacturer of stainless steel strip might also process aluminum strip and would benefit from the versatility of our Bright Annealing Furnaces, which can handle various materials by adjusting atmosphere and temperature profiles. The key objectives are always to achieve uniform heating, precise temperature control, controlled cooling rates, and, often, to maintain a bright, oxide-free surface. This requires not only well-designed furnace hardware but also sophisticated control systems that can execute complex temperature cycles with high fidelity. The choice between batch and continuous annealing, for example, depends heavily on production volume, product geometry, and the need for flexibility versus high throughput.

The selection of an annealing furnace and process is a critical decision that impacts product quality, operational efficiency, and cost-effectiveness. For high-volume production of standardized products like aluminum strips or foils, continuous annealing lines, such as our AKS Bright Annealing Furnaces, are often preferred. These furnaces ensure consistent treatment as the material moves through different heating and cooling zones at a controlled speed. The protective atmosphere, typically a mix of nitrogen and hydrogen, is crucial here to prevent oxidation and achieve the bright surface finish desired in applications like reflective sheeting or high-end packaging. For more varied product mixes or larger, bulkier items like large aluminum castings or fabricated structures, batch furnaces such as Bogie Hearth or Bell-Type furnaces offer greater flexibility. A client producing large aluminum alloy components for the transportation industry, for example, might opt for a Bogie Hearth Annealing Furnace due to the size and weight of the parts. Similarly, aluminum wire or coil producers often utilize Bell-Type Annealing Furnaces for their ability to process large batches under a tightly controlled protective atmosphere, ensuring uniformity throughout the coil. The common thread across all these applications is the meticulous control over the annealing cycle – heating rate, soaking temperature, soaking time, and cooling rate – each parameter tailored to the specific aluminum alloy and the desired outcome, whether it's full softening, stress relief, or partial annealing.

Batch Annealing Processes and Equipment

Batch annealing processes are characterized by treating a discrete quantity (a "batch") of aluminum material at a time. This method is highly versatile and suitable for a wide range of product forms, sizes, and production volumes, particularly when flexibility is more critical than continuous high throughput. Common types of batch furnaces include Bogie Hearth Furnaces, Bell-Type Annealing Furnaces, and Box Furnaces. At AKS Furnace, we've supplied Bogie Hearth Furnaces to clients annealing large aluminum castings or fabricated structures that are too bulky or irregularly shaped for continuous lines. The bogie (a movable hearth) allows for easy loading and unloading of heavy charges.

Bell-Type Annealing Furnaces are extensively used for annealing aluminum coils (both wire and strip). The charge is stacked on a stationary base, and a cylindrical or rectangular "bell" containing the heating elements is lowered over it. A separate inner cover is often used to create a sealed environment for a protective atmosphere, which is crucial for preventing oxidation and maintaining a bright surface finish on aluminum coils destined for applications like lithographic sheets or automotive trim. For instance, a typical client producing high-quality aluminum wire for electrical conductors would use a Bell-Type furnace to ensure uniform properties and excellent surface quality throughout the coil. The ability to precisely control the atmosphere (often nitrogen or a nitrogen-hydrogen mix) and the slow, uniform heating and cooling cycles inherent in bell furnaces contribute to superior metallurgical results.

The process typically involves loading the aluminum, sealing the furnace or retort, purging with a protective atmosphere, heating to the annealing temperature (e.g., 340-415°C for many common alloys), soaking for a predetermined time to ensure thorough heating and microstructural changes3, and then controlled cooling. The cooling rate can be critical; for some heat-treatable alloys, slow cooling is necessary to achieve the softest condition, while for others, faster cooling might be acceptable or even desirable to prevent certain precipitations. Data from our installations show that precise control over these parameters in our Bell-Type furnaces leads to a consistent hardness reduction of, for example, from H18 (full hard) to O (fully annealed) temper for 1xxx or 3xxx series aluminum coils, with minimal variation across the batch.

Continuous Annealing Processes and Lines

Continuous annealing is the preferred method for high-volume production of aluminum products with uniform cross-sections, such as strips, foils, and wires. In this process, the aluminum material continuously moves through different zones of a long furnace, each maintained at a specific temperature, allowing for precise control over the heating, soaking, and cooling stages. Our AKS Bright Annealing Furnaces are a prime example of continuous annealing technology, widely used for stainless steel but equally effective for aluminum strip and foil when specific design considerations for aluminum are incorporated. These furnaces typically use a protective atmosphere, such as dissociated ammonia or a nitrogen-hydrogen mixture, to prevent oxidation and ensure a bright, clean surface.

For aluminum strip annealing, the line might include uncoilers, strip cleaning sections, the furnace itself (often with radiant tube heating or direct electrical heating elements isolated from the strip by a muffle to protect the atmosphere), cooling sections (which can be a combination of controlled atmosphere cooling and rapid jet cooling), and recoilers. The speed of the strip, the length of each zone, and the temperature settings are carefully synchronized to achieve the desired annealing effect. For example, a client producing aluminum foil for food packaging needs a very soft, ductile material with a flawless surface. Our continuous bright annealing lines can process thin gauge aluminum foil at high speeds, ensuring uniform properties and a surface ready for printing or lamination. The muffle design in our bright annealing furnaces is crucial for aluminum, as it prevents direct contact between the heating elements and the protective atmosphere, which could otherwise lead to contamination or reactions that affect the aluminum surface.

The advantages of continuous annealing include high throughput, excellent consistency, and reduced labor costs. However, they represent a significant capital investment and are less flexible for small, varied batches. Precise temperature control is paramount. For instance, in a continuous line annealing 5052 aluminum alloy strip for automotive components, the strip might be heated to around 345°C (650°F), soaked for a few minutes as it passes through the hot zone, and then cooled at a controlled rate. Data logging and automated control systems are essential to maintain these parameters consistently, ensuring that every meter of the strip meets the required specifications for ductility and grain size.

Atmosphere Control and Its Importance

Atmosphere control is a critical aspect of modern aluminum annealing, especially when a bright, oxide-free surface is required, or when dealing with alloys sensitive to reactions with air at elevated temperatures. While aluminum naturally forms a tenacious protective oxide layer at room temperature, this layer can thicken and become detrimental during annealing if not controlled, affecting subsequent processing like painting, welding, or anodizing. Protective atmospheres prevent or minimize oxidation and can also help remove residual rolling oils from the surface of the material.

The most common protective atmospheres used in aluminum annealing include pure nitrogen, mixtures of nitrogen and hydrogen (forming gas), or dissociated ammonia (75% hydrogen, 25% nitrogen). The choice depends on the specific alloy, the desired surface finish, cost, and safety considerations. For instance, our Bright Annealing Furnaces at AKS are designed to operate with precise atmosphere control, ensuring very low oxygen and dew point levels. This is particularly important for clients in the electronics or decorative applications markets, where surface appearance and integrity are paramount. For example, a manufacturer of aluminum heat exchanger fins requires a perfectly clean and bright surface for efficient brazing; a controlled atmosphere during annealing is essential to achieve this.

Maintaining the purity of the protective atmosphere within the furnace is crucial. This involves ensuring the furnace is well-sealed, using high-purity gases, and sometimes incorporating gas purification systems. The dew point of the atmosphere4 (a measure of its moisture content) is a key parameter to monitor, as water vapor can be a source of oxygen. The table below illustrates typical atmospheres and their considerations for aluminum annealing:

| Atmosphere Type | Composition | Advantages | Disadvantages | Typical Use |

|---|---|---|---|---|

| Nitrogen (N₂) | >99.9% N₂ | Inert, relatively inexpensive, readily available | Less reducing power than H₂ | General purpose, good for many alloys |

| Forming Gas (N₂/H₂) | 5-25% H₂, balance N₂ | Reducing (H₂ removes oxides), good brightness | H₂ flammability (safety systems needed) | Bright annealing, sensitive alloys |

| Dissociated Ammonia | 75% H₂, 25% N₂ | Highly reducing, cost-effective if NH₃ is cheap | Requires NH₃ cracker, H₂ flammability, N₂ can nitride some alloys if not careful | Bright annealing (less common for Al than steel) |

| Vacuum | <10⁻² mbar | Ultimate protection, no gas costs during process | High capital cost, batch process, slower cycles | High-purity, reactive alloys, aerospace |

At AKS Furnace, our Vacuum Annealing Furnaces also offer an excellent solution for ultra-clean annealing of specific aluminum alloys where even trace atmospheric reactions are unacceptable, though this is more common for specialty metals. The key is matching the atmosphere technology to the client's specific material and quality requirements. For most industrial aluminum annealing, particularly for strip and coil, controlled nitrogen or nitrogen-hydrogen atmospheres in furnaces like our Bright Annealing or Bell-Type units provide the optimal balance of quality, efficiency, and cost.

Continuous annealing is for high-volume productionTrue

Continuous annealing lines are designed for high throughput of uniform products like aluminum strips and foils, offering excellent consistency and reduced labor costs.

Batch annealing uses vacuum exclusivelyFalse

Batch annealing typically uses protective atmospheres (nitrogen/hydrogen mixtures) rather than vacuum, which is reserved for specialty applications requiring ultra-clean results.

What challenges are commonly associated with aluminum annealing?

While aluminum annealing is a well-established process, manufacturers often grapple with achieving consistent results and optimal efficiency. The primary challenge lies in the precise control required over multiple variables, where slight deviations can significantly impact the final product quality. This leads to concerns about yield, energy consumption, and meeting stringent specifications.

Common challenges in aluminum annealing include maintaining precise temperature uniformity, controlling grain growth, preventing surface oxidation or discoloration, managing distortion in thin sections, ensuring complete recrystallization for desired softness, and optimizing energy consumption throughout the process.

Navigating the challenges of aluminum annealing requires a deep understanding of both the material's behavior and the intricacies of thermal processing equipment. At AKS Furnace, we've worked with numerous clients who face these issues daily. For example, achieving uniform temperature throughout a large coil of aluminum strip in a Bell-Type Annealing Furnace can be difficult due to the mass of the material; cold spots can lead to incomplete annealing and inconsistent mechanical properties. Conversely, overheating can cause excessive grain growth, reducing the material's strength and toughness. Preventing surface issues is another major hurdle. Aluminum is highly reactive with oxygen, especially at annealing temperatures. Even with protective atmospheres, improper furnace sealing or incorrect atmosphere composition can lead to surface oxidation, staining, or even undesirable reactions with residual lubricants from prior rolling operations. This is particularly critical for products where appearance or subsequent surface treatments like anodizing are important. We often emphasize that the furnace design itself, including convection patterns and atmosphere flow dynamics, plays a vital role in mitigating these challenges.

Furthermore, the diversity of aluminum alloys adds another layer of complexity. Each alloy system, whether it's a non-heat-treatable series like 1xxx, 3xxx, or 5xxx, or a heat-treatable one like 2xxx, 6xxx, or 7xxx (though full annealing is more common for the former), has its unique response to thermal treatment. Annealing parameters that work perfectly for one alloy can be detrimental to another. For instance, some alloys are prone to "orange peel" defects5 if the grain size becomes too large after annealing, which affects the surface finish after forming. Distortion and warping can also be significant problems, especially when annealing thin gauge sheets, foils, or complex fabricated parts. This is often due to non-uniform heating or cooling, or improper support within the furnace. Energy efficiency is an ever-present challenge, as annealing is an energy-intensive process. Optimizing heating cycles, improving furnace insulation, and utilizing heat recovery systems are crucial for cost-effective operation. At AKS Furnace, we tackle these challenges by incorporating advanced sensor technology, precise PID control algorithms6, and robust furnace construction into our designs, like our Bright Annealing Furnaces that ensure optimal heat distribution and atmosphere integrity for processing sensitive aluminum strips. Our experience shows that a holistic approach, considering material science, furnace engineering, and process control, is essential to consistently overcome these common annealing hurdles.

Ensuring Temperature Uniformity

Achieving and maintaining precise temperature uniformity throughout the entire aluminum charge is arguably one of the most critical and persistent challenges in annealing. Non-uniform temperatures can lead to inconsistent metallurgical properties, with some parts of the material being fully annealed while others remain partially hardened or are over-annealed. This is particularly problematic in batch furnaces treating large or densely packed loads, such as coils of aluminum strip in a Bell-Type Annealing Furnace or stacks of sheets in a Box Furnace. Cold spots within the charge will not undergo complete recrystallization, resulting in higher hardness and lower ductility than desired. Conversely, hot spots can lead to excessive grain growth, surface defects, or even incipient melting in some lower-melting-point alloys.

At AKS Furnace, we address this challenge through several engineering strategies. For instance, in our Bell-Type and Bogie Hearth Annealing Furnaces, we incorporate powerful convection fans to enhance heat circulation within the protective atmosphere, ensuring that heat is distributed more evenly throughout the load. The placement and zoning of heating elements are also carefully designed based on computational fluid dynamics (CFD) and thermal modeling to minimize temperature gradients. For continuous furnaces like our Bright Annealing lines for aluminum strip, the challenge shifts to ensuring uniform temperature across the width of the strip and along its length as it passes through different heating zones. This is achieved through optimized radiant heating designs, muffle integrity, and precise control of strip speed and zone temperatures.

A client producing high-specification aluminum circles for deep-drawn cookware once faced issues with inconsistent earing (the formation of wavy edges) during drawing. Investigation revealed temperature non-uniformity during batch annealing of the sheet stacks. By upgrading to a furnace with enhanced convection and multi-zone temperature control, they were able to achieve a much tighter temperature distribution (e.g., ±3°C throughout the load instead of ±10°C), significantly reducing earing and improving product consistency. This level of precision is vital, as data shows that even a 5-10°C deviation from the target annealing temperature can measurably impact the final grain size and mechanical properties of many aluminum alloys.

Controlling Grain Growth and Microstructure

The primary purpose of annealing is to induce recrystallization, forming new, strain-free grains and thereby softening the material. However, if the annealing temperature is too high or the soaking time too long, these newly formed grains can continue to grow, leading to an undesirably coarse grain structure. Coarse grains can negatively impact several properties: they can reduce the material's toughness, lead to a rough surface finish (known as "orange peel") after forming operations, and sometimes affect fatigue life. Controlling grain growth is therefore a delicate balancing act.

The ideal annealed microstructure typically consists of fine, equiaxed grains. This provides a good combination of ductility for forming and sufficient strength for the application. Factors influencing grain size include the amount of prior cold work (higher cold work promotes finer recrystallized grains), the annealing temperature and time, and the presence of grain refining elements or dispersoids in the alloy. For example, alloys in the 3xxx series (like 3003 or 3105), which contain manganese, have a greater resistance to grain growth compared to purer aluminum like the 1xxx series. At AKS Furnace, when we commission an annealing furnace, we often work with clients to establish optimal annealing cycles that achieve full recrystallization without promoting excessive grain growth. This involves careful testing and metallographic examination of samples annealed under different conditions.

Consider a manufacturer of architectural aluminum panels. If the annealed sheets have too coarse a grain structure, forming complex curves or sharp bends can lead to the orange peel effect, making the surface aesthetically unacceptable and potentially requiring costly rework. By precisely controlling the soak time at the optimal annealing temperature (e.g., 345°C for 3003 alloy, held just long enough for full recrystallization), they can maintain a fine grain size (e.g., ASTM grain size 7-9). The table below shows a simplified relationship:

| Parameter | Effect on Recrystallized Grain Size | Implication for Control |

|---|---|---|

| Prior Cold Work | Higher CW → Finer Grains | Ensure consistent cold reduction before annealing |

| Annealing Temperature | Higher Temp → Coarser Grains (if over-soaked) | Precise temperature control, avoid overheating |

| Soaking Time | Longer Time → Coarser Grains | Optimize soak time for full recrystallization only |

| Alloy Composition | Grain refiners inhibit growth | Understand alloy-specific behavior |

Our advanced furnace control systems allow for precise execution of these optimized cycles, ensuring consistent microstructural outcomes batch after batch, or continuously in the case of strip annealing.

Preventing Surface Oxidation and Contamination

Aluminum is a reactive metal that readily forms a protective aluminum oxide (Al₂O₃) layer when exposed to oxygen. While this layer provides excellent corrosion resistance at room temperature, its uncontrolled growth at annealing temperatures can lead to a dull, discolored surface, or a thicker, harder oxide that can interfere with subsequent operations like welding, brazing, painting, or anodizing. Furthermore, residues from rolling lubricants or other surface contaminants can break down at high temperatures, causing staining or reacting with the aluminum surface.

This is why protective atmospheres are crucial in many aluminum annealing applications, particularly for bright annealing. At AKS Furnace, our Bright Annealing Furnaces are designed with gas-tight muffles or retorts and sophisticated atmosphere control systems to maintain very low oxygen and moisture levels (low dew point). Typically, a nitrogen-based atmosphere with a small percentage of hydrogen (forming gas)7 is used. The hydrogen acts as a reducing agent, helping to prevent oxidation and even slightly reduce any existing thin oxides, resulting in a bright, clean surface. For example, a client producing aluminum strips for reflective lighting fixtures relies on the exceptionally bright surface achieved in our furnaces. Any dullness or discoloration would render the product unusable.

Beyond the atmosphere, furnace cleanliness and proper material preparation are also key. Residual rolling oils should be minimized or effectively removed before or during the early stages of heating. Some modern continuous annealing lines incorporate pre-cleaning sections. In batch processes, slow heating ramps can allow volatiles to escape before they can cause staining at higher temperatures. The choice of lubricant used in prior cold working processes can also impact surface quality after annealing; low-residue, easily vaporized lubricants are preferred. We often advise clients on these upstream considerations, as the furnace can only do so much if the incoming material is heavily contaminated. For instance, data suggests that maintaining an oxygen level below 20 ppm and a dew point below -40°C in the furnace atmosphere is often necessary to achieve a truly bright finish on sensitive aluminum alloys.

Temperature uniformity is critical in annealingTrue

Even small temperature variations (±5-10°C) can significantly impact aluminum's grain size and mechanical properties.

All aluminum alloys anneal identicallyFalse

Different aluminum alloy series (1xxx, 3xxx, 5xxx vs 2xxx, 6xxx, 7xxx) require unique annealing parameters and respond differently to thermal treatment.

What strategies can be employed to overcome these annealing challenges?

Facing inconsistencies in annealed aluminum properties, high energy costs, or surface quality issues can be frustrating and detrimental to a business's bottom line. Manufacturers often feel stuck, unsure how to reliably improve their annealing outcomes. The key lies in adopting a multi-faceted approach to process optimization.

Strategies to overcome aluminum annealing challenges include implementing advanced process control systems for precise temperature and atmosphere management, optimizing furnace design for uniform heating and efficient energy use, meticulous material preparation and handling, and tailored annealing cycle development based on alloy type.

To effectively tackle the common hurdles in aluminum annealing, a proactive and systematic strategy is essential. At AKS Furnace, we believe this starts with a thorough understanding of the specific challenges faced by our clients, whether it's temperature non-uniformity, undesirable grain growth, or surface defects. One core strategy is the adoption of advanced process control. This means moving beyond simple thermostat-based controls to sophisticated PLC or SCADA systems8 that allow for programmable, multi-segment annealing cycles with precise PID regulation of temperature in multiple zones. These systems can also integrate control and monitoring of the protective atmosphere, including flow rates, pressure, and dew point. For instance, a client annealing large, dissimilar aluminum fabrications found that by retrofitting their bogie hearth furnace with multi-zone control and programmable recipes, they could tailor cycles to each load, significantly improving consistency. Another crucial strategy involves optimizing the furnace design itself. This includes features like high-velocity convection fans, strategically placed heating elements, advanced insulation materials to reduce heat loss, and efficient sealing mechanisms to maintain atmosphere integrity and prevent air ingress.

Material preparation and handling also play a vital role. Ensuring that aluminum entering the furnace is clean and free from excessive lubricants or contaminants can prevent many surface-related issues. For coils, proper winding tension is important to allow for even heat penetration and atmosphere circulation. Tailoring the annealing cycle – the heating rate, soak temperature, soak time, and cooling rate – to the specific aluminum alloy and its prior processing history is fundamental. This often requires metallurgical expertise and empirical testing. For example, an aluminum strip producer aiming for a specific temper in a 5xxx series alloy might work with our team to develop a precise continuous annealing profile in one of our Bright Annealing Furnaces, balancing throughput with the need for complete recrystallization and controlled grain size. Furthermore, regular furnace maintenance, including calibration of thermocouples, inspection of seals, and cleaning of the furnace interior, cannot be overstated as a strategy to ensure ongoing optimal performance. By combining these approaches – advanced control, optimized furnace design, careful material handling, and scientifically developed cycles – manufacturers can significantly enhance the quality, consistency, and efficiency of their aluminum annealing operations. We've seen clients reduce reject rates by over 15% and energy consumption by up to 10% through such comprehensive strategies.

Advanced Process Control and Monitoring

Implementing advanced process control and monitoring systems is a cornerstone strategy for overcoming many aluminum annealing challenges. Traditional annealing setups often rely on basic temperature controllers, which may not provide the precision or responsiveness needed for modern quality standards, especially with sensitive aluminum alloys or complex load geometries. Modern systems, often PLC-based (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) integrated, offer multi-zone temperature control, programmable heating and cooling ramps, and precise soak time management. This allows for the creation of highly specific annealing recipes tailored to different alloys and product requirements.

At AKS Furnace, our annealing furnaces are equipped with such advanced controls. For example, our Bright Annealing Furnaces for aluminum strip feature multiple heating and cooling zones, each independently controlled and monitored. Thermocouples are strategically placed to provide real-time temperature feedback from various points within the furnace and on the strip itself (using non-contact pyrometers where appropriate). This data is fed into PID (Proportional-Integral-Derivative) control loops9 that make micro-adjustments to power output, ensuring the temperature profile is meticulously followed. Furthermore, these systems log all critical process parameters – temperatures, atmosphere flow rates, dew point, strip speed, etc. – creating a detailed record for quality assurance and process analysis. A client producing automotive aluminum components was able to trace an intermittent formability issue back to slight temperature deviations during the soak period by analyzing such logged data, allowing them to fine-tune their recipe and eliminate the problem.

Atmosphere control is another area where advanced systems provide significant benefits. Integrated sensors can monitor oxygen levels, dew point, and gas composition in real-time, automatically adjusting gas flow rates to maintain the desired protective environment. This not only ensures consistent surface quality but also optimizes the consumption of expensive protective gases. For instance, a Bell-Type Annealing Furnace for aluminum coils can be programmed to use a higher purge flow initially and then reduce it to a maintenance level once the desired atmosphere purity is achieved, saving significant operational costs without compromising quality.

Furnace Design and Optimization

The physical design of the annealing furnace plays a critical role in addressing challenges like temperature uniformity, energy efficiency, and atmosphere integrity. Optimizing furnace design involves careful consideration of insulation materials, heating element types and placement, internal gas circulation, and sealing mechanisms. Modern refractory and insulating materials, such as ceramic fibers and microporous insulation, offer superior thermal efficiency compared to older brick-lined furnaces, reducing heat loss to the surroundings and thus lowering energy consumption.

At AKS Furnace, we invest heavily in R&D for furnace design. For example, to improve temperature uniformity in our Bogie Hearth and Bell-Type Annealing Furnaces, we incorporate high-capacity, strategically placed convection fans and baffle systems. These create forced convection currents within the furnace chamber, ensuring that the protective atmosphere (and thus heat) is circulated effectively around and through the load. This helps to minimize hot and cold spots, particularly in densely packed charges like aluminum coils. The table below highlights some design features and their benefits:

| Furnace Design Feature | Benefit | Impact on Annealing Challenge |

|---|---|---|

| High-Efficiency Insulation | Reduced heat loss, lower energy consumption | Addresses energy inefficiency |

| Multi-Zone Heating Elements | Precise temperature control in different furnace sections | Improves temperature uniformity, allows complex profiles |

| Convection Fans/Baffles | Enhanced heat transfer and atmosphere circulation | Greatly improves temperature uniformity, reduces cycle times |

| Gas-Tight Muffle/Retort | Maintains protective atmosphere integrity, prevents contamination | Prevents oxidation/discoloration, ensures bright surface |

| Optimized Sealing Systems | Minimizes air ingress and protective gas leakage | Improves atmosphere control, reduces gas consumption |

| Heat Recovery Systems | Preheats combustion air or incoming load using exhaust gas energy | Further enhances energy efficiency |

For continuous annealing lines, like our Bright Annealing Furnaces, the design of the muffle (if used) or the radiant tube system is crucial. The muffle must be completely gas-tight to separate the heating elements from the protective atmosphere and the aluminum strip. Its material must withstand high temperatures and thermal cycling without distortion or degradation. The strategic placement of entry and exit seals (e.g., felt seals, dynamic gas curtains) is also critical to minimize atmosphere loss and air ingress, which is vital for maintaining low dew points and oxygen levels essential for bright annealing of aluminum.

Alloy-Specific Annealing Cycles and Material Preparation

Developing and implementing annealing cycles specifically tailored to the aluminum alloy being processed, its temper, and its intended application is a fundamental strategy. There is no one-size-fits-all annealing recipe. Different aluminum alloys (e.g., 1xxx, 3xxx, 5xxx, 6xxx series) have different recrystallization temperatures, grain growth kinetics, and sensitivities to cooling rates10. For instance, some 5xxx series alloys, if not cooled properly after annealing, can be susceptible to sensitization, which affects their corrosion resistance. Heat-treatable alloys like 6061, if given a full anneal, require very slow cooling to achieve the softest 'O' temper.

At AKS Furnace, we often collaborate with clients to conduct trials and develop optimal annealing parameters. This might involve metallographic analysis of samples annealed under various conditions to assess grain size, hardness testing, and formability tests. For example, a client processing aluminum strip for deep drawing applications needed to achieve maximum ductility. By carefully adjusting the soak temperature to just above the full recrystallization point and optimizing the soak time to ensure complete recrystallization without significant grain growth, coupled with a controlled cooling rate, we helped them achieve a consistent elongation value improvement of 5-8%.

Material preparation is an equally important, though sometimes overlooked, aspect. The condition of the aluminum before it enters the furnace significantly impacts the annealing outcome. This includes the amount of prior cold work (which influences recrystallization behavior), surface cleanliness (residual oils or contaminants can cause staining or interfere with atmosphere reactions), and proper loading techniques to ensure good heat and atmosphere exposure. For coils, consistent winding tension is important. For stacked sheets, ensuring adequate spacing for atmosphere circulation can be beneficial. Educating operators on these best practices is a key part of a comprehensive strategy to overcome annealing challenges. For example, implementing a simple pre-cleaning step for heavily oiled aluminum strip before it enters a continuous annealing line can dramatically improve surface brightness and reduce furnace contamination.

Advanced control improves annealingTrue

PLC and SCADA systems enable precise temperature and atmosphere control, leading to more consistent annealing results.

All alloys need same annealingFalse

Different aluminum alloys require tailored annealing cycles due to varying recrystallization temperatures and cooling requirements.

What technical advancements enhance the effectiveness of aluminum annealing?

Manufacturers constantly seek ways to improve their annealing processes, aiming for better quality, higher efficiency, and reduced costs, but sometimes existing technologies reach their limits. The challenge is to identify and adopt new advancements that can provide a genuine leap forward. Innovations in control, materials, and modeling are paving the way.

Technical advancements enhancing aluminum annealing include sophisticated sensor technology for real-time monitoring, advanced simulation software for process optimization, innovative furnace materials for better thermal efficiency and longevity, and integrated automation systems for improved consistency and reduced human error.

The quest for perfection in aluminum annealing is an ongoing journey, propelled by continuous technological innovation. At AKS Furnace, we are always exploring and integrating new advancements to provide our clients with state-of-the-art solutions. One of the most impactful areas is sensor technology. Modern sensors go beyond basic thermocouples; they include non-contact pyrometers for accurate surface temperature measurement of moving strips, in-situ oxygen and dew point analyzers for precise atmosphere control, and even advanced acoustic or vibrational sensors that can provide insights into equipment health. This wealth of real-time data, when fed into intelligent control systems, allows for dynamic adjustments to the annealing process, ensuring optimal conditions are maintained. For example, if a dew point sensor in our Bright Annealing Furnace detects a slight increase in moisture, the control system can automatically increase the flow of dry protective gas to compensate, preventing potential surface oxidation on the aluminum strip. This level of responsiveness was simply not possible with older technologies.

Another significant advancement lies in the realm of simulation and modeling software. Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) tools11 allow furnace designers like us at AKS to simulate heat transfer, gas flow dynamics, and thermal stresses within the furnace and the aluminum charge before a furnace is even built. This enables us to optimize heating element placement, fan design, insulation strategies, and even the loading patterns for batch processes to achieve maximum temperature uniformity and energy efficiency. For clients, this means furnaces that perform better from day one. For instance, before manufacturing a large Bogie Hearth Furnace for a client annealing complex aluminum castings, we used CFD modeling to ensure that our convection system design would provide even heating to all parts of the diverse load, preventing warping and ensuring consistent metallurgical properties. Furthermore, advancements in furnace construction materials, such as new ceramic fiber composites and advanced metallic alloys for radiant tubes and muffles, offer improved thermal efficiency, faster heating and cooling rates, and longer service life, reducing maintenance downtime and operational costs. Automation and robotics are also playing an increasing role, from automated loading/unloading systems to fully integrated process lines where annealing is just one step in a seamless manufacturing flow, minimizing manual intervention and enhancing repeatability.

Intelligent Control Systems and AI

The integration of intelligent control systems, often incorporating elements of Artificial Intelligence (AI) and Machine Learning (ML)12, represents a significant leap forward in aluminum annealing. These systems go beyond traditional PID control by learning from past process data to optimize annealing cycles in real time, predict potential issues, and adapt to variations in material or ambient conditions. For example, an AI-powered control system could analyze historical data from thousands of annealing cycles, correlating input parameters (alloy type, coil size, initial temper) with output quality (hardness, grain size, surface finish) and energy consumption. Based on this learning, it can suggest or automatically implement optimized setpoints for new batches, potentially reducing cycle times or energy use while maintaining or improving quality.

At AKS Furnace, while full AI implementation is an evolving field, we are incorporating more sophisticated predictive algorithms into our control systems. For instance, model-predictive control (MPC) can anticipate the thermal response of a large aluminum coil in a Bell-Type Annealing Furnace and adjust heating proactively, rather than reactively, leading to tighter temperature control and potentially shorter soak times. Consider a client annealing various aluminum alloys with differing thermal masses. An intelligent system could automatically adjust the heating ramp rate based on the specific alloy and load configuration, identified via a barcode scan or manual input, ensuring optimal heating without overshoot. This not only improves consistency but also reduces the reliance on highly experienced operators to make manual adjustments.

Furthermore, AI can be used for predictive maintenance. By analyzing sensor data (vibration, temperature, power consumption of components like fans and heating elements), AI algorithms can detect early signs of potential equipment failure, allowing maintenance to be scheduled proactively before a breakdown occurs. This maximizes uptime and reduces unexpected production halts. For example, an abnormal current draw pattern in a heating element bank could trigger an alert, indicating a failing element that needs replacement during the next planned maintenance, preventing a mid-cycle failure that could ruin an entire batch of aluminum.

Advanced Materials for Furnace Construction

The materials used in constructing annealing furnaces have a profound impact on their efficiency, lifespan, and the quality of the annealed product. Recent advancements in refractory materials, insulation, and high-temperature alloys for internal components are enhancing furnace performance significantly. For example, modern ceramic fiber insulation modules and microporous insulation panels offer much lower thermal conductivity and heat storage capacity compared to traditional refractory bricks. This means less energy is wasted heating the furnace structure itself, more heat goes into the aluminum load, and furnaces can heat up and cool down faster, potentially reducing cycle times.

At AKS Furnace, we utilize these advanced materials in critical areas. In our Bright Annealing Furnaces for aluminum strip, the muffle, which isolates the protective atmosphere and the strip from the heating elements, can be constructed from advanced nickel-chromium alloys or even silicon carbide composites for superior high-temperature strength, creep resistance, and resistance to thermal shock. This extends the muffle's life and ensures its integrity, which is vital for maintaining atmosphere purity. The table below compares traditional and advanced insulation:

| Property | Traditional Refractory Brick | Advanced Ceramic Fiber | Benefit of Advanced Material |

|---|---|---|---|

| Thermal Conductivity | Higher | Lower | Reduced heat loss, better energy efficiency |

| Heat Storage Capacity | Higher | Lower | Faster heat-up/cool-down, shorter cycles |

| Weight | Heavy | Light | Easier installation, less structural support |

| Installation | Labor-intensive | Quicker, modular | Reduced installation time and cost |

Radiant tubes, often used in gas-fired bright annealing furnaces, also benefit from material advancements. Tubes made from high-performance alloys like Kanthal APM or APMT offer longer life at higher operating temperatures and better resistance to carburization or oxidation, leading to more reliable and efficient heating. For electric furnaces, heating elements made from materials like molybdenum disilicide (MoSi₂) or silicon carbide (SiC) can operate at higher temperatures and offer longer lifespans than traditional metallic elements in certain atmospheres, although careful selection based on the specific aluminum annealing atmosphere is crucial. These material improvements collectively contribute to furnaces that are more energy-efficient, require less maintenance, and provide a more stable and controlled processing environment.

Simulation and Digital Twin Technology

Simulation software and the concept of a 'digital twin' technology13 are revolutionizing how annealing furnaces are designed, operated, and optimized. Before physical construction, we at AKS Furnace use Computational Fluid Dynamics (CFD) to model gas flow and heat transfer patterns within the furnace design. This allows us to optimize the placement of heating elements, convection fans, and baffles to ensure uniform temperature distribution throughout the load zone. For example, simulating the annealing of a densely packed aluminum coil stack in a Bell-Type Furnace can help identify potential cold spots and allow us to modify the fan design or gas injection points to mitigate them virtually, saving costly trial-and-error on the actual equipment.

Once a furnace is operational, a digital twin – a virtual replica of the physical furnace and process – can be created using real-time sensor data. This digital twin can be used to monitor performance, predict outcomes, and test new annealing recipes or process modifications in a risk-free virtual environment. For instance, if a client wants to anneal a new aluminum alloy or a different product form, we could use the digital twin to simulate the proposed annealing cycle, predict the temperature evolution within the load, estimate the cycle time, and even anticipate potential issues like distortion before running a physical trial. This significantly speeds up process development and reduces material wastage.

Furthermore, digital twins can be invaluable for operator training and troubleshooting. Trainees can interact with the virtual furnace, learning how to operate it and respond to various scenarios without affecting actual production. When a problem occurs in the physical furnace, the digital twin can help diagnose the issue by comparing its simulated behavior based on current setpoints with the actual sensor readings, highlighting discrepancies that could point to the root cause. For example, if the actual heating rate is slower than predicted by the digital twin, it might indicate a failing heating element or an air leak compromising the furnace efficiency. This integration of simulation from design through operation enhances effectiveness by ensuring optimized performance and enabling proactive management of the annealing process.

Modern sensors improve annealing controlTrue

Advanced sensors like non-contact pyrometers and dew point analyzers enable real-time monitoring and dynamic adjustments during aluminum annealing.

Traditional bricks insulate better than ceramicsFalse

Advanced ceramic fiber insulation actually provides superior thermal performance with lower conductivity and heat storage compared to traditional refractory bricks.

Conclusion

Aluminum annealing is a vital metallurgical process, transforming brittle aluminum into a workable material. Understanding its history, modern applications, challenges, and the strategies and technical advancements for optimization allows manufacturers to achieve superior quality, efficiency, and consistency in their products.

-

Discover the breakthrough that made aluminum commercially viable and widely available. ↩

-

Understand the key metallurgical stages that occur during aluminum annealing. ↩

-

Understand how annealing alters aluminum's internal structure to achieve desired softness and ductility. ↩

-

Grasp why controlling moisture in furnace atmospheres is vital for preventing aluminum oxidation and defects. ↩

-

Learn about the causes, appearance, and prevention methods for orange peel defects in metal forming. ↩

-

Understand how PID controllers help achieve precise temperature control in industrial processes like annealing. ↩

-

Discover the composition and benefits of using forming gas for bright annealing of aluminum. ↩

-

Learn how PLC/SCADA systems enhance industrial process automation and control accuracy in annealing. ↩

-

Understand how PID controllers maintain precise temperature stability in annealing processes. ↩

-

Explore key metallurgical factors influencing aluminum annealing outcomes and alloy behavior. ↩

-

Learn about CFD/FEA simulations for optimizing engineering designs and manufacturing processes. ↩

-

Discover applications of AI/ML in optimizing industrial processes and intelligent control systems. ↩

-

Understand how digital twins revolutionize design, operation, and optimization in manufacturing. ↩