Struggling with oxidized, inconsistent copper finishes? These defects hurt your bottom line and damage your reputation. The solution lies in precise control over your furnace's atmosphere during heat treatment.

The best method is using a bright annealing furnace with advanced atmosphere control to ensure oxygen levels remain below 10ppm. This prevents oxidation, guarantees a bright surface finish, and achieves over 99% product qualification rates, directly boosting your operational efficiency and profitability.

As the General Manager of AKS, I've seen firsthand how mastering the furnace environment transforms a business. It’s not just about meeting a technical spec; it's about building a foundation for quality and reliability. Let's explore why this level of precision is so critical for your success in the copper processing industry.

Why is oxygen content critical in copper heat treatment?

Unsure why a few parts per million of oxygen matters? Ignoring this tiny detail leads to scrapped parts, wasted energy, and lost profits. It's the single most important factor determining your final product quality.

Oxygen content is critical because it directly causes oxidation on the copper surface during heating. This compromises the material's brightness, conductivity, and overall quality. Controlling oxygen is essential for producing high-value, defect-free copper products that meet strict industry standards.

At its core, the problem is simple chemistry. When copper is heated, it desperately wants to react with any available oxygen. This reaction forms copper oxides on the surface. We see this as discoloration, staining, or a dull finish. For industries that rely on a bright, clean surface for aesthetics or further processing, this is a major failure. But it goes deeper than just looks. This precision is not just a technical achievement; it's a strategic lever for growth. When you can guarantee quality at this level, you build a stronger, more competitive business.

The Impact on Surface Finish

The most obvious effect of oxygen is on the surface. A truly "bright annealed" copper product should be just that—bright and reflective. Even a small amount of oxidation can create a hazy or stained appearance, leading to immediate rejection by customers. Achieving an oxygen level below 10ppm is the only way to consistently prevent this.

The Effect on Downstream Processes

For many of our clients, the annealed copper is not the final product. It might be used for wiring, plating, or other applications where surface quality is paramount. An oxidized surface can interfere with soldering, reduce electrical conductivity, and cause issues with coating adhesion. By controlling the atmosphere, we help ensure our clients' products perform flawlessly in the next stage of manufacturing.

What challenges arise from high oxygen levels during copper heat treatment?

Are you experiencing inconsistent results from batch to batch? These variations are likely due to uncontrolled oxygen, costing you significant time and money. Understanding these challenges is the first step to solving them.

High oxygen levels create significant challenges, including severe surface oxidation, inconsistent coloration, and reduced material ductility. This leads to high rejection rates, increased rework costs, and a damaged reputation for quality. It makes stable, predictable production nearly impossible to achieve.

When oxygen isn't precisely controlled, you're essentially gambling with every production run. The results are unpredictable and costly. I remember a client who came to us after struggling with rejection rates as high as 15%. [Insert anecdote about a client's struggle with oxidation before switching to our furnace]. Their old equipment simply couldn't maintain a stable, low-oxygen environment. This instability directly impacted their profitability and their ability to meet customer deadlines. The difference between a high-oxygen and a low-oxygen environment is night and day, not just for the product but for the entire operation.

Operational Instability

In a high-oxygen environment, you're constantly fighting fires. Operators have to tweak settings, production schedules are disrupted by rework, and forecasting becomes a nightmare. This creates a stressful and inefficient workplace.

A Comparison of Environments

The data speaks for itself. Here is a clear breakdown of what you can expect from different operating environments:

| Metric | High Oxygen Environment (>50ppm) | Low Oxygen Environment (<10ppm) |

|---|---|---|

| Surface Quality | Dull, stained, inconsistent | Uniformly bright and clean |

| Rejection Rate | 5-15% or higher | <1% (Our clients achieve >99% qualification) |

| Production Stability | Unpredictable, frequent adjustments | Stable 24/7 operation (>98% uptime) |

| Energy Costs | High due to rework and inefficiency | Lowered by 20-40% |

How can precision control improve the quality of copper heat treatment?

You want better quality, but you're not sure how to get there. Guesswork and outdated equipment won't cut it in today's market. Precision control is the only reliable path to superior, consistent results.

Precision control over temperature (±3℃) and atmosphere (<10ppm O2) directly improves quality by eliminating the root cause of defects: oxidation. It ensures every batch has a uniform, bright finish and consistent mechanical properties. This boosts product qualification rates to over 99% and enhances overall productivity.

At AKS, we've built our Bright Annealing Furnaces around the principle of total control. It's not enough to just get close; you have to be exact. This level of precision is what separates industry leaders from the rest. When C-level executives and production managers ask me how to gain a competitive edge, my answer is always the same: invest in technology that delivers unwavering control. It's the foundation for every other business goal, from increasing market share to maximizing ROI. Our furnaces are designed to be that foundation, providing the stability and precision needed for sustainable growth.

Stable Temperature, Stable Quality

Atmosphere control is only half the battle. Temperature must also be incredibly stable. Our furnaces maintain a temperature variance of just ±3℃. This ensures that the entire copper coil is heated evenly, preventing inconsistencies in grain structure and mechanical properties from one end to the other.

Atmosphere as a Quality Guarantee

Our intelligent atmosphere management system is the key to guaranteeing an oxygen level below 10ppm. We use advanced fuel/air ratio controls and a sealed furnace design to create and maintain the perfect protective environment. This isn't a feature we added on; it's the core of our design. It's how we deliver on our promise of a product acceptance rate over 99%.

What methods are available to achieve <10ppm oxygen content in copper heat treatment?

You know you need low oxygen, but which method is best? Choosing the wrong technology means a wasted investment and continued struggles with quality. The right furnace makes all the difference.

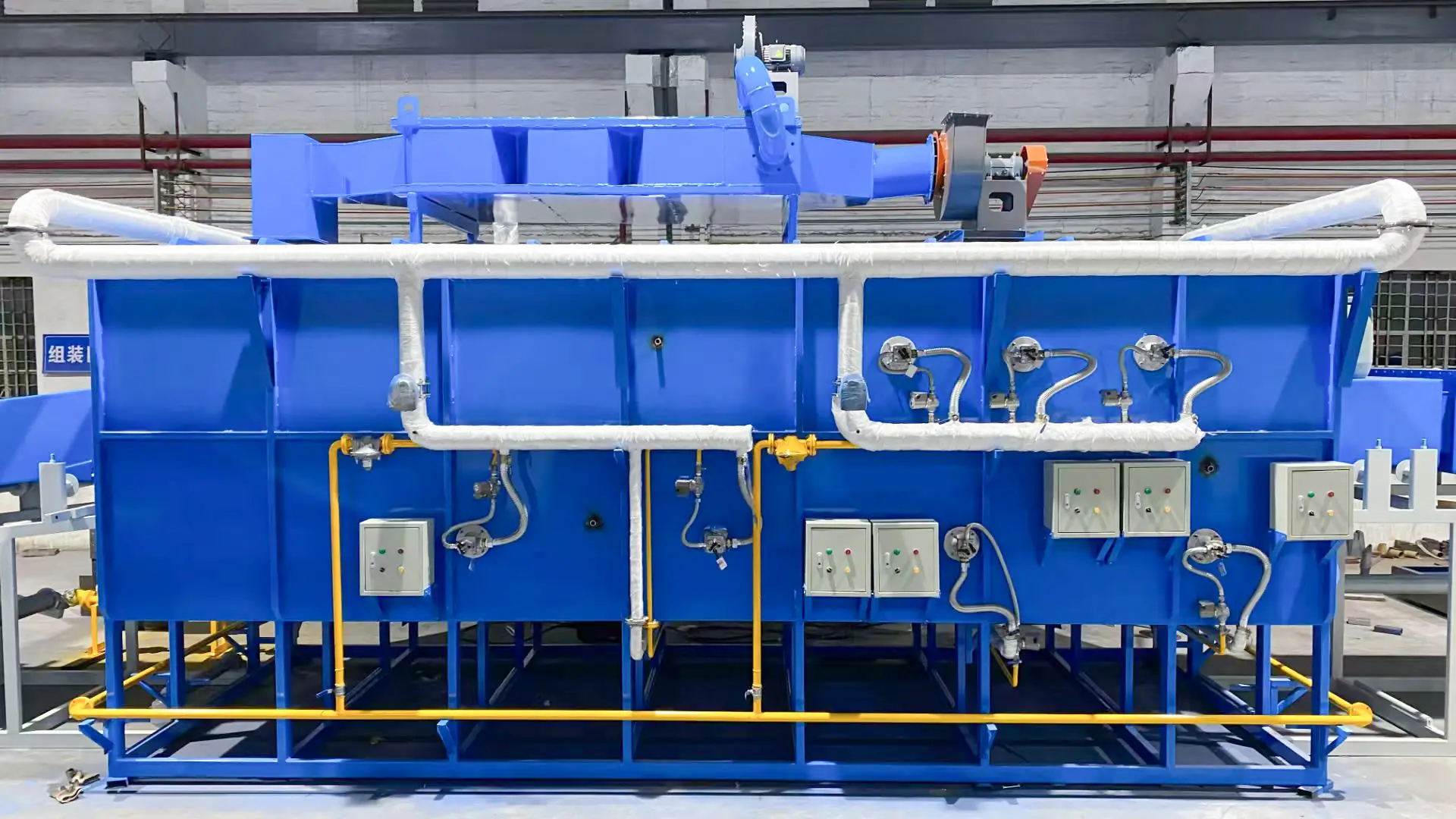

The most effective method is using a modern bright annealing furnace. These systems use a sealed muffle and a protective atmosphere, like cracked ammonia, to purge oxygen. Our AKS furnaces integrate intelligent atmosphere management to guarantee oxygen levels consistently below 10ppm.

The technology to achieve this level of control exists today, but not all furnaces are created equal. Older designs or general-purpose furnaces often have leaks or inefficient atmosphere circulation, making it impossible to hold oxygen levels below 10ppm[^1] reliably. We designed our furnaces specifically for this challenge. It's about creating a completely sealed, controlled system where we dictate the environment, not the other way around. This focus is why over 70% of our orders are customized—we work with clients to build a system that perfectly matches their specific production needs, ensuring they get the results they require.

The Role of the Sealed Muffle

The heart of the system is the sealed furnace chamber, or muffle. This is what contains the protective atmosphere and keeps outside air—and its oxygen—from getting in. We use high-quality materials and advanced welding techniques to ensure our muffles are perfectly sealed for long-term, reliable industrial use.

Our Intelligent Atmosphere Control System

Inside the muffle, we introduce a protective gas. Our system constantly monitors the pressure and composition of this atmosphere, making micro-adjustments to maintain positive pressure and keep oxygen levels near zero. This automated system ensures consistent results 24/7 with minimal operator intervention, contributing to our documented >98% uptime.

What are the best practices for maintaining low oxygen levels in copper heat treatment?

You have the right equipment, but your results still vary. Even the best furnace needs proper operation and maintenance to deliver peak performance. Following a few best practices ensures consistent success.

Best practices include ensuring a perfect furnace seal, maintaining consistent positive pressure with the protective gas, and using high-purity gases. Regular equipment maintenance is also key. Our furnaces are designed for long maintenance intervals of over 180 days, simplifying this process.

We believe that great equipment should be easy to run correctly. Our responsibility doesn't end when the furnace is installed. We design our equipment and provide technical service to make these best practices simple to follow. For us, a successful partnership means our clients are consistently and easily achieving their production goals. That’s why we focused on durability and low maintenance. A furnace that is always down for repairs can't maintain a stable atmosphere. Our design philosophy ensures you spend your time producing high-quality copper, not fixing equipment.

Sealing and Pressure Integrity

Before every run, operators should verify the integrity of the furnace door seals and ensure the protective gas system is supplying consistent positive pressure. This simple check prevents the vast majority of atmosphere-related issues. Our systems include alarms and monitors to make this process foolproof.

Proactive Maintenance Schedules

While our furnaces are built for durability with maintenance intervals of 180 days or more, a proactive maintenance schedule is crucial. This includes inspecting seals, checking gas lines, and calibrating sensors. A well-maintained furnace is a reliable furnace, capable of delivering the <10ppm oxygen environment you need, day in and day out. This reliability is what allows our clients to boost annual production by over 10%.

Conclusion

Achieving <10ppm oxygen content with a modern bright annealing furnace is more than a technical goal; it's a core business strategy. This precision leads directly to superior products, lower operating costs, and a stronger, more competitive position in the market. Our technology at AKS makes it possible.