Unplanned downtime kills your production schedule. Every hour your furnace is offline costs you money and market share. What if your furnace could run for over six months without stopping?

Yes, achieving over 180 days of maintenance-free operation with a bright annealing furnace is a reality. This level of reliability stems from advanced engineering, including robust heat recovery systems and precise atmosphere control, ensuring equipment availability of over 98% and significantly reducing operational costs.

That number—180 days—isn't just a specification. It represents a fundamental shift in how you can run your plant. It's a strategic asset that transforms your operational stability. Let's dig into how we make this possible and what it means for your bottom line.

What are Bright Annealing Induction Furnaces and their applications?

Need a perfect, mirror-like finish on your metal products? Oxidation and surface defects create costly scrap and rework. Our furnaces provide a controlled environment to produce a consistently bright, clean surface.

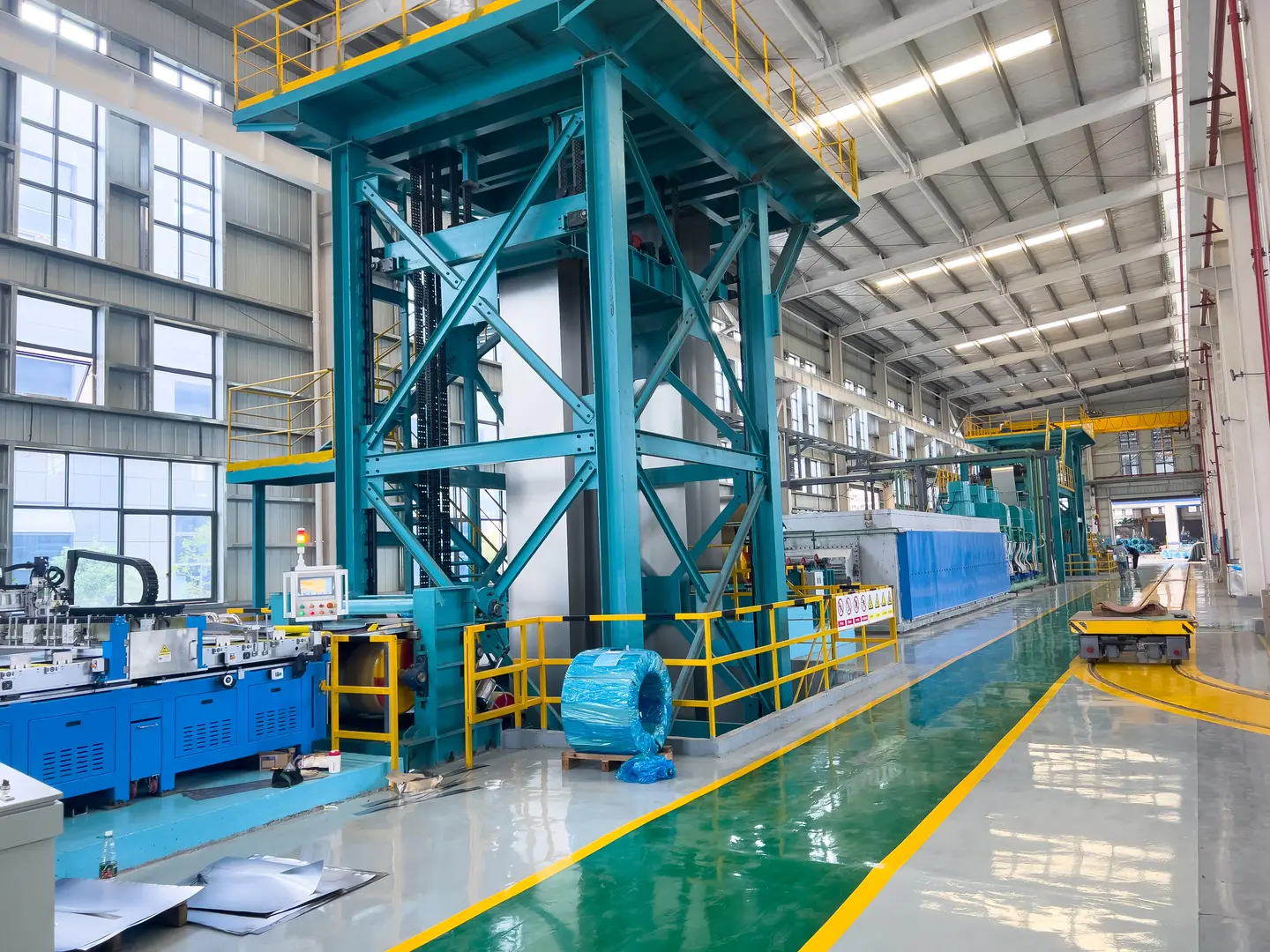

Bright annealing induction furnaces are specialized equipment for heat-treating metals like stainless steel, copper, and brass in a controlled atmosphere. This process prevents surface oxidation, delivering a clean, bright finish essential for high-value applications in automotive, electronics, and precision manufacturing.

The Core Process

At its heart, bright annealing is about control. The goal is to soften the metal, making it easier to work with, without damaging its surface. We achieve this by heating it within a sealed chamber, or muffle. We then fill this muffle with a protective atmosphere, typically a mix of hydrogen and nitrogen. By keeping the oxygen level below 10 parts per million (ppm)[^1], we completely prevent the oxidation that would normally tarnish the metal at high temperatures. This precision is what gives you that "bright" finish and a product qualification rate[^2] of over 99%. It eliminates the need for secondary cleaning processes like acid pickling, saving you time and money.

Key Industrial Uses

The applications are widespread. In the stainless steel industry, our furnaces process coils of 201 and 304 grade steel, preparing them for everything from kitchen appliances to architectural panels. For copper and brass rolling mills, bright annealing is critical for producing wires, tubes, and strips used in electrical components and plumbing. Even aluminum foil manufacturers rely on this process to achieve the right temper and surface quality. In every case, the goal is the same: to produce a high-quality, ready-to-use material that meets exact specifications.

What are the current operational capabilities of Bright Annealing Induction Furnaces?

Are your production targets constantly at risk? Inconsistent furnace performance can derail your entire schedule. We build furnaces for stable, 24/7 operation, giving you predictable output you can count on.

Modern bright annealing furnaces deliver exceptional capabilities, including 24/7 stable operation with over 98% uptime. They maintain precise temperature control within ±3℃ and use 10-17% less gas than competitors, directly boosting annual production by more than 10% while lowering energy costs.

Performance Metrics That Matter

When my team and I talk about performance, we focus on the numbers that impact your business directly. It’s not just about hitting a certain temperature; it’s about doing it efficiently and reliably, day in and day out. We design our systems to deliver concrete results that you can see on your production reports and your energy bills. These aren't theoretical maximums; they are the baseline operational standards we engineer our furnaces to meet and exceed.

| Metric | AKS Furnace Standard | Industry Impact |

|---|---|---|

| Uptime | >98% | Maximizes production hours, reduces lost revenue |

| Temperature Control | ±3℃ | Ensures consistent product quality, reduces defects |

| Atmosphere Control | <10ppm O2 | Guarantees a bright, oxide-free finish |

| Gas Consumption | 10-17% Lower | Lowers operating costs by 20-40% |

| Maintenance Interval | ≥180 Days | Drastically cuts downtime and repair costs |

The Impact on Production

These capabilities translate into a powerful competitive advantage. With a monthly capacity of 10,000 tons or more, our furnaces are built to be the workhorses of your facility. The combination of high uptime and energy efficiency means you can produce more product for less cost. An annual production boost of over 10% isn't just an incremental improvement; it's a significant increase in your plant's total output and profitability.

What challenges complicate maintenance-free operation in these furnaces?

Is frequent, unplanned downtime bleeding your budget dry? The combination of high heat and constant use wears down components. This leads to unexpected stops, expensive repairs, and missed deadlines.

The primary challenges are intense thermal stress on structural components, degradation of heating elements, and atmosphere leaks from failing seals. These issues cause inconsistent product quality, higher energy use, and the frequent, costly downtime that undermines production stability and profitability.

The Battle Against Thermal Stress

A furnace's life is a constant cycle of heating up and cooling down. This expansion and contraction puts enormous stress on every weld, every joint, and every refractory brick. Over time, this thermal cycling leads to metal fatigue and cracks. For many standard furnaces, this is the main reason they require frequent shutdowns for inspection and repair. It's a fundamental physics problem. If the design doesn't account for this stress from day one, you are building in a future failure point. This is one of the most common pain points we hear about from new clients who are struggling with older, less robust equipment.

Maintaining Atmosphere Integrity

The second major challenge is keeping the protective atmosphere sealed inside the furnace. The "bright" in bright annealing depends entirely on keeping oxygen out. Any leak in the seals around doors, sensors, or the muffle itself can compromise the entire batch, leading to oxidation and scrap. High temperatures are brutal on sealing materials, causing them to become brittle and fail. This forces operators into a reactive cycle of constantly chasing down and patching leaks, which is an inefficient way to run a production line. It creates instability and makes consistent quality nearly impossible to achieve.

What are strategic solutions for extending maintenance-free periods in induction furnaces?

Tired of constantly firefighting equipment failures? A reactive approach to maintenance is inefficient and costly. We use a strategic design philosophy that builds reliability in from the start, preventing problems before they happen.

The strategy is rooted in proactive engineering. Key solutions include a dual-layer heat recovery system that minimizes thermal stress and advanced fuel-air ratio controls for stable combustion. This design-for-reliability approach is how we extend maintenance intervals beyond 180 days by intention, not by chance.

Engineering for Endurance

We don't just build furnaces; we engineer solutions to the core challenges of heat treatment. To combat thermal stress, we developed a dual-layer heat recovery system. This innovation doesn't just recycle waste heat to improve energy efficiency; it also preheats incoming air to create a more stable thermal environment inside the furnace. This reduces the severity of temperature swings and, as a result, lessens the physical stress on the furnace structure. It's a simple concept with a powerful impact on long-term durability. We also use higher-grade alloys and advanced refractory materials[^3] in critical areas to ensure they can withstand the demanding 24/7 operational environment.

Smarter Systems, Less Downtime

Durability is also about intelligent control. Our advanced fuel/air ratio control system is a perfect example. It continuously optimizes the combustion process, ensuring we get maximum heat from every unit of gas. This not only cuts energy consumption by 10-17% but also creates a more stable, predictable heating pattern. This stability prevents the hot spots and temperature fluctuations that can damage both the furnace and the product. We also integrate a precision cooling system to manage the cooling phase just as carefully as the heating phase. By controlling the entire thermal cycle with precision, we reduce wear and tear and push maintenance far into the future. [Insert anecdote about a client's success in reducing defects].

What are technical recommendations for optimizing furnace performance and longevity?

Want to get the most out of your capital investment? Even the most advanced equipment performs better with the right operational practices. Simple adjustments can significantly boost efficiency and extend furnace life.

To optimize furnace performance, focus on diligent monitoring of the atmosphere, ensuring oxygen levels stay below 10ppm. Maintain stable temperature profiles within ±3℃ and implement rigorous operator training on startup and shutdown protocols. These practices are key to maximizing longevity and efficiency.

Operational Best Practices

The long-term health of your furnace depends on consistent, disciplined operation. While our systems are highly automated, best practices from your team make a huge difference. Adhering to a strict schedule for checking sensors and calibrating controls ensures the data you rely on is accurate. This allows the system to make the micro-adjustments needed for peak efficiency. We also stress the importance of following the recommended heat-up and cool-down procedures. Rushing these cycles puts unnecessary stress on the equipment and is a leading cause of premature component failure.

| Parameter | Optimal Setting / Practice | Why It Matters |

|---|---|---|

| Atmosphere | Monitor O2 levels; keep <10ppm | Prevents product oxidation and ensures quality |

| Temperature | Maintain stability within ±3℃ | Guarantees consistent metallurgical properties |

| Startup/Shutdown | Follow manufacturer's graded procedure | Minimizes thermal shock and extends component life |

| Data Logging | Regularly review performance logs | Helps identify trends and prevent issues early |

The Power of Customization

Finally, one of the most effective ways to ensure longevity is to use a furnace designed for your specific application. A one-size-fits-all approach rarely works in industrial manufacturing. That's why over 70% of the furnaces we build are customized. We work with you to understand your materials, your production volumes, and your facility constraints. We then design a furnace that is perfectly matched to your needs. This eliminates the inefficiencies and stresses that come from forcing a standard piece of equipment to do a job it wasn't built for. A purpose-built furnace runs smoother, lasts longer, and delivers a better ROI.

Conclusion

Achieving over 180 days of maintenance-free operation isn't a fantasy; it's a strategic reality with the right technology. This level of reliability, with over 98% uptime, cuts operational costs, boosts production, and gives your business a powerful competitive edge in a demanding market.